TM 9-2320-266-34

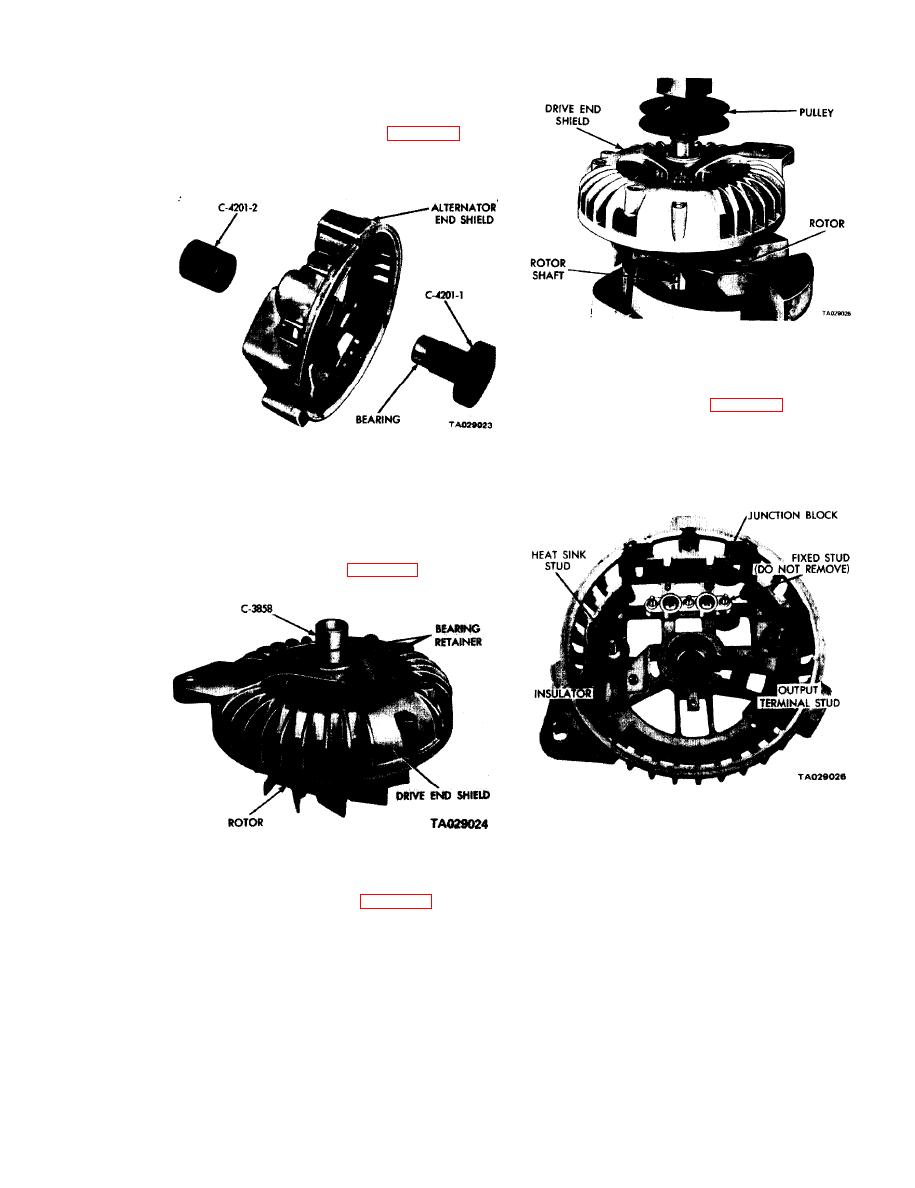

b. Position the rectifier end shield bearing on the base

of tool C-4201. Place the alternator end shield on top of

the bearing so that it is properly alined. With the top part

of tool C-4201 placed on the end shield, press it into place

until it bottoms against the alternator (figure 14-14). New

bearings are prelubricated; additional lubrication is not

required.

Figure 14-16. Installing Pulley.

f. If removed, install the output terminal stud and the

insulator through the end shield. Be sure the mica insula-

tors are in place and undamaged (figure 14-17).

g. Install the positive heat sink assembly over the studs;

guide the rectifier straps over the studs on the terminal

Figure 14-14. Installing Rectifier End Shield Bearing.

block.

c. Insert the drive cnd bearing in the drive end shield

and install the bearing retainer plate to hold the bearing

in place,

d. Position the bearing and drive end shield on the rotor

shaft and, while supporting the base of the rotor shaft, press

the bearing end shield into position on the rotor shaft with

an arbor press and tool C-3858 (figure 14-15).

Figure 14-17. Output Terminal Stud and

Insulators Installed.

h. Install the capacitor terminal over the capacitor end

Figure 14-15. Installing Drive End Shield Bearing,

stud. Install the capacitor shoulder insulator. Ground the

e. Install the pulley on the rotor shaft, The shaft of the

capacitor bracket to the end shield with a metal screw.

rotor must be supported in a manner so all pressing force is

install and tighten the positive heat sink nut and the lock-

on the pulley hub and rotor shaft (figure 14-16). Press the

washer assemblies

pulley on the rotor shaft until the pulley contacts the inner

cup of the drive and bearing.

into place in the end shield. Position the straps on the

14-5