TM 9-2320-280-34

6-5. 200 AMPERE ALTERNATOR (12338796-1) TESTING AND REPAIR (Cont'd)

9.

Regulator Bypass Test.

NOTE

Perform this test only when instructed from tables 6-A.7 and 6-B.

(a) Prepare alternator as in full load test.

NOTE

Use jumper wire rated for 15 amps.

(b) Disconnect alternator connector from regulator. With alternator spinning, use jumper wire and

short pin A of connector to ground momentarily. Record results.

(c) Amperage should rise within 10% of rated output with jumper wire connected and fall with

jumper disconnected. Refer to Table 6-C, Regulator Bypass Test, for diagnosis.

10.

Turn test stand master power switch and load switch to OFF.

11.

Disconnect jumper wires from terminals on test stand and alternator.

12.

Remove "V" belt from test stand pulley and alternator pulley. Remove alternator from test stand.

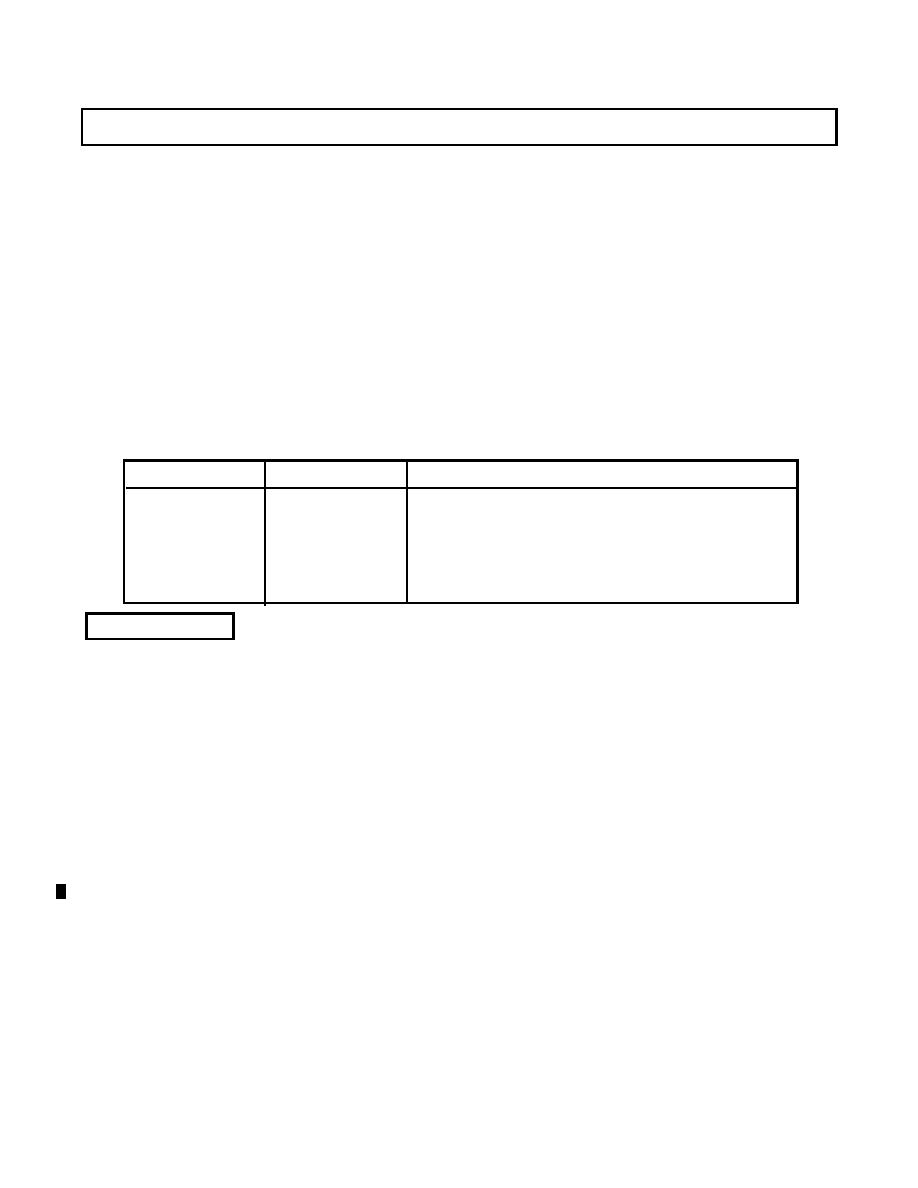

Table 6-C. Regulator Bypass Test.

CONNECT

DISCONNECT

DIAGNOSIS

AMPS RISE

AMPS FALL

Alternator OK. See note. Replace regulator only if

low AMPS (80-119)/low VOLTS (21-25) are indicated

in table 6-A.7 and/or table 6-B.

NO CHANGE

NO CHANGE

Alternator must be repaired. Refer to Static Testing.

b. Disassembly

NOTE

Complete alternator disassembly is not required for static testing.

1.

Remove voltage regulator (TM 9-2320-280-20).

1.1.

Install core and shaft assembly (11) in soft-jawed vise and remove locknut (6), washer (5), and

fan (4) from core and shaft assembly (11). Discard locknut (6).

2.

Remove bearing bushing (3) from core and shaft assembly (11).

3.

Remove three screws (20), lockwashers (21), and plate cover (19) from front housing (17). Discard

lockwashers (21).

4.

Scribe alignment marks on front housing (17), stator (9), and end housing (2).

5.

Remove nine locknuts (7) from end housing (2) and stator (9). Discard locknuts (7).

6.

Use puller to remove end housing (2) from stator (9).

7.

Remove six nuts (1) from rear rotor (24) on core and shaft assembly (11).

8.

Use three 10-32 x 2-in. long machine screws as jacks in threaded holes on end plate of rear

rotor (24). Gradually tighten screws to remove rear rotor (24) from core and shaft assembly (11).

Remove rear rotor (24) and screws.

NOTE

Prior to removal, tag leads for installation.

9.

Remove eight nuts (18) and disconnect two field and six phase leads (8) from diodes in front

housing (17).

10.

Remove nine locknuts (22) from front housing (17) and stator (9). Discard locknuts (22).

11.

Remove front housing (17) from stator (9) by tapping lightly with a soft-faced mallet.

Change 2