TM 9-2320-266-34

(4) Remove the valves; tag them to insure installation

(c) Move the valve to and from the indicator. The

in their original location.

dial indicator reading should not exceed 0.017 inch. Ream

the guides for valves with oversize stems if the dial indicator

c. Inspecting the Valves.

reading is excessive.

(1) Clean the valves thoroughly and discard any burned,

warped, or cracked valves.

NOTE

(2) Measure the valve stems for wear. A new intake

Service valves with oversize stems are avail-

valve stem diameter should measure 0.372 to 0.373 inch and

able in 0.005, 0.015, and 0.030 inch over-

the exhaust valve stem diameter should measure 0.371 to

size. Reamer sizes to accommodate the

0.372 inch. If wear exceeds 0.002 inch, replace the valve.

oversize valve stem are set forth in table

11-3.

(3) Remove carbon and varnish deposits from the in-

side of the valve guides.

Table 11-3. Reamer Sizes

(4) Measure the valve stem guide clearance as follows:

Valve guide

Reamer

(a) Install sleeve tool C-3973 over the valve stem

size

oversize

the valve at the correct height for a dial indicator.

0.379-0.380 in

0.005 in

0.389-0.390 in

0.015 in

0.404-0.405 in

0.030 in

(d) Slowly turn the reamer by hand and clean the

guide thoroughly before installing a new valve.

NOTE

Do not attempt to ream the valve guides

from standard directly to 0.030 inch. If it

is necessary to go to 0.030 inch, use a

step procedure of 0.005, 0.015, and 0.030

inch so the valve guides may be reamed

true in relation to the valve seat.

d. Refacing Valves and Valve Seats.

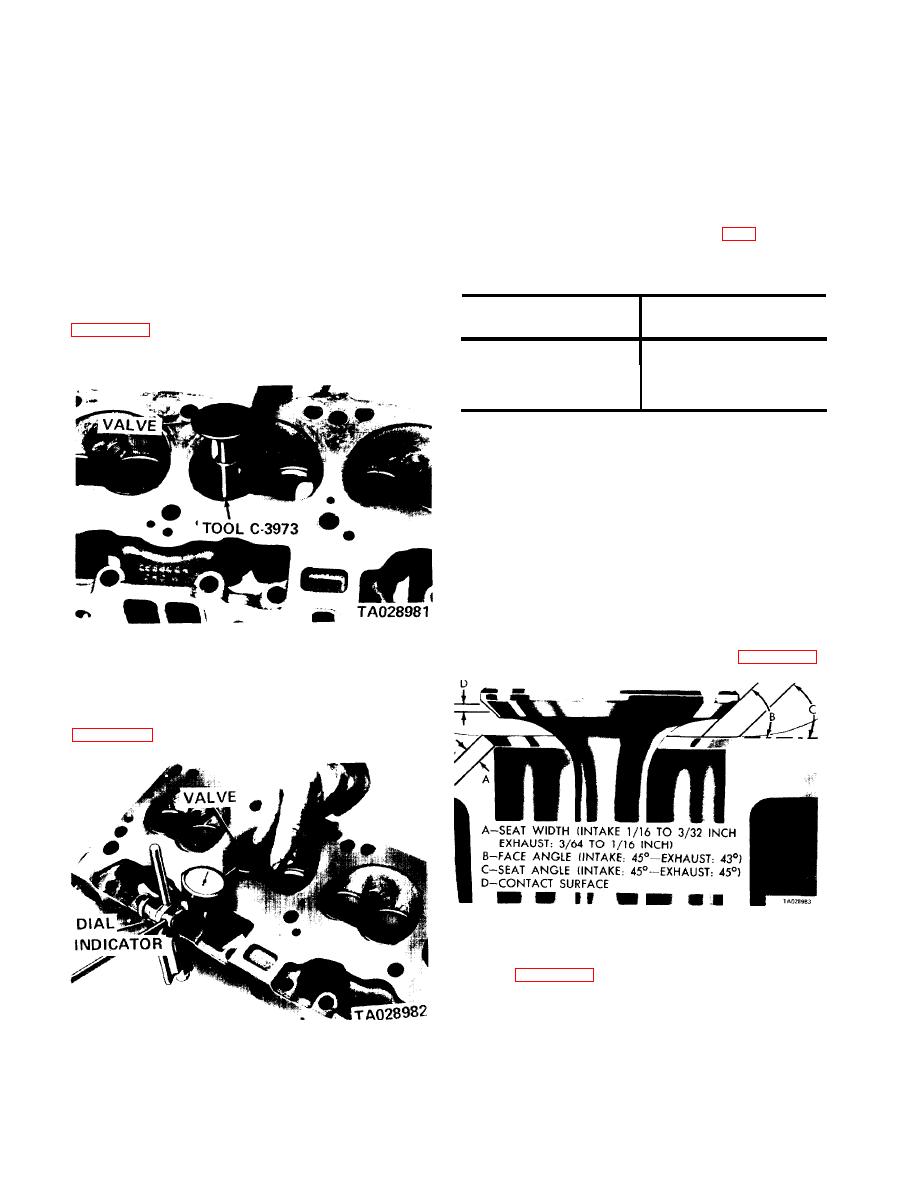

a 45 degree angle. These angles are shown in figure 11-20.

Figure 11-18. Installing Valve and Tool C-3973.

(b) Attach a dial indicator to the cylinder head

and set it at a right angle to the valve stem being measured

Figure 11-20. Valve Face and Seat Angle.

(2) Inspect the remaining margin after the valves are

refaced (figure 11-21). Discard any valves with less than

3/64-inch margin.

Figure 11-19. Measuring Valve Guide Wear.

11-10