TM 9-2320-280-34

6-8. ENGINE WIRING HARNESS REPLACEMENT (Cont'd)

NOTE

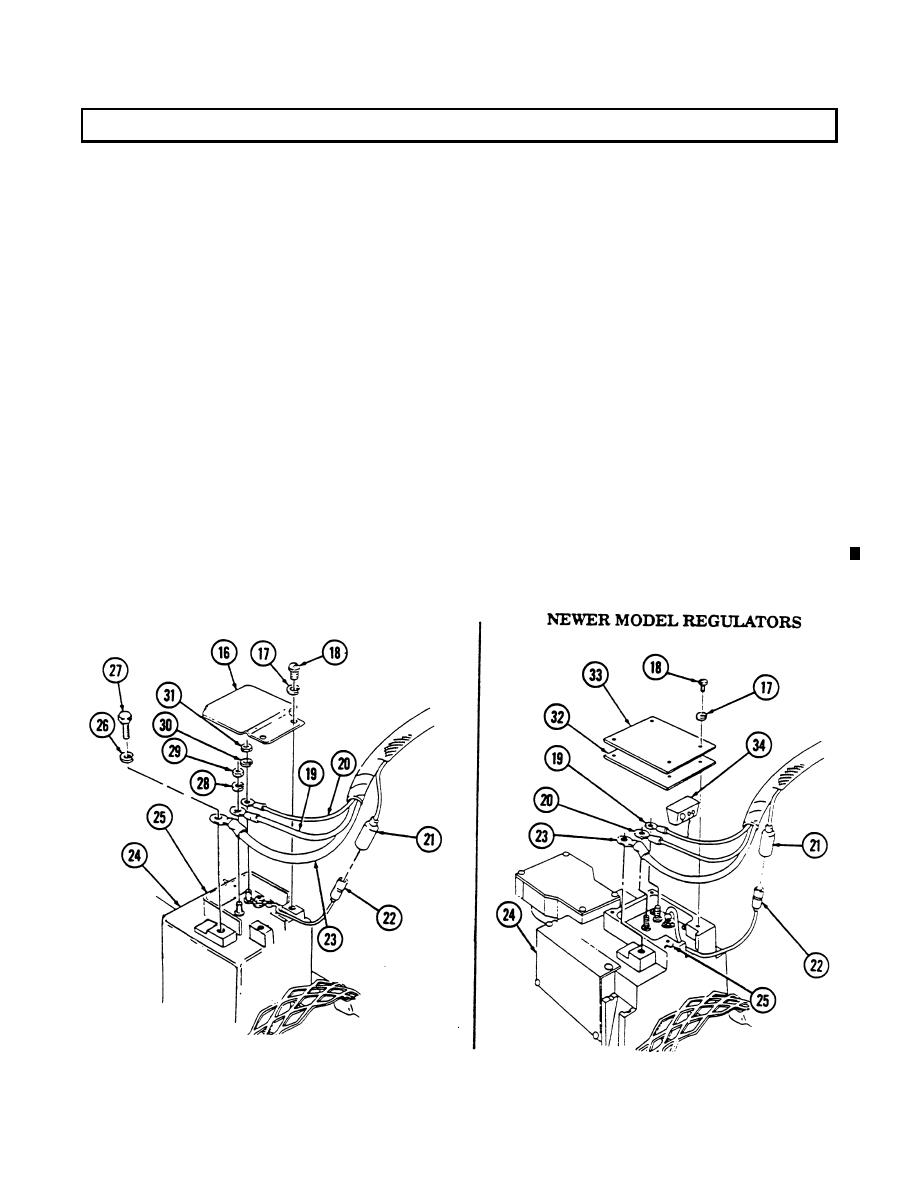

Perform steps 30 through 37 for 100 amp regulator only.

Ensure terminals are clean before connections are made.

30.

Connect lead 568A (21) to regulator lead (22).

31.

Connect lead 2A (20) to regulator (24) with lockwasher (30) and nut (31). Tighten nut (31) to 20 lb-in.

(2.3 Nm).

32.

Connect lead 5A (19) to regulator (24) with lockwasher (28) and nut (29). Tighten nut (29) to 50 lb-in.

(5.6 Nm).

NOTE

Perform steps 33 and 34 for older model regulators, and steps

35 and 36 for newer model regulators.

33.

Completely fill regulator cavity (25) with sealant to form a water tight seal. Sealant should extrude

from side of cover (16) when installed.

34.

Install cover (16) on regulator (24) with two lockwashers (17) and screws (13).

35.

Insert leads (19), (20), and (23) into sealing wedge (34) and install sealing wedge (34) in regulator

cavity (25).

36.

Install gasket (32) and cover (33) on regulator (24) with four lockwashers (17) and screws (18).

37.

Apply antiseize compound to contact surface of lead 3B (23). Install lead 3B (23) on regulator (24)

with lockwasher (26) and capscrew (27). Tighten capscrew (27) to 90 lb-in. (10 Nm).

6-81