TM 9-2320-266-34

Figure 11-34. Removing Camshaft Bearings.

NOTE

The bearing oil holes must be lined up

with the oil passages from the main

bearings. Also, the number two bearing

must index with the oil passage to the left

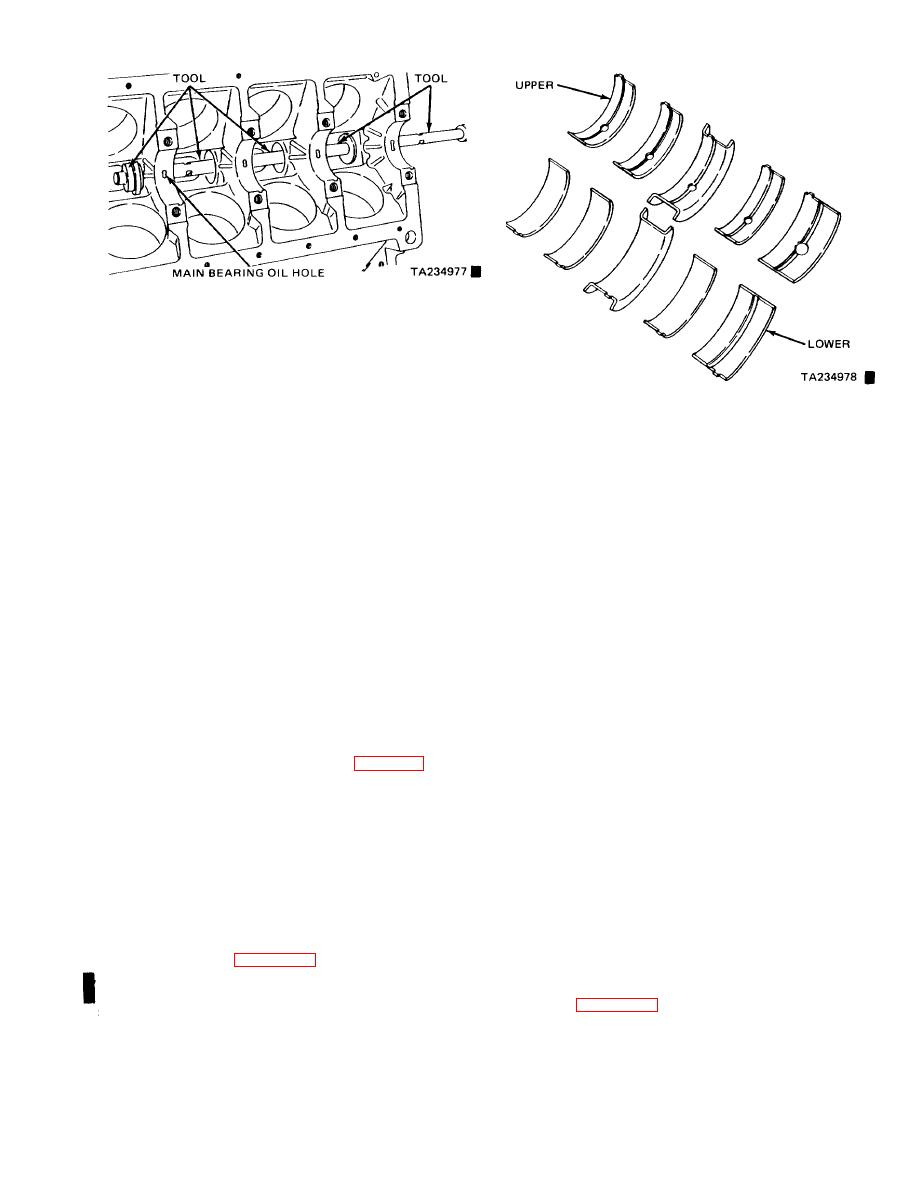

Figure 11-35. Main Bearing ldentification.

cylinder head and the number four bearing

must index with the oil passage to the right

b. Upper Bearing Shells Soak the main bearing shells

cylinder head. If the camshaft bearing

in OE10, then place the upper bearing shells in position in

shell oil holes are not exactly alined, re-

the cylinder block. The upper shells have holes that must

move and install them correctly.

line up precisely with the oil passages.

c. Upper Rear Main Oil Seal

(6) Coat the core hole with sealer.

(1) Install the upper half of the rear main oil seal in

(7) Install a new core hole plug at the rear of the

the cylinder block so that both ends protrude.

camshaft until it is indented 1/64 inch.

(2) Position the seal, using the crankshaft.

c. Installation Procedure

(3) If a rope-type seal is used, art off the portion of

(1) Lubricate the camshaft lobes and bearing journals,

the seal that extends above the block on both sides.

and insert the camshaft to within 2 inches of its final posi-

tion in the cylinder block.

d. Lower Bearing Shells. Install the lower bearing shells

in the bearing caps.

(2) Install tool C-3509 with the tongue in back of the

distributor drive gear. Hold the tool in position with the

e. Lower Rear Main Oil Seal

distributor lock plate screw. This tool will keep the camshaft

(1) Install a new seal in the bearing cap so that the

from being pushed in too far and knocking out the core plug

ends protrude.

in the rear of the cylinder block.

(2) Position the seal so it is seated in the bearing cap.

(3) Install the camshaft thrust plate and the timing

chain oil tab with three screws as shown in figure 11-3.

the seal that extends above the cap on both ends.

Tighten to 18 ft-lbs (210 in-lbs).

f. Bearing Caps

NOTE

(1) While holding the crankshaft in position, install

Make sure the tang enters the lower right

the bearing caps and tighten them finger-tight only.

hole in the thrust plate.

(4) Measure camshaft end play. If the end play is

ft-lbs, working out from the center. Check the crankshaft

more than 0.010 inch, install a new thrust plate.

for free rotation each time a cap is tightened. If the

crankshaft binds, make sure the cap is seated properly and

(5) Remove tool C-3509.

that you have installed the correct size bearing.

11-15. Crankshaft

(3) Repeat the tightening procedure; torque to 50

ft-lbs and then to 85 ft-lbs.

bearings. Bearings are available in standard and 0.010 inch

g. Checking Crankshaft End Play. Measure the crank-

undersize. When installing a new upper bearing shell,

shaft end play (figure 11-36). It should be a minimum of

slightly chamfer the sharp edges from the plain side.

0.002 inch and a maximum of 0.009 inch.

Change 7

11-15