TM 9-2320-266-34

Figure 11-5. Measuring Cylinder Walls.

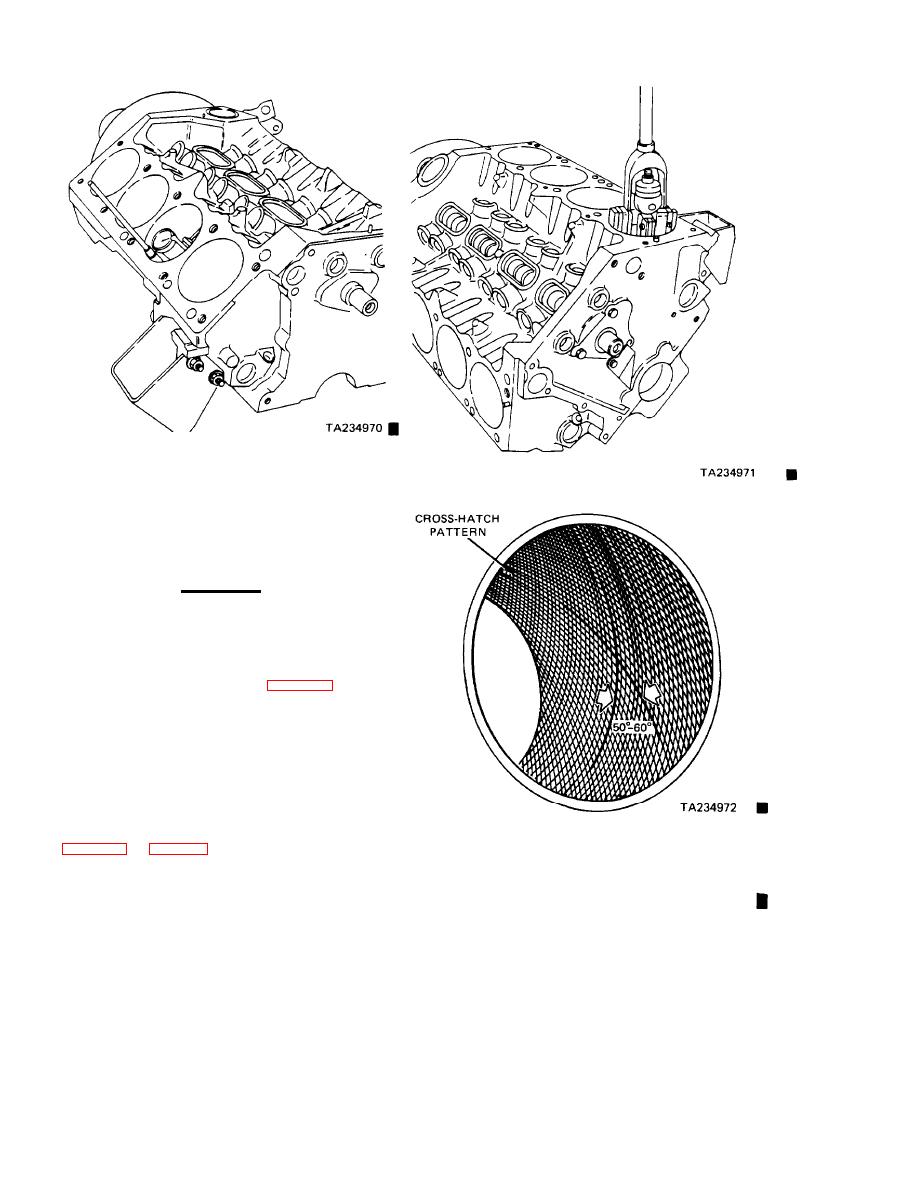

(2) The cylinder walls may be deglazed using a cylin-

der surfacing hone (figure 11.5.1). Use a hone equipped with

Figure 11-5.1. Deglazing Cylinders.

280-grit stones if the cylinder bore is straight and round,

Depending on the bore condition, 20 to 60 strokes will be

sufficient to provide a satisfactory surface. Inspect the

cylinder walls after each 20 strokes. Use a light honing oil.

CAUTION

Do not use engine or transmission oil,

mineral spiris or kerosene.

(3) Honing should he done by moving the hone up

and down fast enough to get a cross hatch pattern. The cross

hatch angle is most satisfactory for proper ring seating when

hone marks intersect at 50-60 degrees (figure 11-6).

(4) After honing. clean the block again to remove all

traces of abrasives. Use a solution of soap and water with a

brush and thoroughly dry the parts. The bore is clean when

a cloth remains clean after wiping it. Oil the bores immedi-

ately after cleaning to prevent rusting.

11-6. Servicing the Crankshaft.

a. General. Crankshafts with one or more undersize con-

necting rods or main bearing journals are steel stamped on the

Figure 11-6. Cross Hatch Pattern.

milled flat on the number eight crankshaft counterweight

b. Measurements. Measure the crankshaft journals for

undersize journals has all rod journals, all main journals, or

taper and out-of-roundness. Maximum allowable out-of.

both, undersize. When replacing a crankshaft, replace

round and maximum allowable taper are both 0.001 inch,

all main and connecting rod bearings with the correct size

Replace crankshafts that do not meet specifications.

new bearings: selective fitting is not required.

Change 7

11-6