TM 9-2320-266-34

a fiber mallet, tap the drive gear loose from the differential

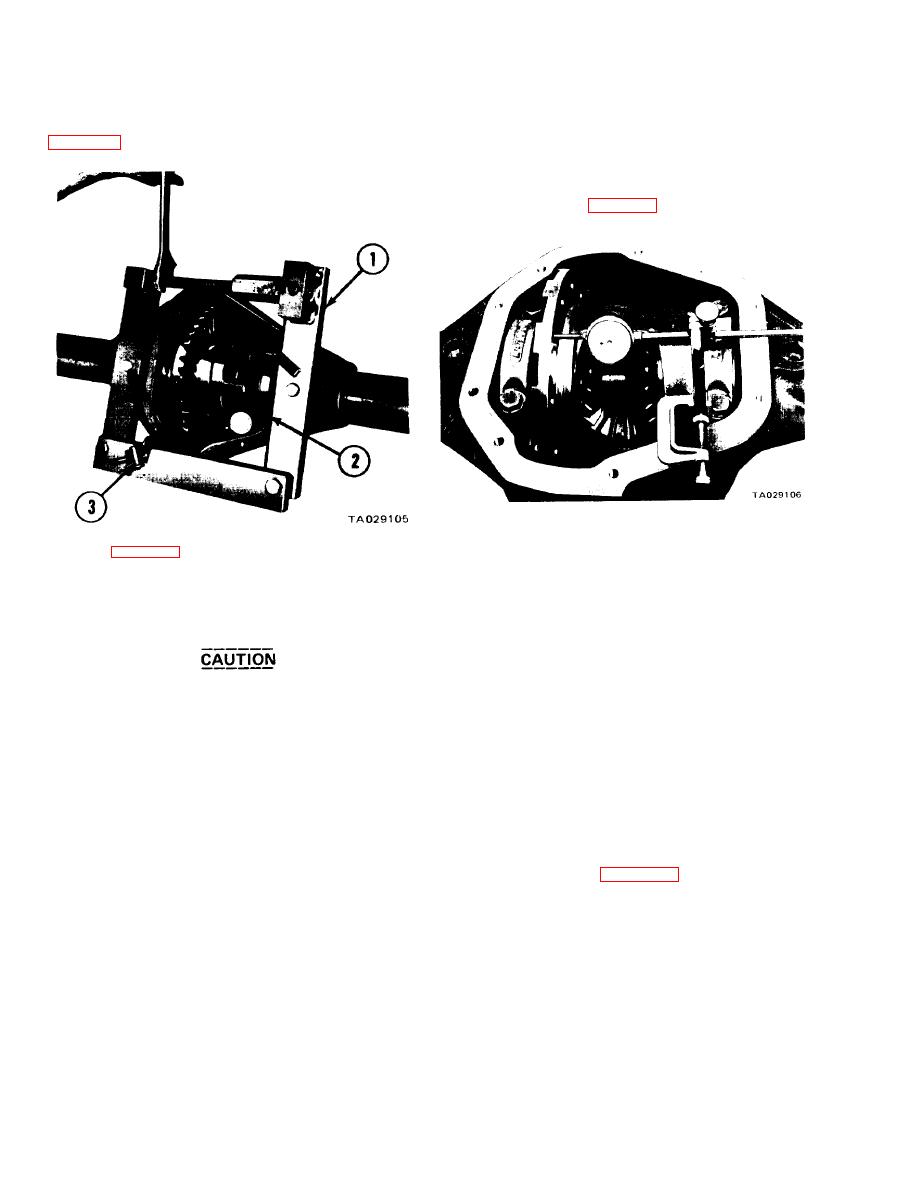

(10) Install the pilot stud on the left side of the axle

case pilot and remove it.

housing. Attach the dial indicator and load the indicator

(14) If the drive gear runout was over 0.006 inch in

stem slightly against the opposite side of the axle housing

step 5, remeasure the differential case flange runout. Install

the differential case with its respective bearing cups in the

axle housing. Loosen the spreader tool nut and remove it.

Install the bearing caps and tighten them snugly. Install the

dial indicator as shown in figure 19-4, and measure the run-

out as described in step 5.

Figure 19-4. Measuring Differential Case Drive Gear

Mounting Flange Face Runout.

Legend for Figure 19-3:

(15) The total allowable runout is 0.003 inch. If runout

1. Spreader W-129-A

is excessive, try positioning the drive gear 180 degrees from

2. Dial indicator and pointer

the point of maximum runout when reassembling the ring

3. Dial indicator clamp

gear on the differential case. Repeat steps 8, 9, 10, and 11

Figure 19-3. Spreading Rear Axle Housing.

above, to see if runout is now 0.003 inch or less.

(16) Position the carrier and tube assembly in the vise

with the nose of the carrier in an upward position. Remove

Do not spread the housing over 0.020 inch,

the drive pinion nut and washer. Using a puller and holding

as it will result in permanent damage to the

tool C-3281, remove the drive pinion flange.

carrier casting.

(17) Using tool C-748, remove the drive pinion oil

(11) Tighten the spreader tool nut until you get a

seal. Remove the slinger, gasket, front pinion bearing cone

0.015-inch movement of the dial indicator, allowing you

and preload shim pack. Record the thickness of the shims in

to remove the differential case and ring assembly. Press

case they should be lost.

down on the opposite side of the spreader while applying

(18) Position the carrier and tube assembly on an

torque; this prevents the tool from popping off.

arbor press. Press out the drive pinion stem and the rear

(12) Remove the dial indicator and the differential

bearing cone assembly.

case and ring gear assembly from the axle housing. A light

(19) Using tool W-100-44-60, remove the front and

prying action with a screwdriver or pinch bar will loosen

rear pinion bearing cup (figures 19-5 and 19-6). Remove

the assembly for easy removal. Pry the differential case and

and record the thickness of the shim pack from behind the

ring gear as straight up as possible using leverage against the

rear pinion bearing cup.

differential case and carrier to prevent damage. Keep the

respective bearing cones if they are not worn or damaged,

and are to be reused.

(13) Place the differential case between the soft jaws

of a vise and remove and discard the drive gear screws. Using

19-2