TM 9-2320-289-34

5-5.

GOVERNOR ASSEMBLY MAINTENANCE (Con’t).

3.

Install sleeve in bore of transmission and inspect for free operation in bore. Inspect valve for

free operation in bore of sleeve. If sleeve or valve bind, replace governor assembly as a unit.

4.

If a new governor assembly has been obtained, install in bore of transmission and inspect for

free operation, If governor assembly binds in bore, replace transmission case,

d.

ASSEMBLY

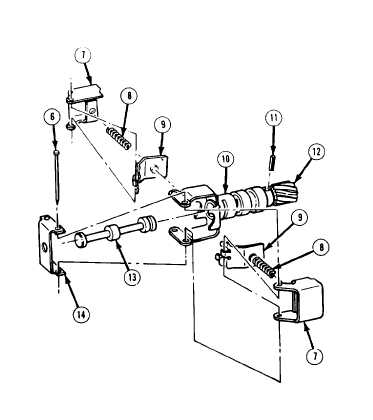

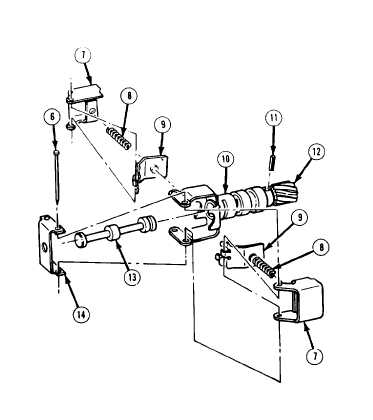

1 .

If removed install new driven gear (12) on sleeve (10). Press driven gear in until it is almost

seated, using a socket, with governor assembly (4) supported in an arbor press with two

7/64 in. (2.78 mm) plates in the exhaust openings (16). Remove any shavings from driven gear

hub and press in until it is seated.

CAUTION

Shaft portion of driven gear (12)

s h o u l d b e

supported

when

installing new Iockpin (11). Failure

to follow this caution may result in

damage to driven gear.

2 .

Using a 1/8 in. drill, drill a new pin hole

90 degrees from the existing one in

sleeve (10). Install new Iockpin (11)

through new hole in driven gear and

sleeve so that ends are just below top

of hole. Clean driven gear and sleeve

assembly to remove any shavings

that may have collected.

3 .

Install valve (13) into bore of sleeve

(10). Install 2 primary weights (7),

secondary weights (9), springs (8),

and thrust cap (14) on sleeve. Aline

pin holes and install 2 new pins (6).

Crimp ends of pins to prevent them

from falling out.

4 .

Lubricate governor assembly with

hydraulic fluid and ensure that weight

assemblies (7 and 9) operate freely

on 2 pins (6) and that valve (13)

operates freely in bore of sleeve

(10).

5 .

Inspect valve entry opening (15) with weights held all the way outward. The opening should be

0.020 in. (0.508 mm) minimum, Inspect valve exhaust opening (16) with weights held all the

way inward, The opening should be 0,020 in. (0.508 mm) minimum. If valve entry and exhaust

openings are not within specifications, replace governor assembly (4),

TA50212

5 - 2 2