TM 9-2320-266-34

c. Rear Servo "Apply" Pressure.

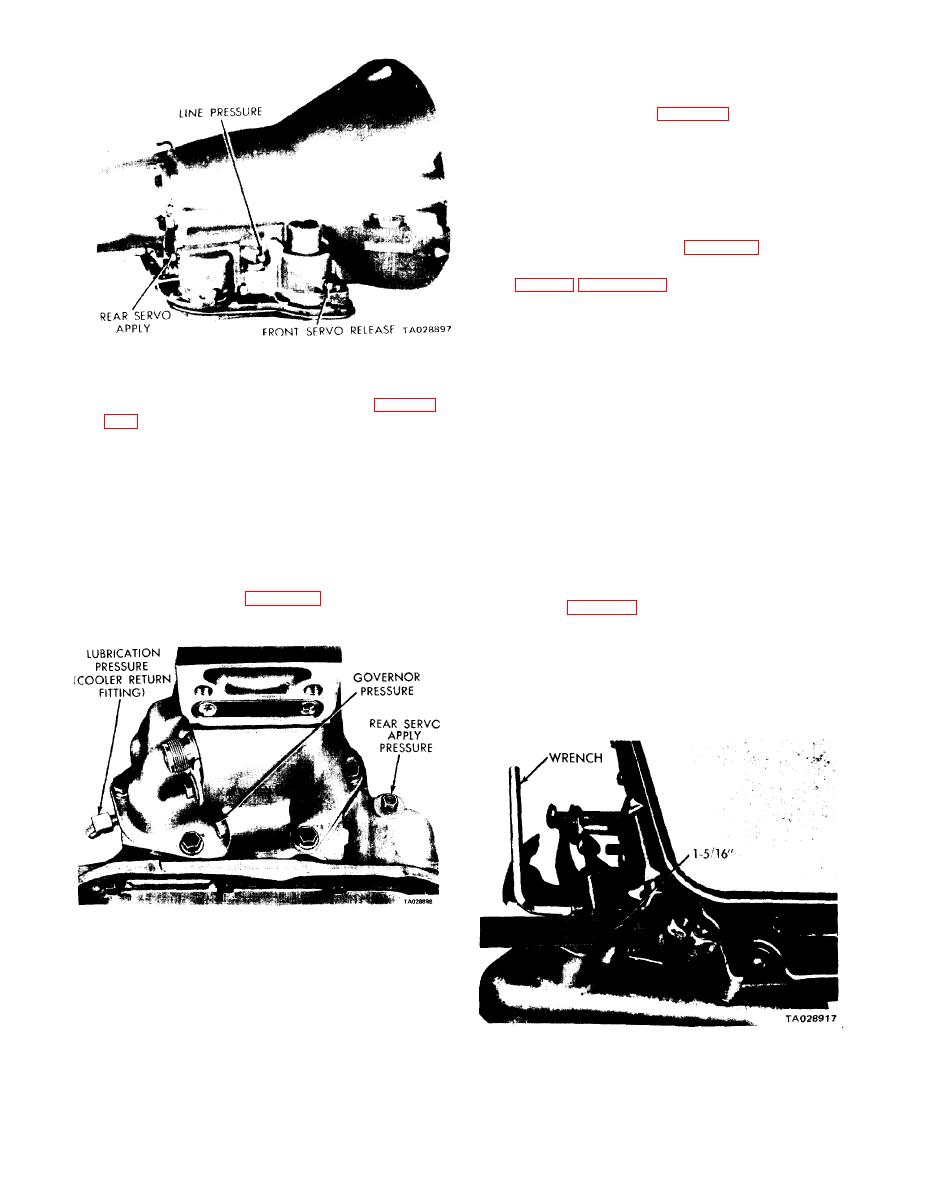

take-oft' point at the rear servo (figure 4-31).

(2) With the transmission control in the "R" position

and the engine speed set at 1,600 rpm, the reverse servo

"apply" pressure should be 230 to 260 psi.

d. Governor Pressure.

pressure take-off point, located at the lower left side of the

extension near the mounting flange (figure 4-31).

(2) Governor pressures should fall within the limits

given in table 4-2 (paragraph 4-3). If they are incorrect at

the given speeds, the governor valve and/or weights are prob-

ably sticking.

e. Throttle Pressure. There is no throttle pressure test.

Incorrect throttle pressure should only be suspected if part-

throttle upshift speeds are either delayed or occur too early

Figure 4-30. Pressure Test Locations (Right Side of Case).

in relation to vehicle speeds. Engine runaway on either up.

shifts or downshifts can also indicate incorrect (low) throttle

graph 4-15, below. If front servo release pressures are less

pressure setting. Never adjust the throttle pressure until the

than pressures specified and line pressures are within limits,

transmission throttle linkage adjustment has been verified to

there is excessive leakage in the front clutch and/or front

be correct.

servo circuits. Always inspect the external transmission

4-15. Hydraulic Control Pressure Adjustments.

throttle lever for looseness on the valve body shaft when

making the pressure tests.

a. Line Pressure.

incorrect throttle pressure setting

An

will cause incorrect line pressure readings even though the

b. Fluid Pressure. Test fluid pressure at the same time

line pressure adjustment is correct. Always inspect and

that you test line pressure and front servo release pressure.

correct the throttle pressure adjustment before adjusting

(1) Install a "T" fitting between the cooler return line

the line pressure. The approximate adjustment is 1-5/16

fitting and the fitting hole in the transmission case at the rear

inches, measured from the valve body to the inner edge of

left side of the transmission (figure 4-31). Connect a 100

the adjusting nut (figure 4-32). However, due to manufac-

psi pressure gage to the "T" fitting.

turing tolerances, the adjustment can be varied to obtain the

specified line pressure. The adjusting screw may be turned

with an allen wrench. One complete turn of the adjusting

screw changes the closed throttle line pressure approximately

1-2/3 psi. Turning the adjusting screw counterclockwise in-

creases the pressure, and clockwise decreases pressure.

Figure 4-31. Pressure Test Locations (Rear End of Case).

(2) The fluid pressure should be 5-15 psi at 1,000

engine rpm, with the throttle closed and the transmission in

direct drive. It will be approximately double when the throt-

tle is opened to maximum line pressure.

Figure 4-32. Line Pressure Adjustment.

4-22