TM 9-2320-266-34

(6) Flush and blow out the oil cooler and its lines

(paragraph 184).

18-4. Flushing Oil Cooler and Tubas.

a. General. When a transmission failure has cuntaminated

the fluid, flush the oil cooler to insure that metal particles or

sludged oil are not later transferred back into the recondi-

tioned transmission.

b. Procedure.

(1) Place a length of hose over the end of the back oil

cooler tube. lnsert the other end securely into a waste oil

container.

(3) Pump approximately 1 pint of automatic trans-

mission fluid into the forward oil cooler tube.

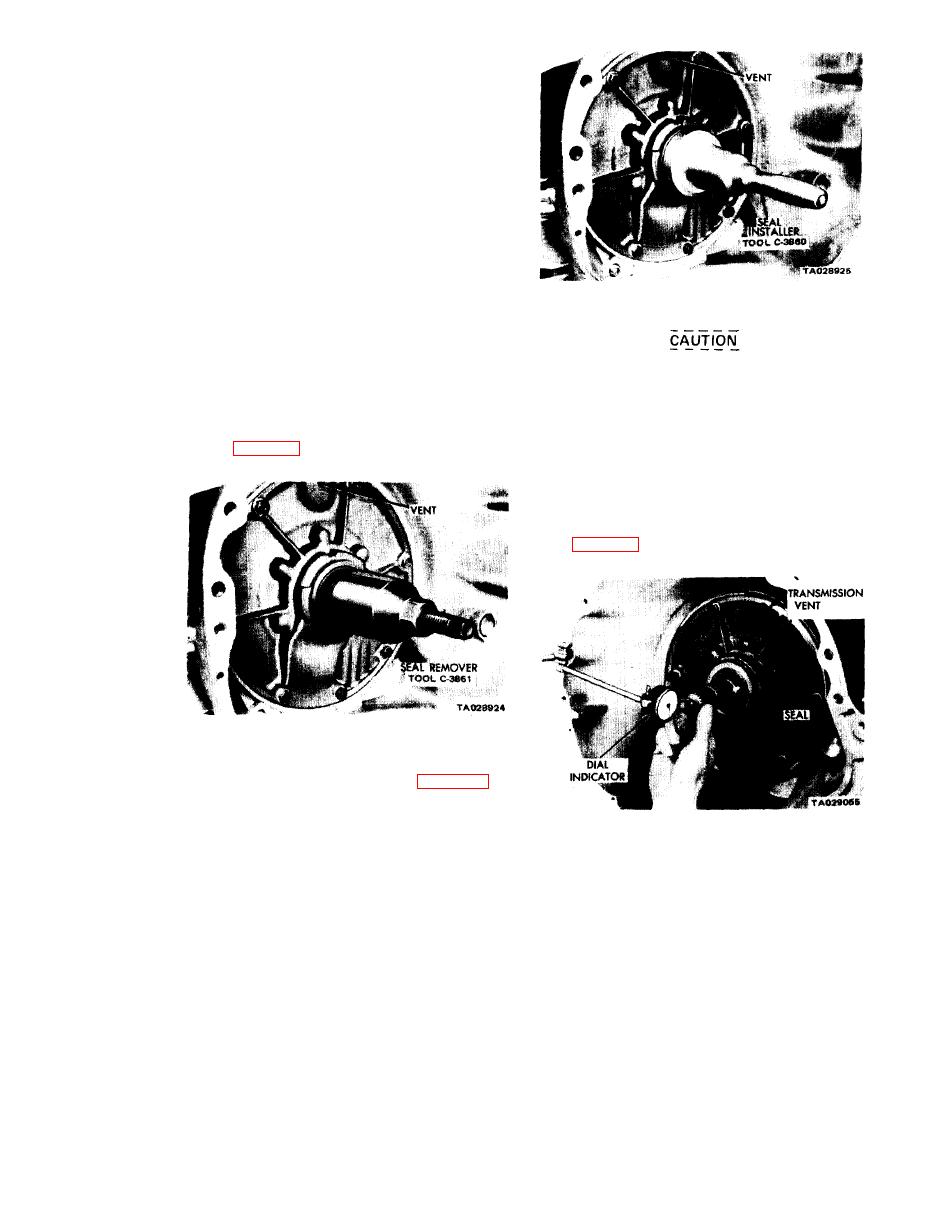

Figure 18-3. Installing Pump Oil Seal.

(4) Remove the hose

18-5. Replacing the Pump Oil Seal.

DO NOT wipe parts dry with shop towels

a. General. The transmission pump oil seal can be re-

placed without removing the pump and reaction shaft sup-

(2) Be extremely careful when handling parts. All

port assembly from the transmission case.

transmission mating surfaces tire accurately machined: care-

b. procedure,

less handling will cause nicks and burrs.

(1) Screw a seal remover (tool C-3861) into the seal as

b. Input Shaft End Play. Measuring input shaft end play

shown in figure 18-2.

before disassembly will usually indicate when a thrust washer

change is required (except when major parts are replaced).

The thrust washer is located between the reaction shaft sup-

port and the front clutch retainer.

(1) Attach a dial indicator to the transmission bell

housing with the plunger seated against the end of the input

shaft (figure 18-4).

Figure 18-2. Removing Pump Oil Seal.

(2) Place a new seal in the opening of the pump hous-

ing with its lip facing inward. Use tool C-3860 to drive the

seal into the housing until the bottoms (figure 18-3).

18-6. Disassembling the Transmission.

a. Removing Subassemblies. Before removing any trans-

Figure 18-4. Measuring Input Shaft End Play.

mission subassemblies, plug all openings and thoroughly clean

(2) Move the input shaft in and out to obtain end play

the unit's exterior. Steam cleaning is preferred. Cleanliness

reading. End play specifications are 0.036 to 0.084 inch for

through the entire disassembly and assembly procedures is

transmissions.

extremely important. Follow these rules:

(3) Record the indicator reading for reference when

(1) When distrssembling, wash each part in a suitable

reassembling the transmission.

solvent and then dry it with compressed air.

18-3