TM 9-2320-266-34

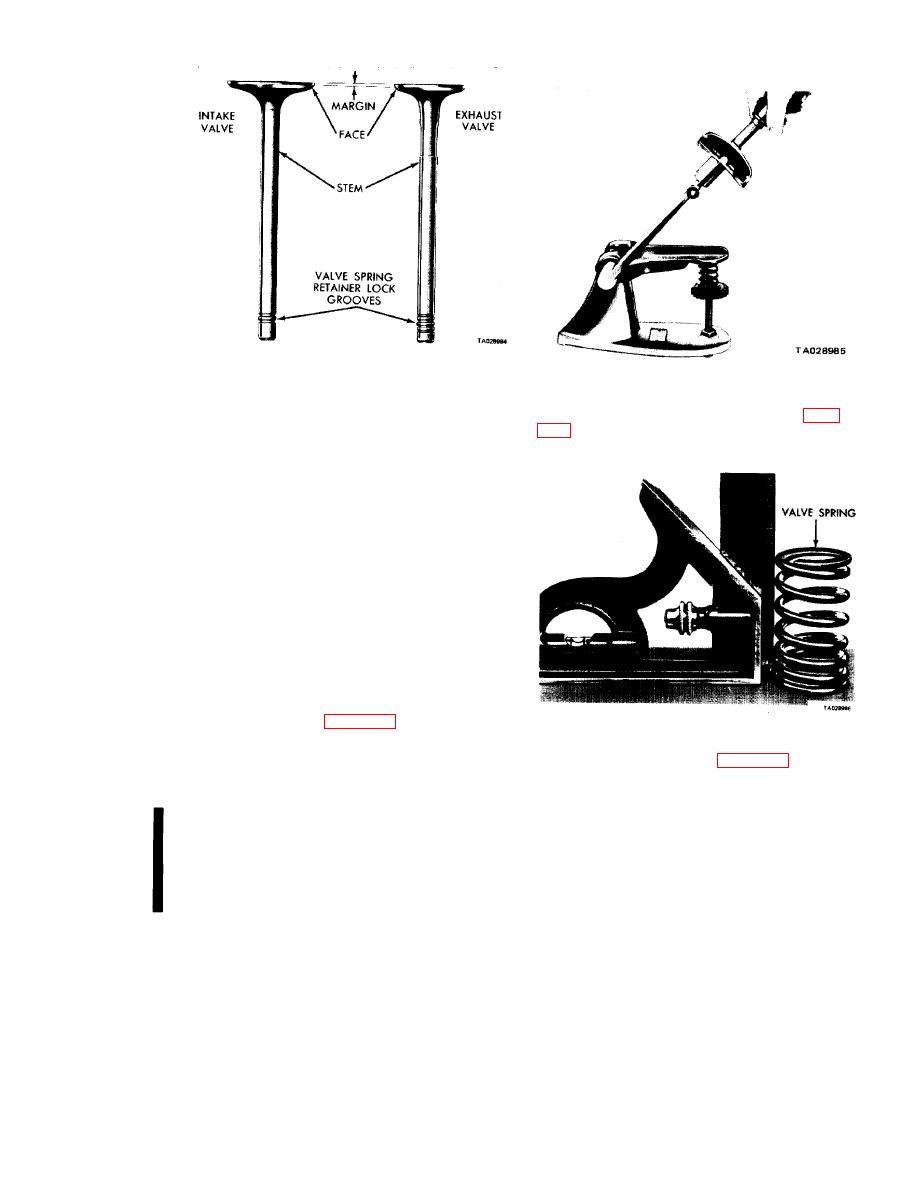

Figure 11-21. Intake and Exhaust Valves.

Figure 11-22. Testing Valve Springs,

(3) When refacing the valve seats, it is important to

(3) lnspect for squareness. Check each valve spring for

use the correct size valve guide pilot for reseating stones. A

squareness with a steel square and a surface plate (figure

true and complete surface must be obtained.

(4) Measure the runout of the valve seat using a dial

square.

indicator. Total runout should not exceed 0.002 inch.

(5) Check the valve seat with Prussian blue to deter-

mine where the valve contacts the seat. To do this, coat the

valve seat lightly with Prussian blue then set it in place.

Rotate the valve with light pressure. [f the blue is transferred

to the center of the valve face, contact is satisfactory. If

the blue is transferred to the top edge of the valve face, lower

the valve seat with a 30-degree stone. If the blue is transfer-

red to the bottom edge of the valve face, raise the valve seat

with a 60-degree stone.

(6) When the seat is properly positioned, the width of

intake seats should be l/16 to 3/32 inch. The width of the

exhaust seats should be 3/64 to 1/16 inch.

e. Testing Valve Springs. Test the valve springs when-

ever the valves have been removed for inspection, recondi-

tioning, or replacement.

(1) Intake valve springs. Turn the table of the valve

spring compression tester (figure 11-22) until the surface is

Figure 11-23. Inspecting Valve Spring Squareness.

in line with the 1-1/4 inch mark on the threaded stud, with

the zero mark to the front. Place (he spring over the stud on

the table, and lift the compressing lever to set the tester's

assembled view of the valve assemblies.

tone device. Then pull on the torque wrench until you hear

the tone device ping. The reading on the torque wrench at

this instant should be 88 to 96 ft-lbs (equivalent to 177 to

192 pounds of pressure).

procedure for intake valve springs, but set the table to the

1-5/16 inch mark. When the tester's tone device pings, the

torque wrench reading should be 90 to 97 ft-lbs (equivalent

to 180 to 194 pounds of pressure).

11-11

Change 2