TM 9-2320-266-34

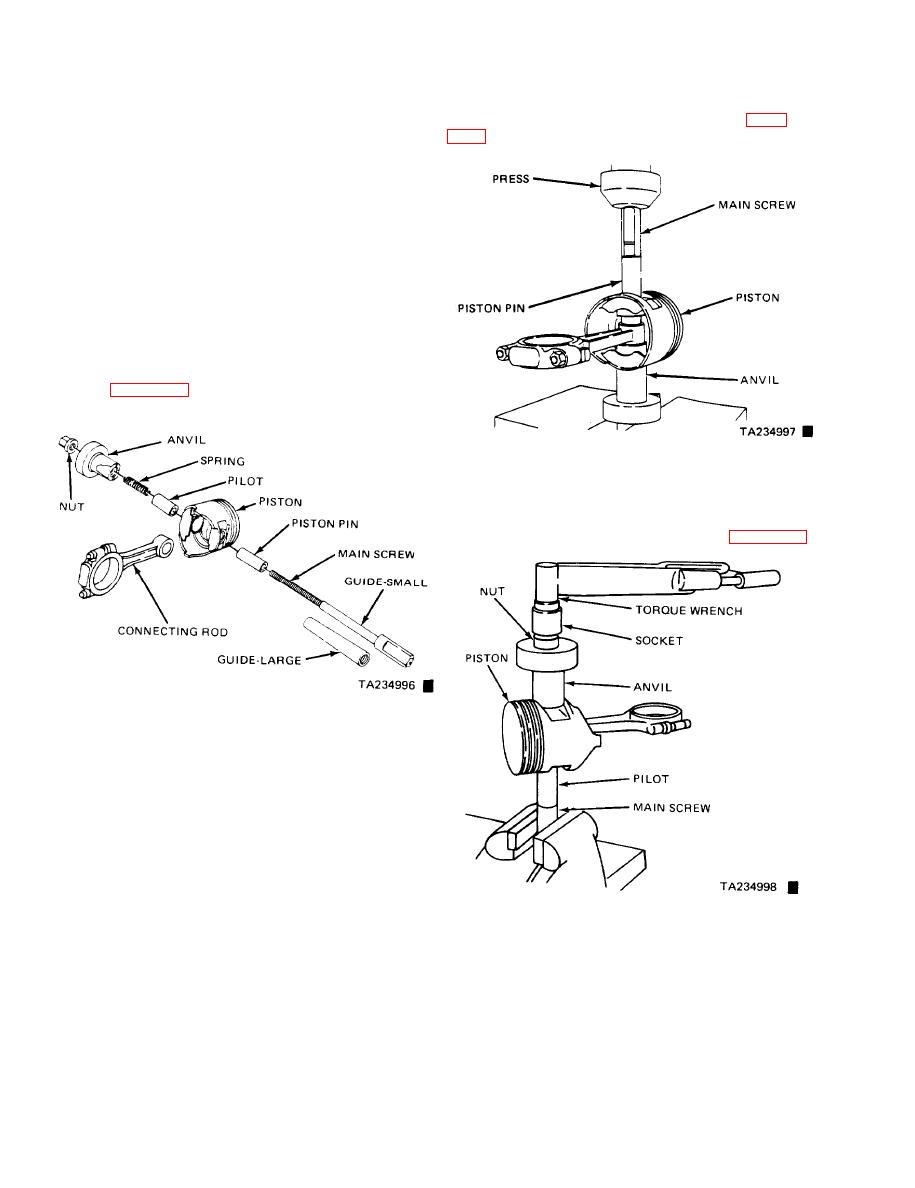

e. Installing Piston Pins. The piston pin rotates in the

(9) Install the nut on the puller screw to hold the

piston only, and is retained only by the interference fit of

assembly together. Place the assembly on a press (figure

the piston pin in the connecting rod. No locks are used in

the piston to retain the piston pin. Tool C4158-L is required

to install the piston pin. The pilot tool C4200-3 and anvil

tool C4200-1 are also required, and are used with tool

C4158-L. Install the pin as follows:

(1) Test the piston pin fit in the piston prior to

assembling the piston `and connecting rod. The pin should

be a sliding fit in the piston. If a new pin fits loosely, the

piston and pin assembly must be replaced.

(2) Lubricate the pin holes in the piston and connect-

ing rod.

(3) Select the appropriate pilot and anvil for use with

tool C4158-L.

(4) Arrange tool C4158-L for installation of the pis-

ton pin (figure 11-12).

Figure 11-13. Installing Piston Pin with Tool C-4158-L.

(10) Press the piston pin in until the pin bottoms on

the pilot. This will position the pin in the connecting rod.

(11) To measure pin fit, remove the tool and arrange

tool parts and the piston assembly as shown in figure 11-14.

Figure 11-12. Arrangement of Tool C-4158-L for Installing

Piston Pin.

(5) Install the spring inside the pilot and install the

spring and pilot in the anvil. Install the piston pin over the

main screw.

(6) Place the piston, with the front up, over the pilot

so the pilot extends through the piston pin hole.

(7) Position the connecting rod over the pilot which

extends through the piston pin hole.

NOT E

Figure 11-14. Testing Piston Pin Fit in Connecting Rod.

Assemble the rods to the pistons of the

right cylinder bank (2, 4, 6, and 8) with the

indent on the piston head opposite the

to 15 ft-lbs. The connecting rod should not move. If it

large chamfer on the large bore end of the

moves, obtain a connecting rod with the proper small end

connecting rod. Assemble the rods to the

bore diameter and repeat the installation and tightening

pistons of the left cylinder bank (1, 3, 5,

procedure.

and 7) with the indent on the piston head

f. Fitting Rings.

on the same side as the large chamfer on

(1) Use an inverted piston to push the rings down to

the large bore end of the connecting rod.

insure positioning the rings squarely in the cylinder bore be-

fore measuring. Measure the piston ring gap when the ring

(8) Install the main screw and the piston pin in the

piston.

Change 7

11-8