TM 9-2320-266-34

TA029457

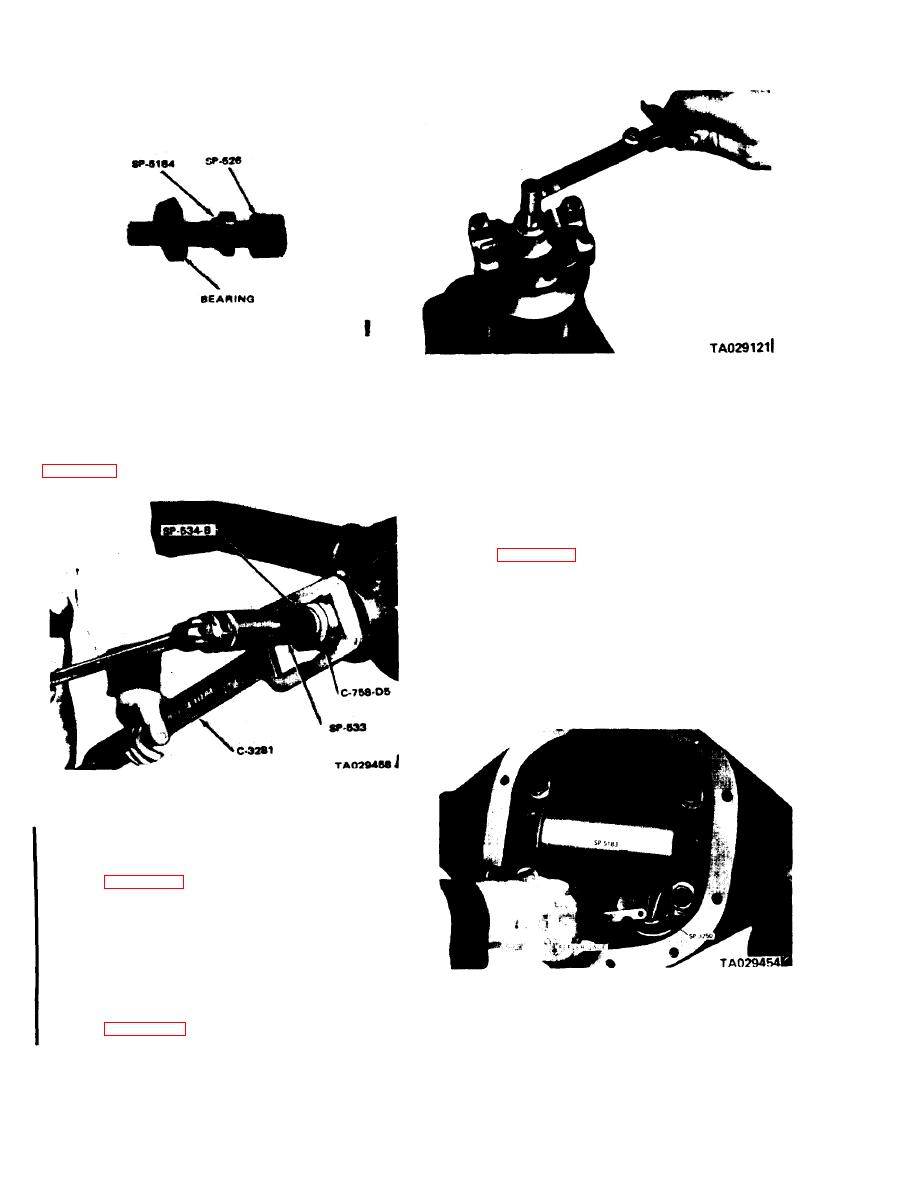

Figure 19-16. Checking Pinion Bearing Preload.

Figure 19-14. Installing the Rear Pinion Bearing Cone.

b. Determining Depth of Mesh and Preload.

(3) Position the tool and rear bearing in the axle

I

housing.

(1) With pinion tool SP-526 in place, attach adapter

SP-3250 with a cap screw and tighten securely.

(4) lnstall the front bearing cone and adapters

SP-534-B, SP-534, and SP-533 on tool SP-526 as shown in

(2) Center adapter SP-5183 in the axle housing.

bolts to 10 ft-lbs.

(4) Use a feeler gage to select the proper thickness

of shims that will fit snugly between adaptors SP-5183 and

SP-3250 (figure 19-17).

NOTE

This measurement will determine the cor-

rect thickness shim pack for installation

behind the rear pinion bearing cup and

the carrier casting.

Figure 19-15. Seating Bearing Cups in Axle Housing.

(5) Lubricate the drive pinion bearing cones.

(6) Hold the compression sleeve with tool C-328 and

tighten the compression nut until the cups are seated.

Refer to figure 19-15, above.

NOTE

Turn the tool several times while tighten-

ing, so the bearing rollers will aline in the

cups and prevent damage.

Figure 19-17. Determining Shim Pack Thickness for

pression nut. Retighten the nut to produce 10-30 in-lbs of

Drive Pinion Depth of Mesh.

preload (figure 19-16).

19-6

Change 1