TM 9-2320-266-34

(a) Loosen the adjuster locknut two turns.

7-13. Adjustments.

(b) Back out the adjuster plug one turn to

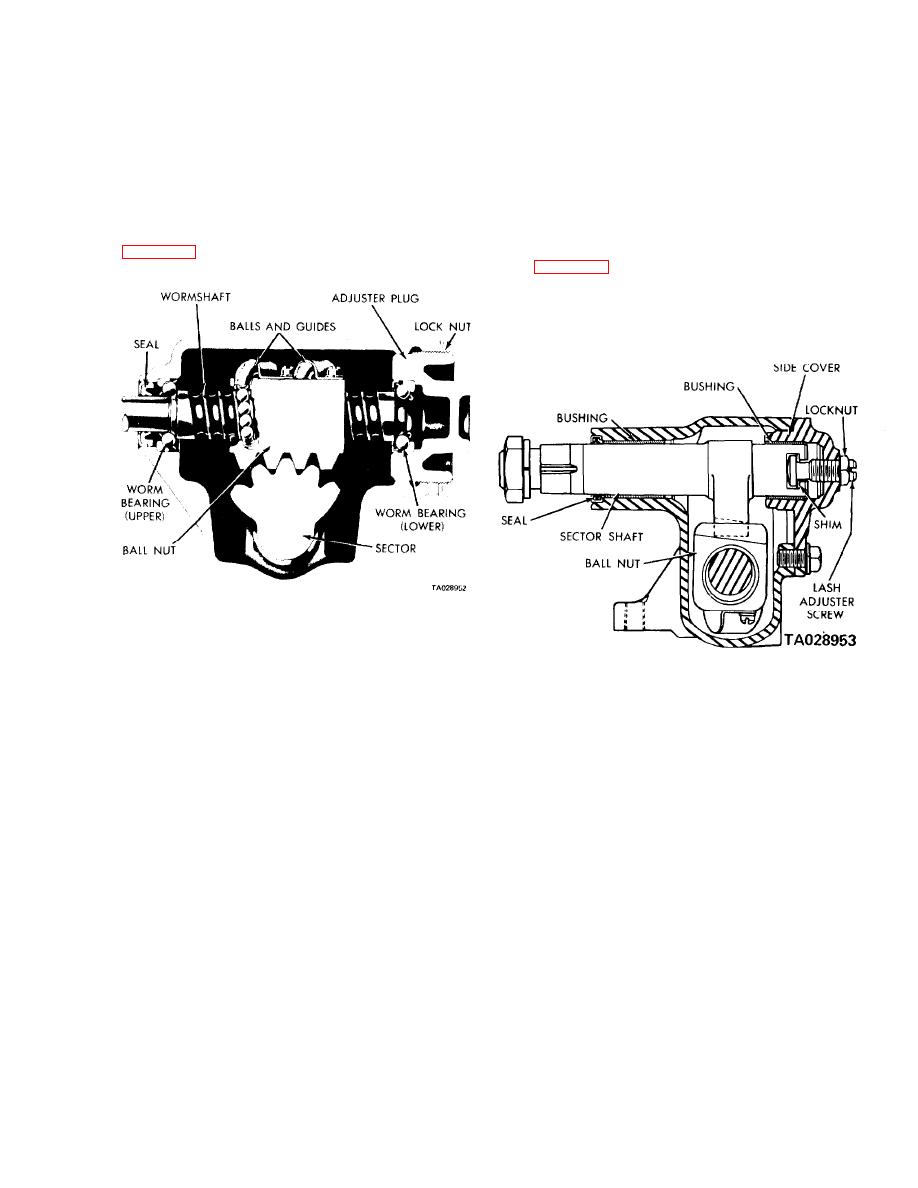

Two adjustments are provided in the steering gear: the

completely relieve worm bearing preload.

worm bearing preload adjustment, and the ball nut gear

mesh lash adjustment. Before the correct adjustment can

(c) Turn the adjuster plug clockwise until the

be made at the ball nut rack and the sector gear, it must be

torque reading is within specification (4-6 in-lbs).

determined that the worm thrust bearing adjuster plug is

(d) While keeping the adjuster plug from turning,

set for the proper worm bearing preload. The adjuster

tighten the locknut securely. Then retest torque.

threads into the housing at the lower end of the wormshaft.

(8) When worm bearing preload is 4-6 in-lbs, adjust

a. Worm Bearing Preload. Preload is determined by the

the ball nut rack and sector mesh (b, below).

pressure exerted against the wormshaft by the adjuster plug.

b. Ball Nut Rack and Sector Mesh. The lash adjuster

See figure 7-13.

screw (figure 7-14), located in the housing cover, raises or

lowers the sector shaft to provide proper mesh between

the tapered sector gear teeth and the tapered ball nut teeth.

Adjust this mesh only after establishing the proper worm

bearing preload (a, above).

Figure 7-13. Steering Gear.

(1) Turn the front wheels to the straight-ahead

position.

Figure 7-14. Steering Gear (Including Lash Adjuster Screw).

(2) Disconnect and remove the steering gear arm

from the sector shaft.

(1) Turn the steering wheel from one stop to the

other, keeping careful track of the number of turns. Turn

(3) Remove the horn pad to expose the steering

the steering wheel back exactly halfway to the center

shaft nut.

position.

(4) Turn the steering wheel all the way to the right,

(2) Turn the steering wheel about one-quarter turn

then back it off slightly to relieve any binding.

away from the center ("high spot") position. Place an inch-

(5) Place an inch-pound torque wrench on the

pound torque wrench on the steering shaft nut.

steering shaft nut.

(3) Use the wrench to rotate the steering wheel

(6) Use the wrench to rotate the steering shaft

through the center ("high spot") position, while reading

toward the left, while reading the torque. The torque

the torque. This reading is the total of the worm shaft

required to keep the steering shaft nut moving should be

bearing preload and the "high spot" sector gear mesh load.

from 4 to 6 in-lbs.

The torque required to rotate through the center position

should be 14 in-lbs.

NOTE

There is a "high spot" in the center of the

sector gear mesh as follows:

sector gear to increase turning torque when

(a) Loosen the lash adjuster screw locknut and

the wheels point straight ahead. Always

turn out the adjuster screw enough to take out all lash

test preload torque with the steering wheel

between the ball nut rack and the sector gear teeth.

turned well away from center.

(b) Adjust the lash adjuster screw to obtain a 14

in-lbs torque wrench reading through the center ("high

lbs, adjust bearing preload as follows:

7-7

441-399 0 - 84 - 7