TM 9-2320-289-34

6-17.

REAR AXLE DRIVE PINION AND BEARINGS MAINTENANCE (ALL EXCEPT

M1009).

This task covers:

a. Removal

d. Assembly and Preload

b. Disassembly

Adjustment

c. Cleaning and Inspection

e. Installation and Pinion

Depth Adjustment

INITIAL SETUP:

Equipment Condition

Materials/Parts

l Rear propeller shaft disconnected from

l

pinion flange. (See TM 9-2320-289-20)

l

• Rear axle differential removed.

l

(See paragraph 6-15)

l

l

Tools/Test Equipment

l Drive handle, J-8092

l

l Flange holder and remover

• Micrometer

l

l Torque wrench

Manual References

l TM 9-214

General Safety Instructions

One flange nut

One oil seal

One spacer

Seven Iockwashers

Dry cleaning solvent

(Item 23, Appendix B)

Molybdenum grease

(Item 37, Appendix B)

Gear lubricating oil

(Item 44, Appendix B)

l Dry cleaning solvent is flammable and must not be used near open flame, Use only in a

well-ventilated area.

• Compressed air used for cleaning purposes should never exceed 30 psi (207 kPa).

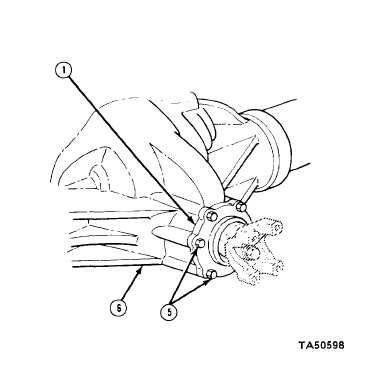

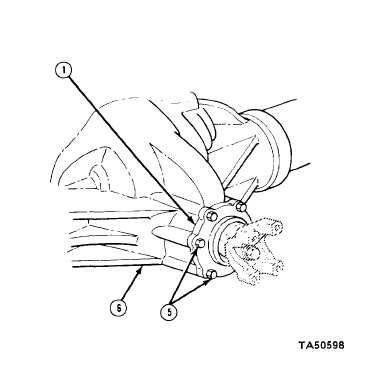

a . R E M O V A L

NOTE

It may be necessary to tap on pilot

end of drive pinion to help free

assembly from housing (6).

1.

Remove 6 bolts (5) and Iockwashers

securing retainer (1) to housing (6).

Remove retainer and drive pinion

assembly from housing. Discard

Iockwashers,

2 .

Remove

shim

located

between

retainer (1) and housing (6). Measure

thickness of shim and record, If shim

is undamaged, save for installation.

6-115