TM 9-2320-266-34

Table 18-3. Thrust Washer Wear Limits

Reaction shaft support to

front clutch retainer. . . . . . . . . . . . . . . . . . . . . . #1 Selective

0.061" to 0.063"

Natural

0.084" to 0.086" Red

0.102" to 0.104"

Yellow

Front clutch to rear clutch. . . . . . .

#2 0.061" to 0.063"

Input shaft to output shaft. . . . . . .

#3 0.063" to 0.064"

Front annulus support to

front carrier. . . . . . . . . . . . . .

#4 0.060" to 0.062"

Front annulus support to

driving shell. . . . . . . . . . . . . . #5 0.060" to 0.062"

Driving shell thrust plate. . . . . . .

#6 0.034" to 0.036"

Rear carrier to driving shell. . . . . .

#7 0.060" to 0.062"

Rear annulus thrust plate. . . . . . . . #8 0.034" to 0.036"

the shaft and in the annulus gear, making sure the teeth are

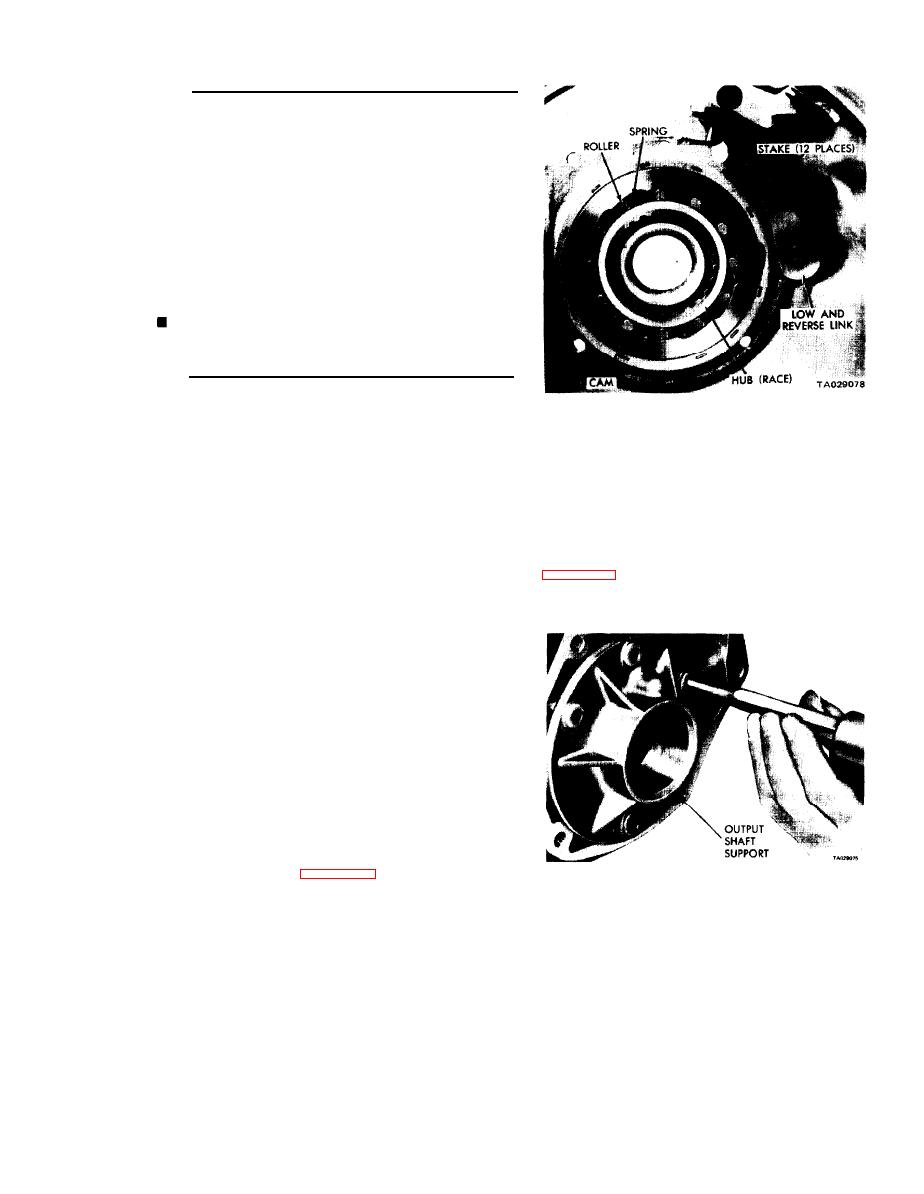

Figure 18-24. Overrunning Clutch, Low and

over the shaft splines.

Reverse Band Link.

(2) Position the rear planetary gear assembly in the

b. Replacing the Overrunning Clutch Cam. If the over-

rear annulus gear. Place the thrust washer on the front side

running clutch cam and/or roller spring retainer are found

of the planetary gear assembly.

damagcd, replace the cam and spring retainer as follows.

(3) Install a snap ring in the front groove of the sun

gear (long end of the gear). Insert the sun gear through the

(1) Remove the set screw from the case below the

front side of the driving shell. lnstall the rear steel washer

clutch cam.

and snap ring.

(2) Remove the four bolts securing the output shaft

(4) Carefully slide the driving shell and sun gear

support to the rear of the transmission case. Insert a punch

assembly onto the output shaft, engaging the sun gear teeth

through the bolt holes and drive the cam from the case

with the rear planetary pinion teeth. Place the thrust washer

inside the front driving shell.

another so the cam wiII be driven evenly from the case.

(5) Place a thrust washer on the rear hub of the front

planetary gear set. Slide the assembly into the front annulus

gear.

(6) Carefully work the front planetary and annulus

gear assembly on the output shaft, meshing the planetary

pinions with the sun gear teeth.

(7) With all components properly positioned, install

the selective snap ring on the front end of the output shaft.

Remeasure the end play of the assembly.

NOTE

The clearance can be adjusted by using

snap rings of various thicknesses. They

are available in 0.048, 0.055, and 0.062

inch thicknesses.

18-12. Overrunning Clutch.

Figure 18-25. Removing Overrunning Clutch Cam.

for smooth, round surfaces. They must be free of flat spots

and chipped edges. Inspect the roller contacting surfaces in

the cam and race for damage. lnspect the roller springs for

distortion, wear, or other damage. Inspect the cam setscrew

for tightness. If loose, tighten and restake the case around

the screw.

Change 2

18-13