TM 9-2320-266-34

NOTE

Each used push rod and tappet must be

installed in its original location. New tap-

pets must be installed if a new camshaft is

to be installed.

11-11. Servicing the Camshaft.

The camshaft has an integral gear that drives the distrib-

utor; check the gear for damage. Inspect the camshaft itself

for damage, especially pits and flat spots. Measure the diam-

eters of the journals; if they are out of specification (table

1l-l), replace the camshaft.

11-12. Repair of Damaged or Worn Threads.

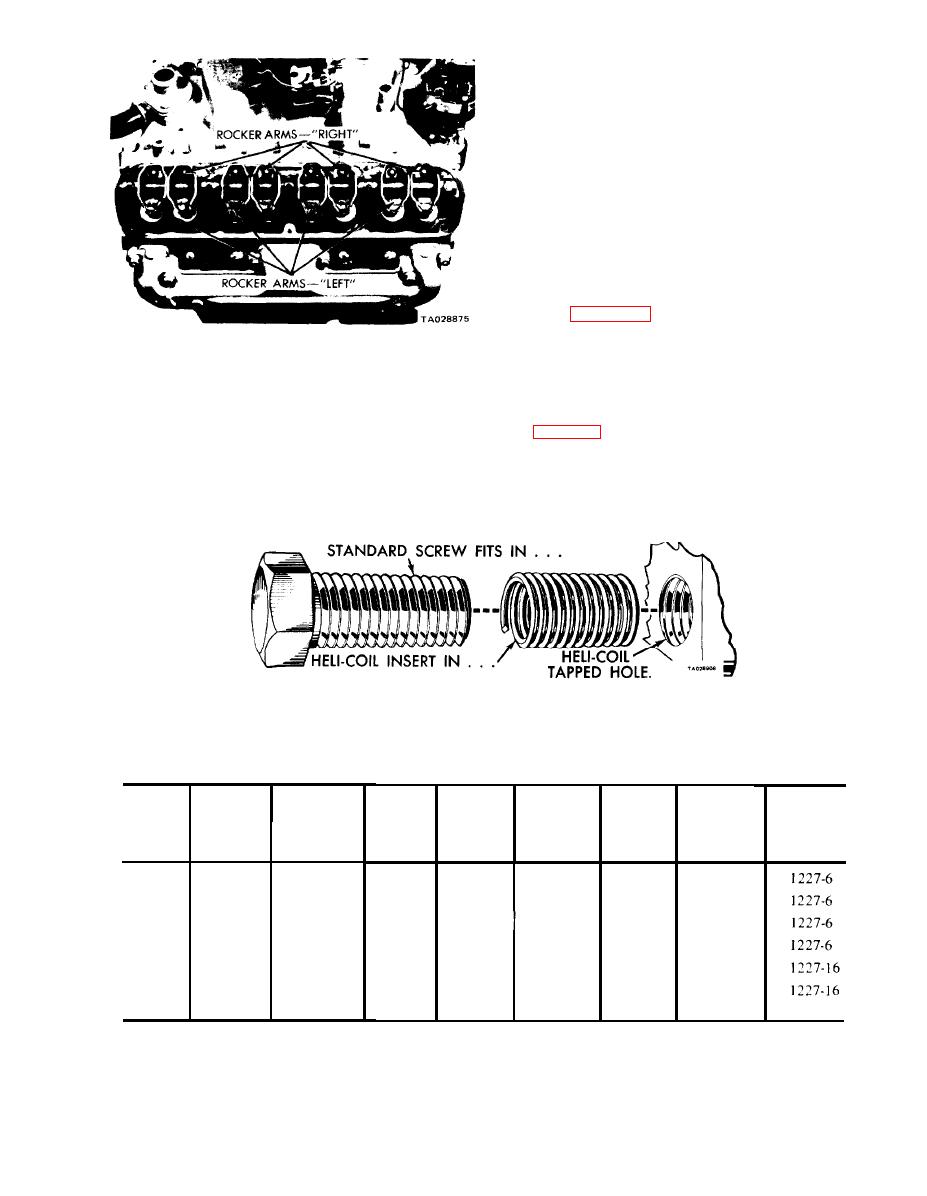

Refer to figure 11-29.

a. Damaged or worn threads can be repaired by using

Figure 11-28. Proper Rocker Arm Location on Shaft.

Heli-Coils or equivalent. This repair consists of drilling out

worn or damaged threads, tapping the hole with a Heli-Coil

11-10. Inspecting the Push Rods and Tappets.

tap, and installing a Heli-Coil insert into the tapped hole.

a. Push Rods. Check for worn or bent push rods; replace

This brings the hole back to its original thread size.

as necessary.

b. Tappets. Unless new tappets (lifters) are being installed,

block. It also gives the necessary tools and inserts for re-

check each tappet face for crown, using a straightedge. If you

pairing damaged or worn threads.

observe any negative crown (or dish), replace the tappet.

Figure 11-29. Heli-Coil or Equivalent Installation.

Table 11-4. HeIi-Coil Chart

Tap

Inserting

part no.

Extracting

Tap

Mopar

Thread

tool

Insert

tool

steel &

Heli-Coil

Drill

part no.

size

part no.

part no.

part no.

length

size

(aluminum)

iron

part no.

10-24

1185-3CN

9/32"

13/64"

3CPB

1187-3

2288-3

1/4-20

11854CN

17/64"

22884

5-40

3/8"

4CPB

1187-4

5-41

5/16-18

1185-5CN

21/64"

42187-5

2288-5

15/32"

5CPB

3/8-16

5-42

1185-6CN

9/16"

2288-6

25/64"

42187-6

6CPB

2288-7

7/16-14

5-43

1185-7CN

29/64"

7CPB

42187-7

21/32"

42187.8

2288-8

1/2-13

5-44

1185-8CN

33/64"*

8CPB

3/4"

17/32"**

*In aluminum

**In cast iron or steel

11-13

441-399 0 - 84 - 10