TM 9-2320-266-34

15-3. Cleaning the Starter Parts.

Do not immerse starter parts in solvent.

The starter-clutch outer housing, brush plate, and

pinion gear may be cleaned with a cloth moistened with

cleaning solvent. Wipe dry with a clean, dry cloth. Clean

the terminal contacts and the contactor with crocus cloth.

15-4. Testing the Armature.

a. Testing for Short Circuit. Place the armature in a

growler, and slowly rotate it while holding a thin steel

blade above and parallel to the core. A shorted armature

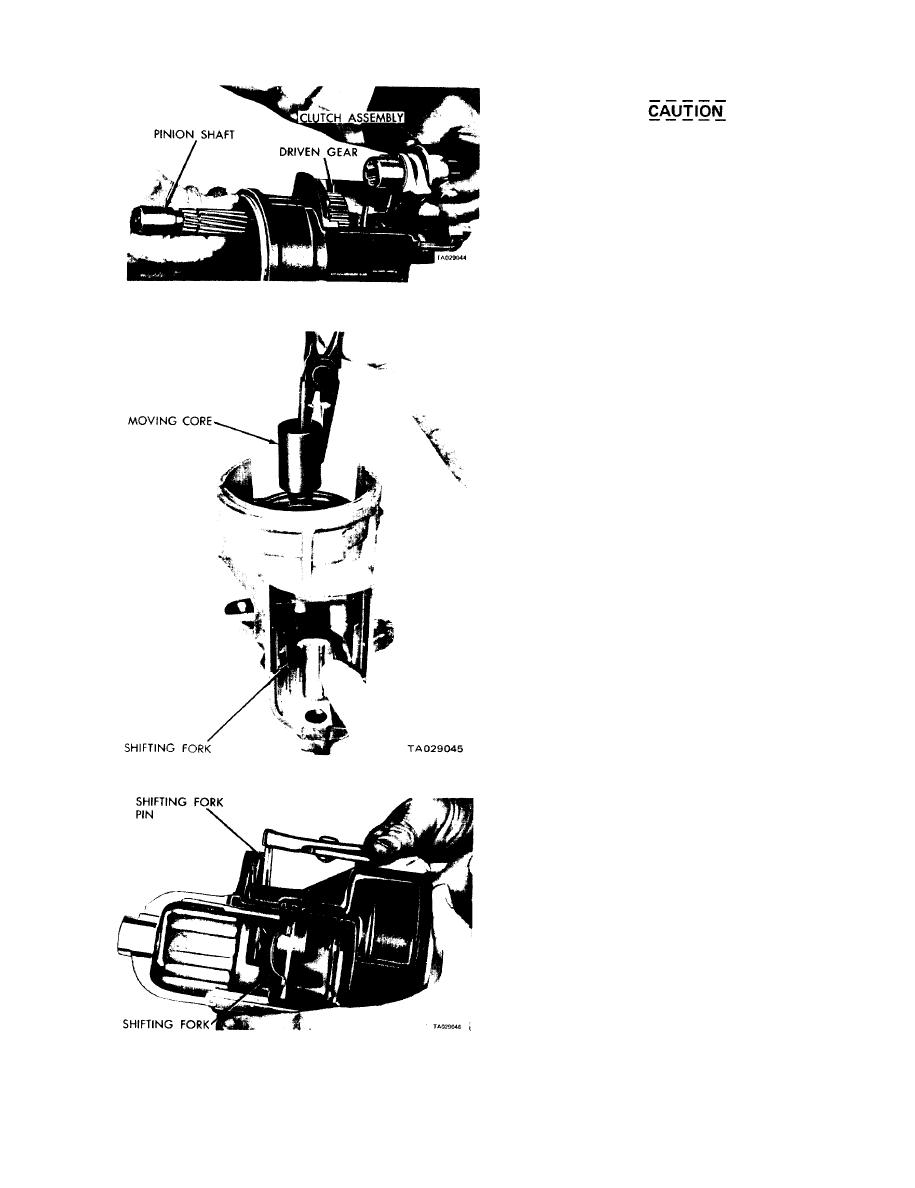

Figure 15-17. Removing Clutch Assembly.

will cause the blade to vibrate and be attracted to the core.

Replace the armature if it is shorted.

b. Testing for Ground. Connect a pair of test lamp

probes to each of the commutator riser bars and the

armature shaft. If the lamp lights up, the armature is

grounded. Replace a grounded armature.

c. Testing Commutator Runout and Refacing. Place

the armature in a pair of "V" blocks and measure both the

shaft and the commutator for runout using a dial indicator.

A bent shaft means the armature must be replaced. When

commutator runout exceeds 0.004 inch, remove enough

metal to provide a smooth, even surface. Clean the commu-

tator grooves and retest (a and b, above).

15-5. Testing the Field Coils for Ground.

a. Remove the field frame assembly from the starter.

b. Drill out the rivet attaching the field coil ground

leads to the field frame.

c. Insulate the field coil leads from the field frame.

d. Test for ground using the growler test lamp. Touch

one probe of the test lamp to the field coil lead and the

other probe to the field frame. The lamp should not light.

If it does, the field coils are grounded and require replace-

ment.

e. The field coils are replaced as part of the field-frame

assembly.

Figure 15-18. Removing Solenoid Cord.

15-6. Servicing the Starter Bushings.

Inspect the armature shaft bearing, the pinion shaft

surfaces, and the bushings for wear. Insert the bushings in

the shafts and test for side play. This indicates wear on the

bushings. Remove and replace any worn out bushings using

appropriate adapters. The end head and bushing are ser-

viced as an assembly. Pre-sized starting motor bushings are

available as service bushings; no burnishing or reaming is

required to fit them. Use a brass drift to install.

Figure 15-19. Removing Shifting Fork Pin.

15-5