TM 9-2320-280-34

17-13. TRANSMISSION ASSEMBLY FROM SUBASSEMBLIES (3L80) (Cont'd)

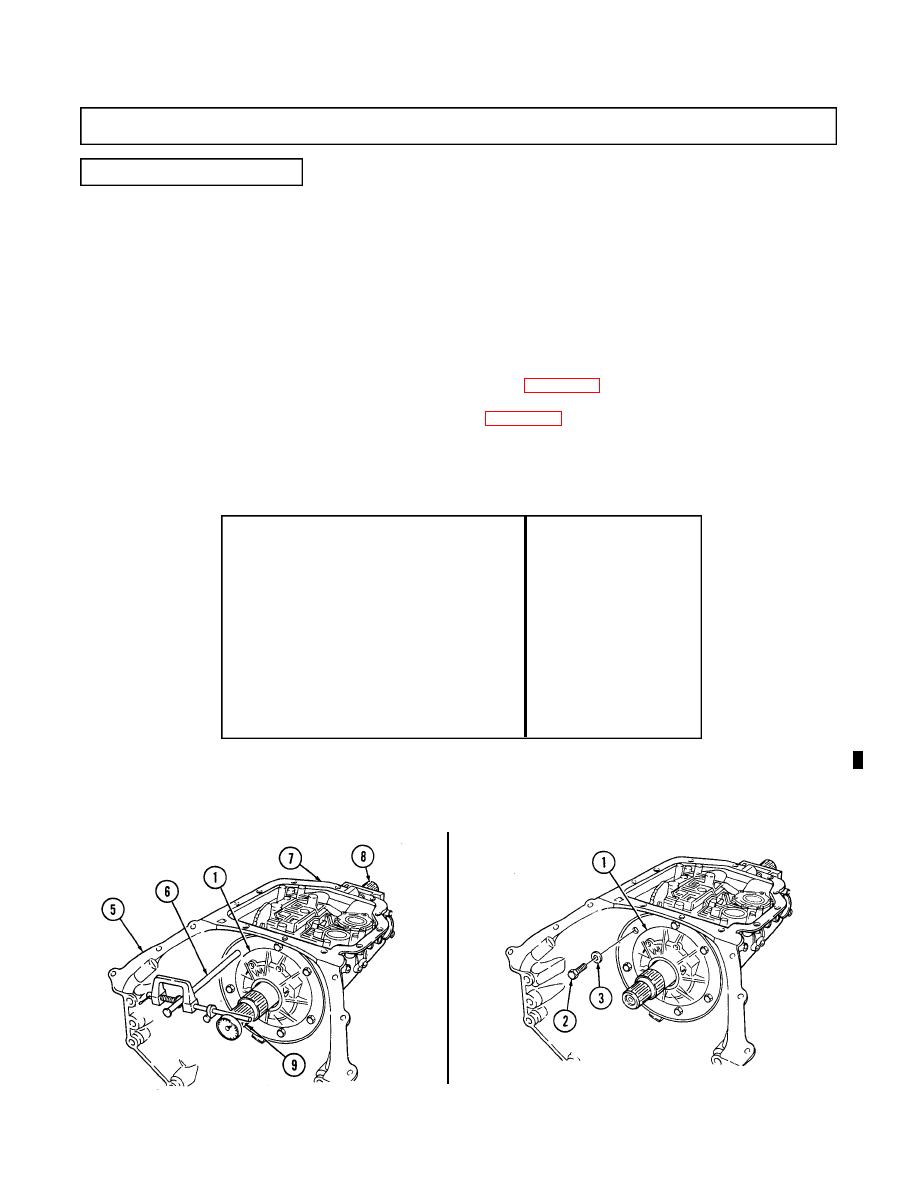

j. Establish Front End Play

1.

Position case (5) so that oil pan sealing surface (7) faces upward.

2.

Install slide hammer bolt (6) into capscrew hole in oil pump (1).

3.

Mount dial indicator on bolt (6) and index indicator to register with end of turbine shaft (9).

4.

Push turbine shaft (9) rearward.

5.

Push output shaft (8) forward, and "zero" dial indicator.

6.

Pull turbine shaft (9) forward, and read dial indicator.

NOTE

Selective washer controlling end play is located between pump

cover and forward clutch housing, refer to para. 17-6. If more or

less washer thickness is required to bring end play within speci-

fications, select proper washer from table 17-3.

An oil soaked washer may tend to discolor. It will be necessary to

measure washer for its actual thickness.

THICKNESS

COLOR

0.060-0.064 in. (1.52-1.63 mm)

Yellow

0.071-0.075 in. (1.80-1.90 mm)

Blue

0.082-0.086 in. (2.08-2.18 mm)

Red

0.093-0.097 in. (2.36-2.46 mm)

Brown

0.104-0.108 in. (2.64-2.74 mm)

Green

0.115-0.119 in. (2.92-3.02 mm)

Black

0.126-0.130 in. (3.20-3.30 mm)

Purple

7.

Resulting travel or end play should be 0.003-0.024 in. (0.076-0.610 mm). If end play is not within

specifications, remove selective washer and install new selective washer of proper thickness.

8.

Remove dial indicator and bolt (6). Install remaining oil pump seal washer (3) and capscrew (2) in

oil pump (1). Tighten capscrew (2) to 16-20 lb-ft (22-27 Nm).

17-55