TM 9-2320-289-20

5-2.

TRANSMISSION FILTER ASSEMBLY MAINTENANCE (Con’t).

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Install new transmission oil filter assembly (9), spacer (8), new screen grommet (13), intake

pipe (14), and seal (7) into transmission housing with bolt (10), ensuring that locating tab is

alined. Tighten bolt to 125-160 lb.-in. (14–18 N•m).

NOTE

If installing a new transmission oil pan gasket (11) with transmission oil

pan (2), perform steps 4 and 6 through 12.

If applying RTV

steps 5-12.

Install new transmission

screw holes.

sealant or installing a new transmission oit pan, perform

oil pan gasket (11) on lip of transmission oil pan (2) and aline with

NOTE

Transmission oil pan (1) must be clean and dry before applying

sealant.

Apply a 3/16 in. (4.7 mm) bead of RTV sealant around lip of transmission oil

RTV

pan (2).

Install magnet (12) into transmission oil pan (2).

Install transmission oil pan (2) with 13 transmission oil pan screws (5). Evenly tighten screws to

125-160 lb.-in. (14-18 N•m).

NOTE

Steps 8 and 9 only apply to trucks equipped with winterization kits.

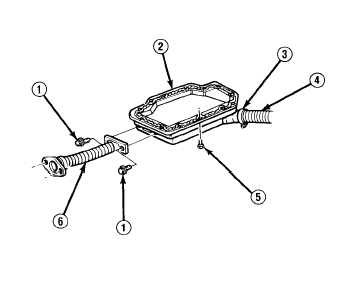

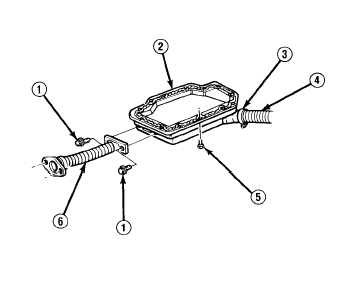

Install rear exhaust pipe (4) and

clamp (3) to rear of transmission oil

pan

(2) .

Tighten

c l a m p t o

75-95 lb.-in. (9-11 N•m).

Install heat exchange pipe (6) to front

of transmission oil pan (2) using 2

bolts

(1).

Tighten

bolts

to

25-30 lb.-in. (2-3 N•m).

Fill transmission with hydraulic fluid.

(See LO 9-2320-289-12)

With engine idling, and with parking

brake

set,

move

transmission

gearshift lever through all gear

positions, then return it to “P“ (Park).

Check hydraulic fluid level and add as

required.

Check transmission oil pan (2) for

leaks.

TA49635

5-5