TM 9-2320-280-34

15-3. 6,000 LB. ELECTRIC WINCH REPAIR (Cont'd)

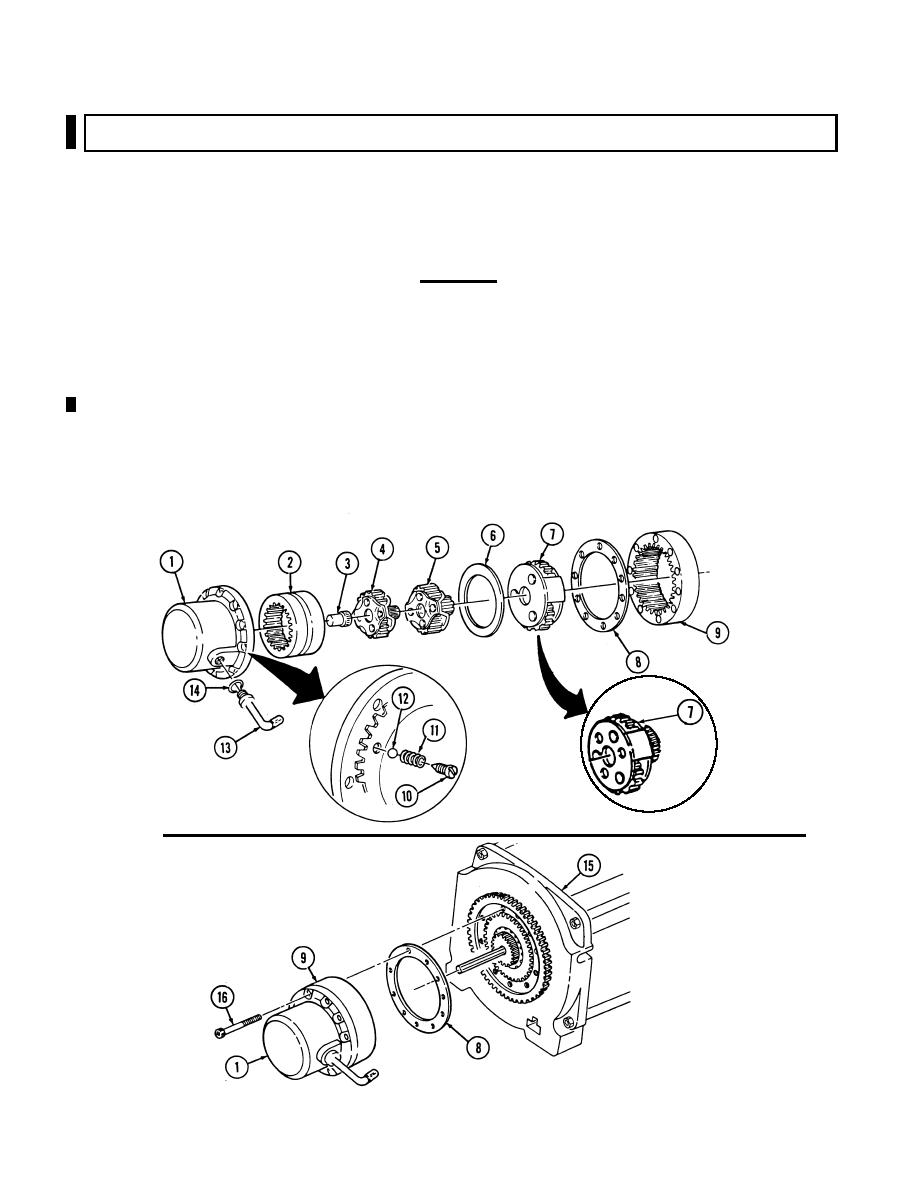

7.

Install clutch ring gear (2) into end housing (1) with pointed ends of gear teeth facing in.

8.

Install O-ring seal (14) on clutch lever (13) and apply aircraft grease to unpainted surfaces of clutch

lever (13).

9.

Align groove in clutch ring gear (2) with hole in end housing (1) and install clutch lever (13) in end

housing (1).

CAUTION

Do not tighten setscrew past flush with housing, or damage to winch

may result.

10.

Install ball (12), spring (11), and setscrew (10) in end housing (1).

11.

Apply aircraft grease to stage one sun gear (3), stage one gear carrier (4), and stage two gear

carrier (5) and install in end housing (1).

12.

Apply aircraft grease to thrust washer bearing (6) and stage three gear carrier (7) and install in

end housing (1).

13.

Install gasket (8) and ring gear (9) on end housing (1).

14.

Install end housing (1), ring gear (9), and gasket (8) on drum support (15), ensure to align reference

marks and secure with ten socket-head screws (16). Using hex-head driver, tighten screws (16) to

35 lb-in. (4 Nm).

NEW CONFIGURATION

15-12

Change 2