TM 9-2320-266-34

or damage. Replace all defective parts. Pinion mates must

be replaced in sets.

(5) Inspect the drive gear and pinion for worn or

chipped teeth, or damaged attaching-bolt threads. If re-

placement is necessary, replace both the drive gear and drive

pinion as they are available in matched sets only.

(6) Inspect the universal joint flange for cracks, worn

splines, or a pitted, rough, or corroded oil seal contacting

surface. Repair or replace the universal joint flange as

necessary.

(7) Inspect the drive pinion bearing shim pack for

broken, damaged, or distorted shims. Replace, if necessary,

when you establish the pinion bearing preload.

c. Assembly and lnstallation.

(1) Lubricate all parts with differential lubricant.

Install the differential side gears and thrust washers, the

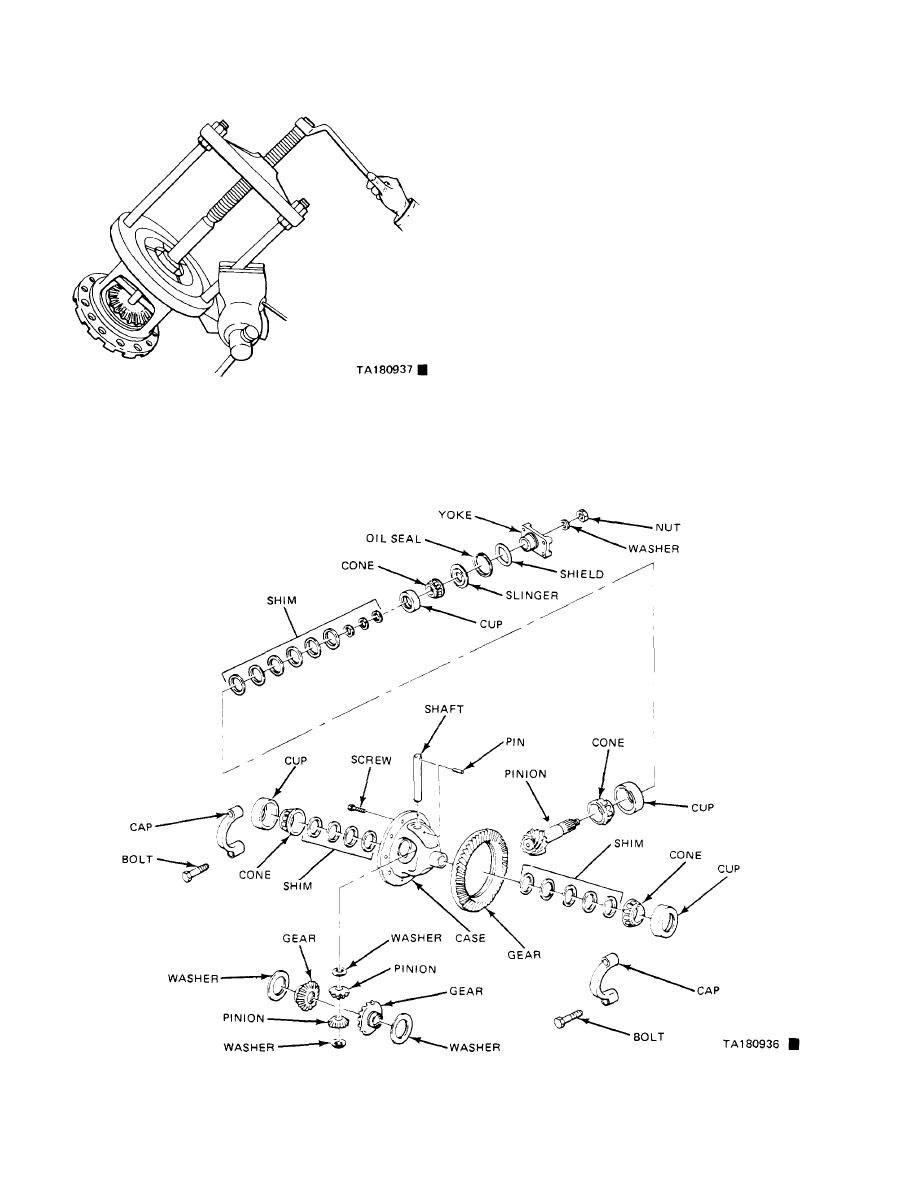

Figure 19-9. Removing Differential Bearings.

pinion mates and thrust washers, and the pinion mate shaft

retainer cages must not be distorted or cracked. When re-

in the differential case. Aline the hole in the shaft with the

hole in the case. Drive in the lockpin. If new gears and

placing the bearings, always replace the cup and cone in a

washers are used, it will not be necessary to check gear

set.

backlash: close manufacturing tolerances insure a correct

(4) Examine the differential pinion mate shaft, the

pinion mates, the side gears, and the thrust washers for wear

Figure 19-10. Differential Disassembled.

19-4

Change 6