TM 9-2320-280-34

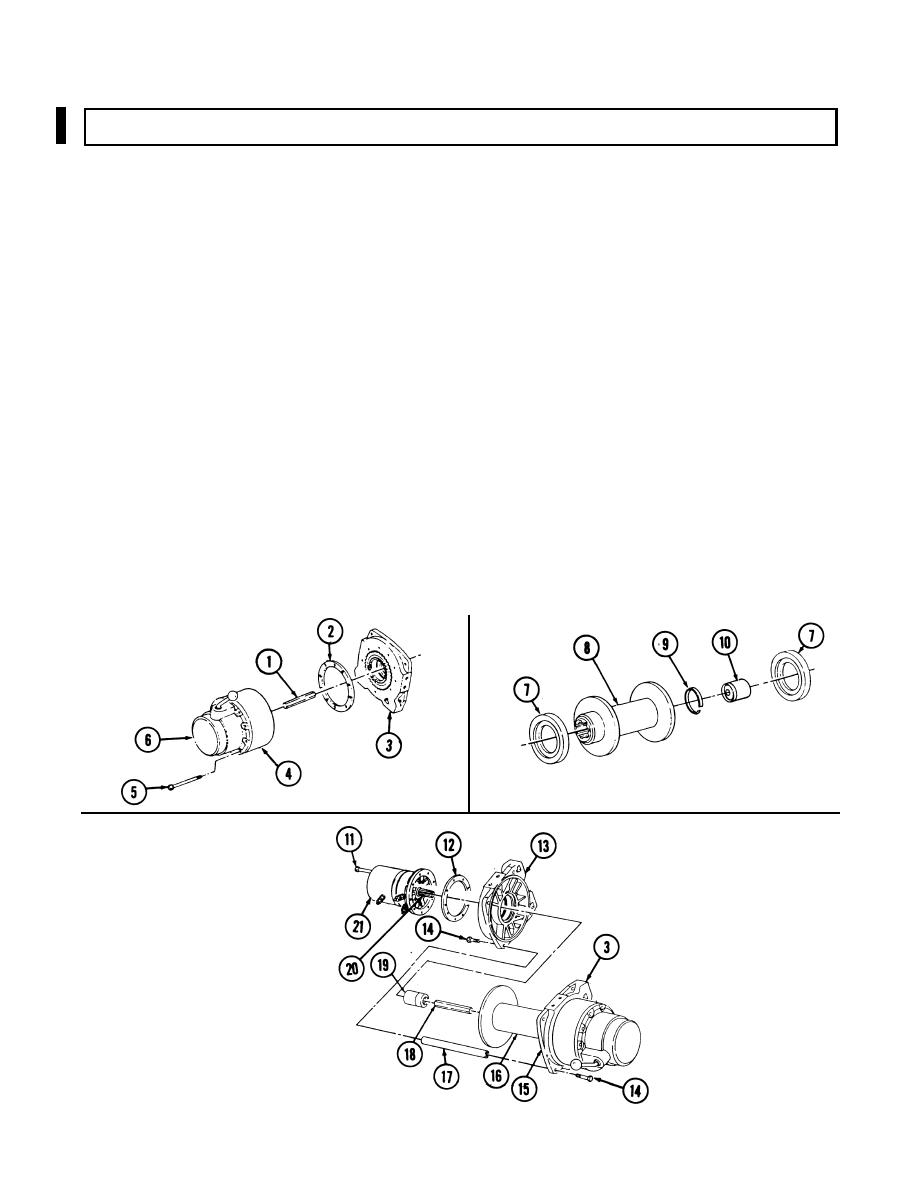

15-4. 9,000 LB. ELECTRIC WINCH REPAIR (Cont'd)

11.

Install gasket (2) on output ring gear (4).

NOTE

Ensure spline on drum support engages in output ring gear.

12.

Install gear end drum support (3) on output ring gear (4).

13.

Install gear housing (6) on gear end drum support (3) with ten hex head screws (5). Tighten hex head

screws (5) to 100 lb-in. (11.3 Nm).

14.

Turn gear housing (6) over with gear end drum support (3) facing up.

15.

Install drive shaft (1) in output ring gear (4).

16.

Apply grease to drum (8) and brake (10) and install thrust washer (9).

17.

With drum horizontal, install brake (10) into drum (8).

18.

Install two nylon thrust washers (7) on drum (8).

19.

Install drum assembly (16) on gear end drum support (3). Rotate drum assembly (16) as needed to

engage drive shaft (1) and brake (10).

20.

Install input shaft (18) and motor shaft coupling (19) in drum assembly (16).

21.

Install motor end drum support (13) on drum assembly (16).

22.

Install gasket (12) on motor (21) and motor end drum support (13) ensuring to engage motor

shaft (20) into motor shaft coupling (19).

23.

Install two hex head screws (11) on motor (21) and motor end drum support (13). Tighten hex head

screws (11) to 35 lb-in. (47 Nm).

24.

Install three tie rods (17) between motor end drum supports (13) and gear end drum support (3) with

six capscrews (14). Tighten capscrews (14) to 18 lb-ft (24 Nm).

Change 2