TM 9-2320-266-34

(8) Install spreader tool W-129-A and a dial indicator

and spread the earner 0.015 to 0.020 inch. Remove the

bearing caps and lift the differential assembly from thc

housing. Then remove the spreader.

20-2. Drive Pinion Depth of Mesh Setting and

Pinion Bearing Preload.

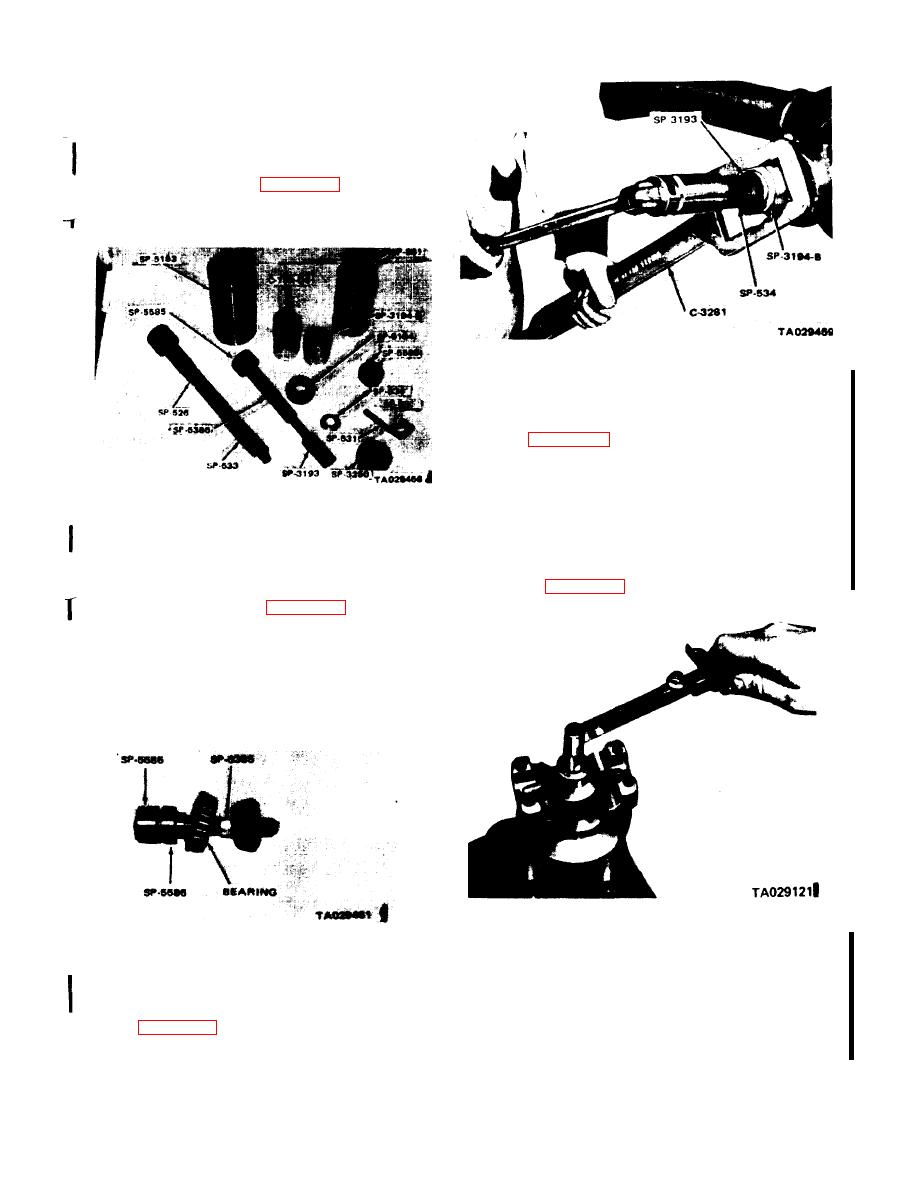

Use tool set C-758-44-60 (figure 20-12) to install the

drive pinion bearing cups, and to determine the pinion

depth of mesh as follows:

Figure 20-14. Seating Bearing Cups in Axle Housing.

(5) Lubricate the drive pinion bearing cones.

(6) Hold the compression sleeve with tool C-3281.

and tighten the compression nut until the cups are seated.

Refer to figure 20-14, above.

NOTE

Turn the tool several times while tight-

Figure 20-12. Tool Set C-758-44-60.

ening, so the bearing rollers will aline in

a. Installing Bearing Cups.

the cups and prevent damage.

(1) Position the drive pinion cups into the axle

housing.

pression nut. Retighten the nut to produce 10-30 in-lbs

of preload (figure 20-15).

(2) Install adapter SP-5586 on shaft SP-5585. Then

install the front bearing cone (figure 20-13).

Figure 20-15. Checking Pinion Bearing Preload.

Figure 20-13. Installing the Front Bearing Cone.

b. Determining Depth of Mesh and Preload.

(1) With pinion tool SP-5385 in place, attach adapter

(3) Position the tool in the axle housing.

SP-3250 with a cap screw and tighten securely.

(4) Install adapter SP-5585, the front bearing cone,

(2) Center adapter SP-561 in the axle housing.

and adapters SP-3194-B, SP-534, and SP-3193 on tool

SP-5385 (figure 20-14).

bolts to 10 ft-lbs.

Change 1

20-5