TM 9-2320-266-34

k. Position the rotor and the drive end shield assembly

terminal junction block studs. Install the screws through

over the stator and the rectifier end shield assembly. Aline

the end shield and into the negative heat sink (figure 14-18).

the bolt holes in the stator, rectifier plate, and drive end

shields.

l. Compress the stator and both end shields manually

and install the bolts and washers. Tighten the bolts evenly.

m. Install the field brushes in the insulated holders.

Position the vertical and horizontal field brushes in the

proper location in the rectifier end shield.

n. Place the insulating washer on each field brush

terminal and install the Iockwashers and attaching screws.

Be sure that the brushes are not grounded. Tighten the

attaching screws.

o. Rotate the pulley slowly by hand to be sure that the

rotor fan blades do not hit the stator winding leads.

output (see TM 9-2320-266-20 for procedures). Output

current must be at least 47 amps.

14-6. Test Stand Operation.

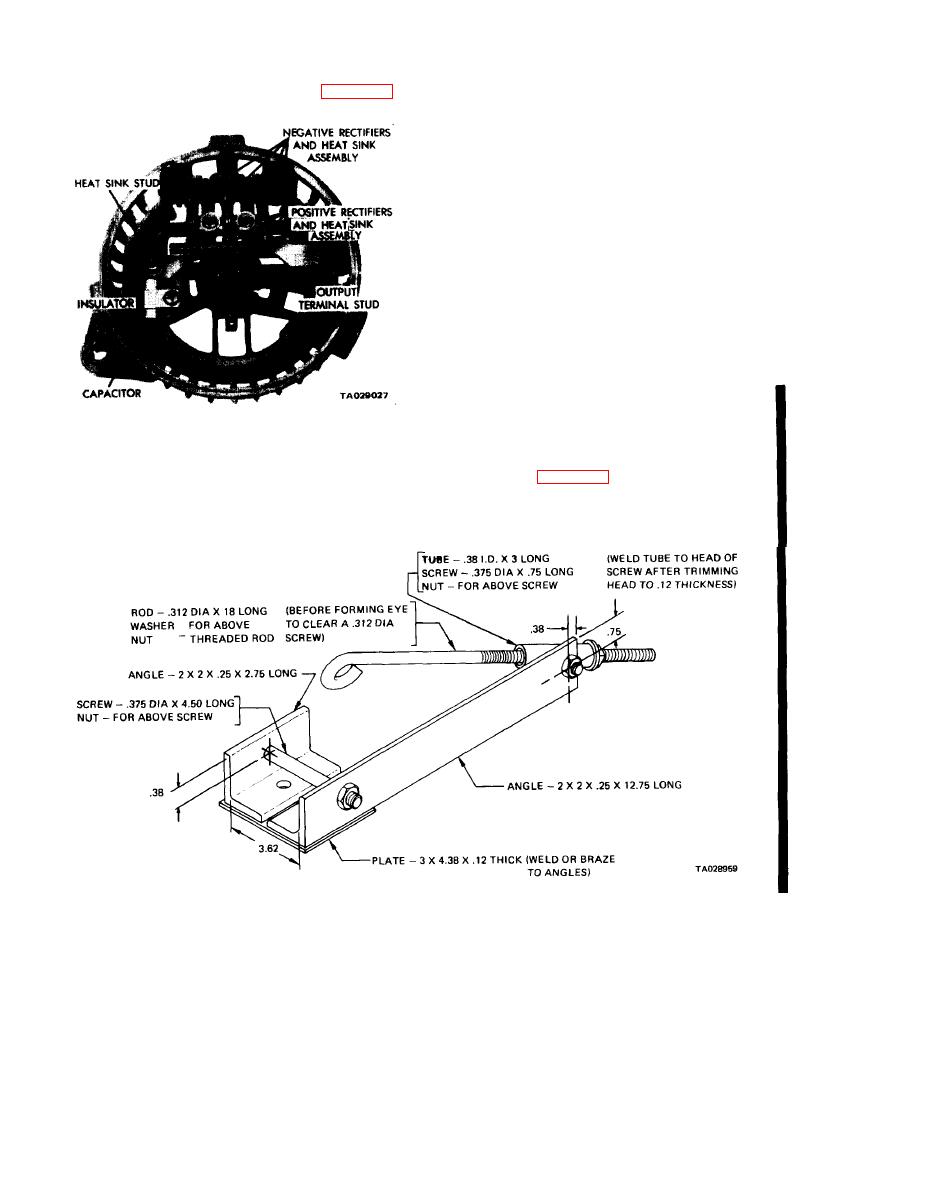

Figure 14-18. Capacitor and lnsulator Installed.

the operating procedures for the test stand.

necessary to make an adapter. Instructions for making the

install the winding terminals on the terminal block. Press

adapter are shown in figure 14-19.

the stator pins into the end shield and install and tighten

the winding terminal nuts. Route the leads so that they

cannot contact the rotor or the sharp edge of the negative

heat sink.

Figure 14-19. Test Stand Mounting Adapter.

Change 2

14-6