TM 9-2320-266-34

fit. Position the drive gear on the differential case pilot.

alining the threaded holes of the drive gear with hose in the

differential case flange.

(2) Insert new drive gear screws through the case

flange and into the drive gear. After all capscrews are

properly started, tap the drive gear against the differential

case flange with a non-metallic mallet.

(3) Clamp the unit between the brass jaws of a vise

and alternately tighten each capscrew to 110-115 ft-lbs.

(4) Position each differential bearing cone on the hub

of the differential case (without shims), with the small end

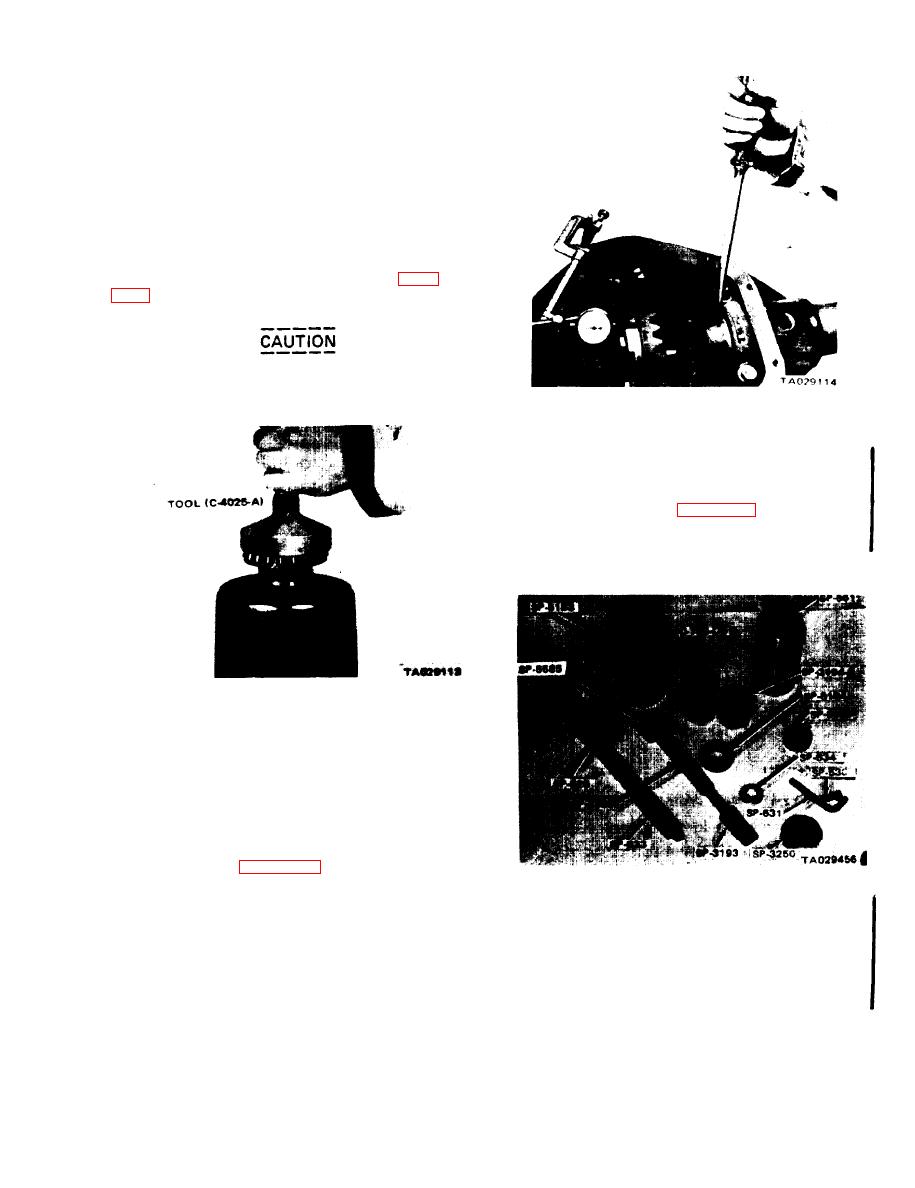

away from the drive gear, using tool C-4025-A (figure

the installing tool.

Never exert pressure against the bearing

cage, since this will damage the bearing

and make it unfit for further use.

Figure 19-12. Determining Shims to Obtain

"O" End Clearance.

19-2. Drive Pinion Depth of Mesh Setting and

Pinion Bearing Preload.

Use tool set C-758-44-60 (figure 19-13) to install the

drive pinion bearing cups, and to determine the pinion

depth of mesh as follows:

Figure 19-11. Installing Differential Bearing Cones.

(5) Position the differential bearing cups on their

respective cones and insert the differential case in the

carrier. Install the bearing caps in their correct positions.

Tighten the bearing cap bolts finger-tight.

(6) Install the dial indicator fixture with the indicator

pointer contacting the back face of the drive gear.

(7) Insert a screwdriver blade between the bearing cup

and housing, and pry the case assembly as far as possible to

one side of housing (figure 19-12). Set the dial indicator at

zero. Using a screwdriver, pry the case to the opposite side

Figure 19-13. Tool Set C-758-44-60.

of the housing and record the reading. This reading indicates

the amount of shims needed to take up the clearance

a. Installing Bearing Cups.

between the differential bearing cups and the case. The

(1) Position the drive pinion cups into the axle

shim pack thickness to be placed on the bearing hub

housing.

between the bearing cone and the differential case will be

(2) Install adapter SP-5184 on shaft SP-526. Then

calculated later in the procedure after you install the drive

install the rear pinion bearing cone (figure 19-14).

pinion and determine depth of mesh setting.

(8) Remove the dial indicator, loosen the bearing cap

bolts and remove the bearing caps. Remove the differential

assembly from the housing.

Change 1

19-5