TM 9-2320-246-34

(d) The flame detector switch must transfer with-

in 150 seconds from the moment the heater control switch

was turned on.

NOTE

Ignition may be inaudible. If so, transfer

time of flame detector switch will be used

as the limiting factor for test.

(e) Immediately after the flame detector switch

transfers, turn the HI-LO switch to HI and note current

draw. Draw must not exceed 6.3 amperes.

NOTE

Add 3.5 amperes to maximum current

draw if test is conducted at a temper-

ature that will maintain the fuel valve

thermostat in a closed position.

(9) Observe high heat fuel flow on the flowmeter.

Flow must be more than 0.027 lb/rein., but less than 0.033

lb/rein.

(10) If fuel rates for high heat are not within limits,

turn adjusting screw of the fuel control valve clockwise to

increase fuel flow, or counterclockwise to decrease flow

and retest. If, after adjusting fuel flow for high heat, it is

found that low heat flow is not within limits, it is an indi-

cation that one of the metering holes in the orifice plate is

clogged. Replace fuel control valve assembly.

(11) While heater is burning on high heat, block off

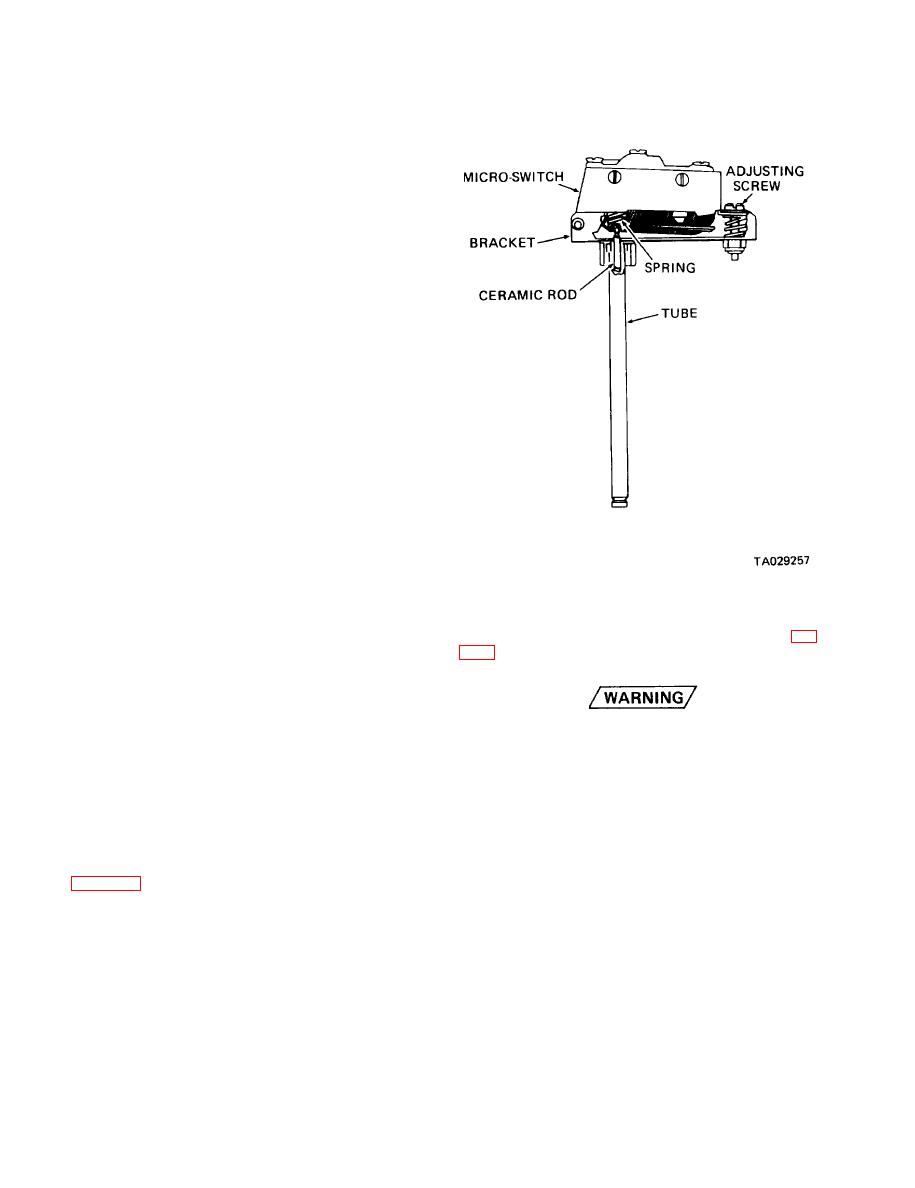

Figure 24-6. Flame Detector Switch.

all flow of ventilating air by covering the heater outlet with

cardboard or sheet metal. The overheat switch must open

and shut off fuel flow in more than 15 seconds, but less

than 30 seconds from the moment air flow was shut off.

24-3). Replaced adapter is retained to heater with three

Replace the overheat switch if not within limits and retest.

screws.

(12) After heater has been burning on high heat for

at least 1 minute, turn heater control switch off. Fuel

flow must drop to zero for more than 1 minute, but less

To prevent escape of poisonous exhaust

than 3-1/2 minutes, and must then automatically stop. Re-

gases, be certain to install exhaust tube

set, or replace, the flame detector switch if not within lim-

retaining clamps securely when perform-

its and retest.

ing the following steps.

(13) To time the blower, mark the combustion air

blower fan with chalk. Start the heater and time the fan

(3) Position heater on base plate. For the M880 or

with a suitable tachometer. Blower speed must be within

M882 vehicle, secure heater to exhaust tube by tightening

the limits of 6,800 to 7,800 rpm with restriction on the

clamp. For the M886 ambulance, secure heater to flexible

heater outlet and an applied voltage of 24 volts.

exhaust tube and secure with clamp.

(4) Secure heater to base plate with two adjustable

h. Adjusting Flame Detector Switch. Refer to

hose clamps. For the M880 or M882, secure hose duct to

adapter with clamp.

(z) Back off on the adjusting screw until the micro-

(5) Connect power cable connector to heater.

switch clicks (or one full turn).

(6) Install adapter and connect fuel line to heater.

(2) Turn adjusting screw slowly in until the switch

clicks, then turn exactly 3/4 turn past the click point.

(7) Install heater guard.

(3) Cement adjusting screw in place with Glyptal

(8) For the M880 or M882, install guard. For the

varnish or suitable substitute.

M886 ambulance, install adapter and cover plate.

i. Installation.

(9) Connect battery ground cable,

(1) Position adapter on heater hot air outlet and

(10) Turn on shutoff cock.

secure with four screws and washers.

24-14

Change 5