TM 9-2320-289-34

6-17.

REAR AXLE DRIVE PINION AND BEARINGS MAINTENANCE (ALL EXCEPT

M1009) (Con’t).

2 .

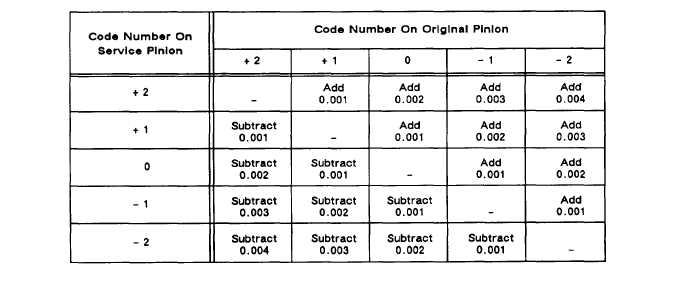

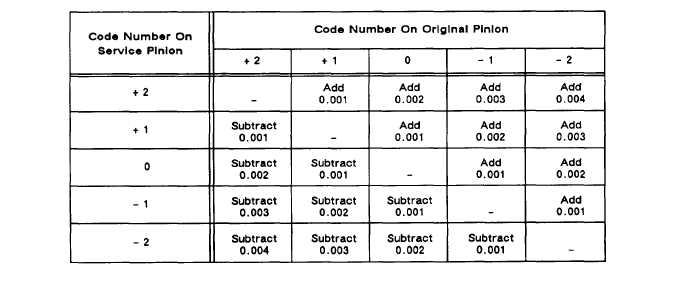

Compare depth code number with number on original drive pinion (9). Using Table 6-4, select

proper shim for preliminary setting of pinion depth,

NOTE

If code number on old and new drive pinion (9) are the same, original

shim may be reused if undamaged.

3 .

Refer to thickness of shim as measured in REMOVAL, step 2. Increase

thickness as indicated by Table 6-4:

Table 6-4. Determining Drive Pinion Shim Requirements

or decrease shim

EXAMPLE 1.

EXAMPLE 2.

If original shim measured 0.014 in. (0.36 mm),

original code was “- 1,” and new code is “+2, ”

correct shim would be:

0,014 in. + 0.003 in. = 0.017 in.

(0.36 mm + 0.08 mm = 0.43 mm)

If original shim measured 0.012 in. (0.30 mm),

original code was “+2, ” and new code is “–2,”

correct shim would be:

0.012 in. -0.004 in. = 0,008 in.

(0,30 mm -0.010 mm = 0.20 mm).

6-121