TM 9-2320-266-34

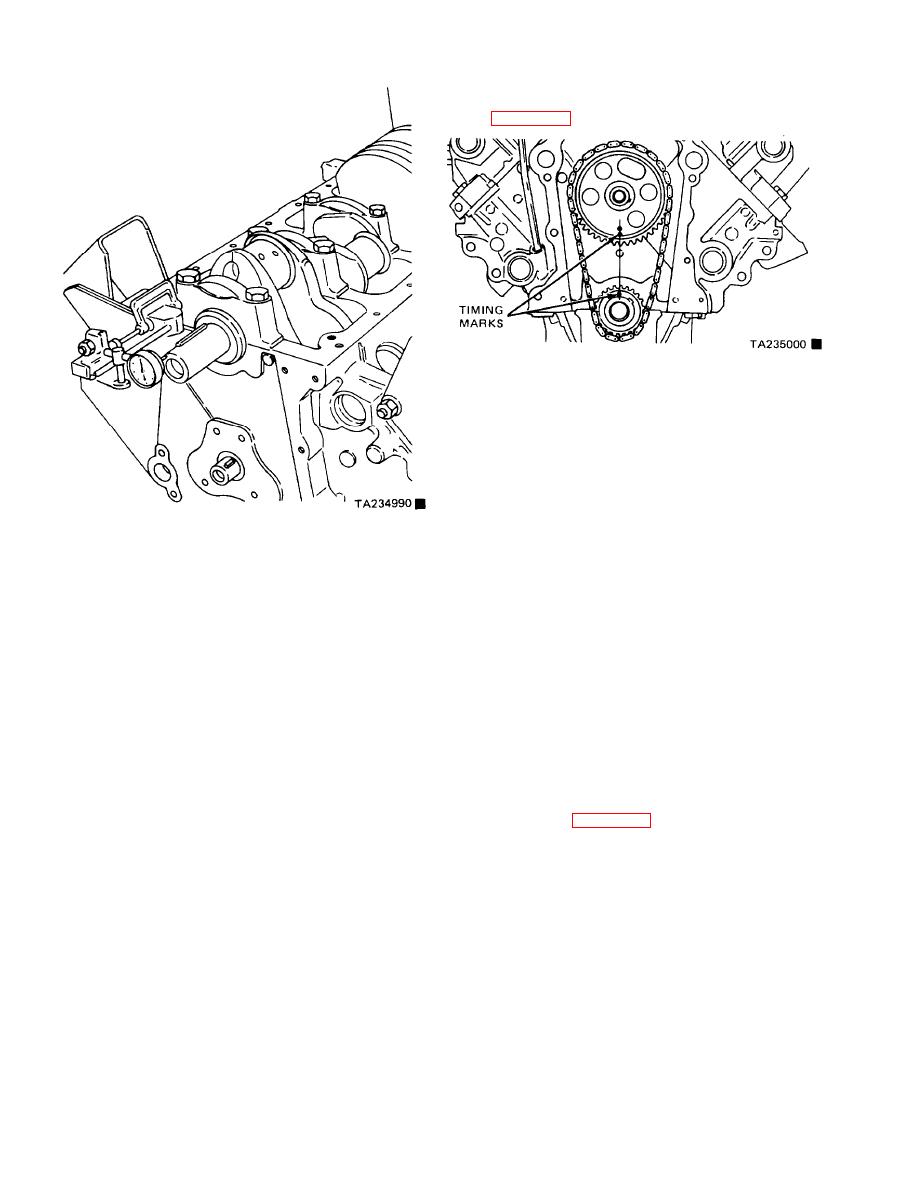

(5) Slide both sprockets evenly over their respective

shafts, and use a straightedge to check alignment of timing

marks (figure 11-37).

Figure 11-37. Alinement of Timing Marks.

(6) Install the fuel pump eccentric, cup washer, and

camshaft bolt. Tighten the bolt to 35 ft-lbs.

(7) Using a new gasket, carefully install the chain case

cover. Tighten the chain case cover capscrews to 30 ft-lbs.

b. Harmonic Balancer.

(1) Lubricate the seal lip. Position the balancer hub

slot on the key in the crankshaft, and slide it on the crank-

shaft.

Figure 11-36. Measuring Grankshaft End Play.

(2) Place an installing tool in position and press the

harmonic balancer on the crankshaft.

h. Checking Bearing Clearances. Measure bearing

clearance as follows:

washer and tighten to 135 ft-lbs.

(1) Smooth the edges of a 1/2- by 3/4-inch piece of

brass shim stock, 0.001 inch thick.

attach it with bolts and Iockwashers. Tighten to 17 ft-lbs

(2) Remove the center bearing cap and lower bearing

(200 in-lbs).

shell.

(3) Lubricate the bearing crankshaft and bolts. Posi-

11-17. Piston and Connecting Rod Assembly.

tion the shim stock across the bearing, install the cap, and

a. Preparation

tighten the bolts to 85 ft-lbs.

(4) If a slight additional drag is felt as the crankshaft

blies into the bore, be sure that the compression ring gaps are

is turned (moved no more than one fourth turn in either

staggered.

direction), clearance is 0.001 inch or less, and is considered

satisfactory. If no drag is felt, the bearing is too large; if the

the oil ring expander ends are butted and the rail gaps are

crankshaft cannot be rotated, the bearing is too small. If the

located as shown in figure 11-16.

bearing clearance is not correct, replace the bearing with the

next size, and repeat the check.

(3) Immerse the piston head and rings in clean engine

oil, slide the ring compressor over the piston, and tighten.

b. Installation.

11-16. Timing Chain and Harmonic Balancer.

(1) Install the upper half of the connecting rod

a. Timing Chain

bearing.

(1) Place both the camshaft and crankshaft sprockets

(2) Rotate the crankshaft so that the connecting rod

on the bench with the timing marks on the exact centerline

journal is on the center of the cylinder bore. The notch or

through both camshaft and crankshaft bores,

groove on top of the piston must be pointing toward the

(2) Place the timing chain around both sprockets.

front of the engine.

(3) Turn the crankshaft and camshaft to lineup with

(3) Insert the rod and piston into the cylinder bore

the keyway location in the sprockets.

and tap the piston down, using a hammer handle.

(4) Lift the sprockets and chain (keep the sprockets

tight against the chain in the position described).

Change 7

11-16