TM 9-2320-266-34

(4) Use a feeler gage to select the proper thickness of

shims that will fit snugly between adapters SP-561 and

SP-3250 (figure 20-16).

NOTE

This measurement will determine the cor-

rect thickness shim pack for installation

behind the rear pinion bearing cup and the

carrier casting.

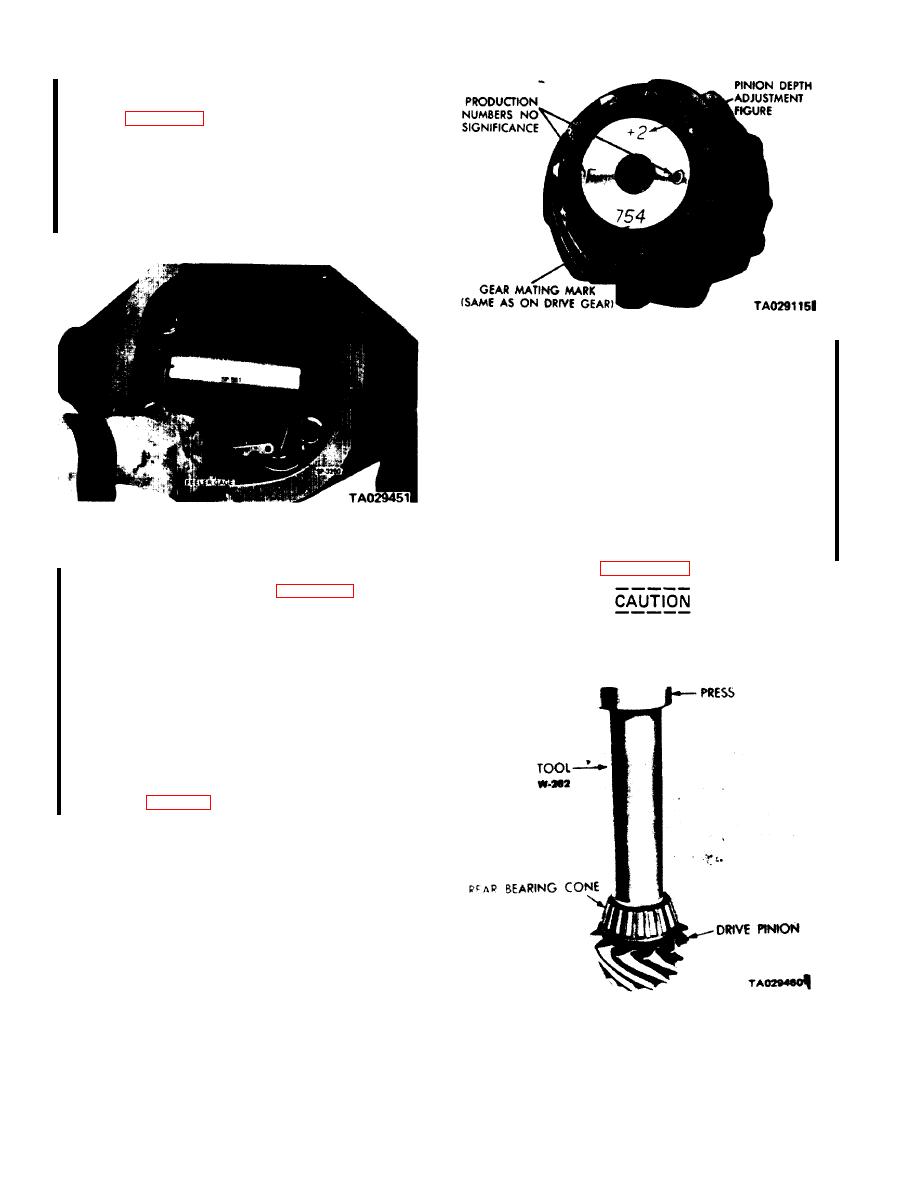

Figure 20-17. Drive Pinion Markings.

(6) If the marking is negative, add the correct amount

of shims. If the marking is positive, subtract the correct

amount of shims. Shims are available in 0.003, 0.005, and

0.010 inch thicknesses.

(7) Remove the tool and adapters from the axle

housing.

(8) Remove the rear pinion bearing cup and install

the correct shim pack.

(9) Reinstall the rear bearing cup as described in a,

above.

Figure 20-16. Determining Shim Pack Thickness for Drive

Pinion Depth of Mesh.

(10) Lubricate the cone, and install it on the pinion

shaft using tool W-262 (figure 20-17.1 ).

(5) To select a shim pack, read the markings on the

end of the pinion head as shown in figure 20-17. One num-

ber is found on both the drive pinion and the ring, which

indicates a matched gear set. Directly opposite this number

To prevent damage to the bearing, do not

will be one with a "+" or "-" before it, or the number will

strike the bearing cage during installation.

be "0." This number must be positively identified before

continuing the assembly procedure. Midway between the

two sets of numbers described above are numbers and letters

which are etched for manufacturing purposes only. But as

one of these numbers may be "0," it might be confused

with the number needed for the assembly procedure. A

rule to follow would be to first examine the shaft end for a

positive or negative number. If a positive or negative num-

ber is not etched on the pinion head, then the number will

be zero (see table 19-1).

Figure 20-17.1. Installing the Front Pinion Bearing Cone.

20-6

Change 1