TM 9-2320-289-34

4-3.

ALTERNATOR TESTING AND REPAIR (M1010) (Con’t).

10.

11,

NOTE

If 1 rectifier was determined to be good in step 8, but other rectifier had to

be replaced, terminal loops at each lead (22) will have to be cut to

separate positive rectifier (28) from negative rectifier (20). Ensure that

leads are tagged for assembly if this is done,

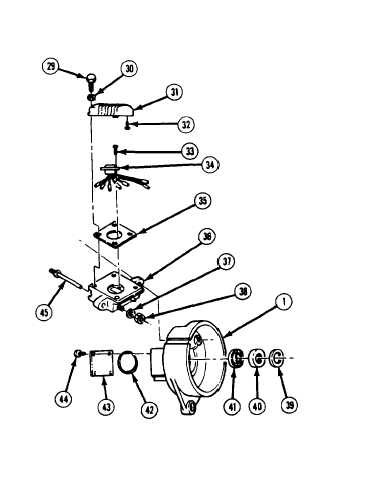

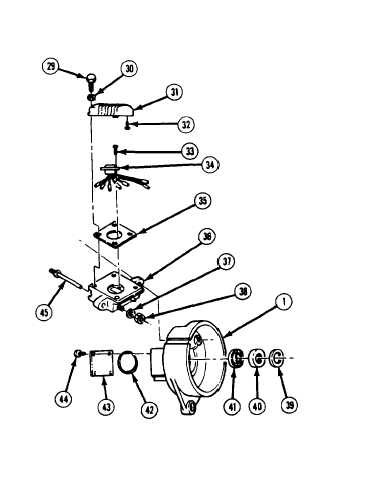

Remove positive rectifier (28) and negative rectifier (20) from slipring end housing (1).

Remove 2 upper housing bushings (18), output terminal bushings (19), and lower housing

bushings (27) from slipring end housing,

Tag connector (34) leads and

disconnect from AC “terminal studs

(45) and regulator holder (44).

CAUTION

DO NOT pry on regulator (31) to

remove.

Failure to follow this

caution may result in damage to

regulator.

12.

Remove 4 screws (29), Iockwashers

(30), and regulator (31 ). Remove

and discard gasket (35). Discard

Iockwashers.

CAUTION

Before

changing

p o s i t i o n of

adjustment screw (32), ensure

that “HI” position hole in regulator

(31)

is

clear of obstructions.

Failure to follow this caution may

result in damage to regulator.

13.

14.

15.

16.

Ensure that adjustment screw (32) is

in “HI” position if regulator (31) will

not be replaced.

Remove 3 nuts (38), washers (37),

and AC terminal studs (45).

NOTE

Perform step 15 only if brush holder adapter was removed.

Pull connector (34) lead through access hole and grommet in slipring end housing (1).

Remove regulator holder (36). Remove 2 screws (33) and connector.

Remove 4 screws (44), cover plate (43), and “ O“ ring (42) from slipring end housing (1).

Remove inner seal (39). Insert punch in pilot hole on cover plate side of slipring end housing.

Drive out slipring bearing (40) and outer seal (41). Discard seals and “O“ ring.

TA50788

4-17