TM 9-2320-280-34

This task covers:

a. Disassembly

d. Assembly

b. Cleaning

e. End Play Measurement

c. Inspection

INITIAL SETUP:

Applicable Models

Materials/Parts (Cont'd)

M997A2, M1025A2, M1035A2,

Petrolatum (Appendix B, Item 38)

M1043A2, M1045A2, M1097A2, M1123

Transmission fluid (Appendix B, Item 24)

Tools

Manual References

General mechanic's tool kit:

TM 9-2320-280-24P

automotive (Appendix G, Item 1)

Equipment Condition

Special Tools

Transmission disassembled into subassemblies

Seal protectors (Appendix G, Item 46)

Materials/Parts

Maintenance Level

O-ring (Appendix E, Item 142)

General support

O-ring (Appendix E, Item 145)

NOTE

Work area should be well-ventilated, clean, and free from blowing

dirt and dust.

a. Disassembly

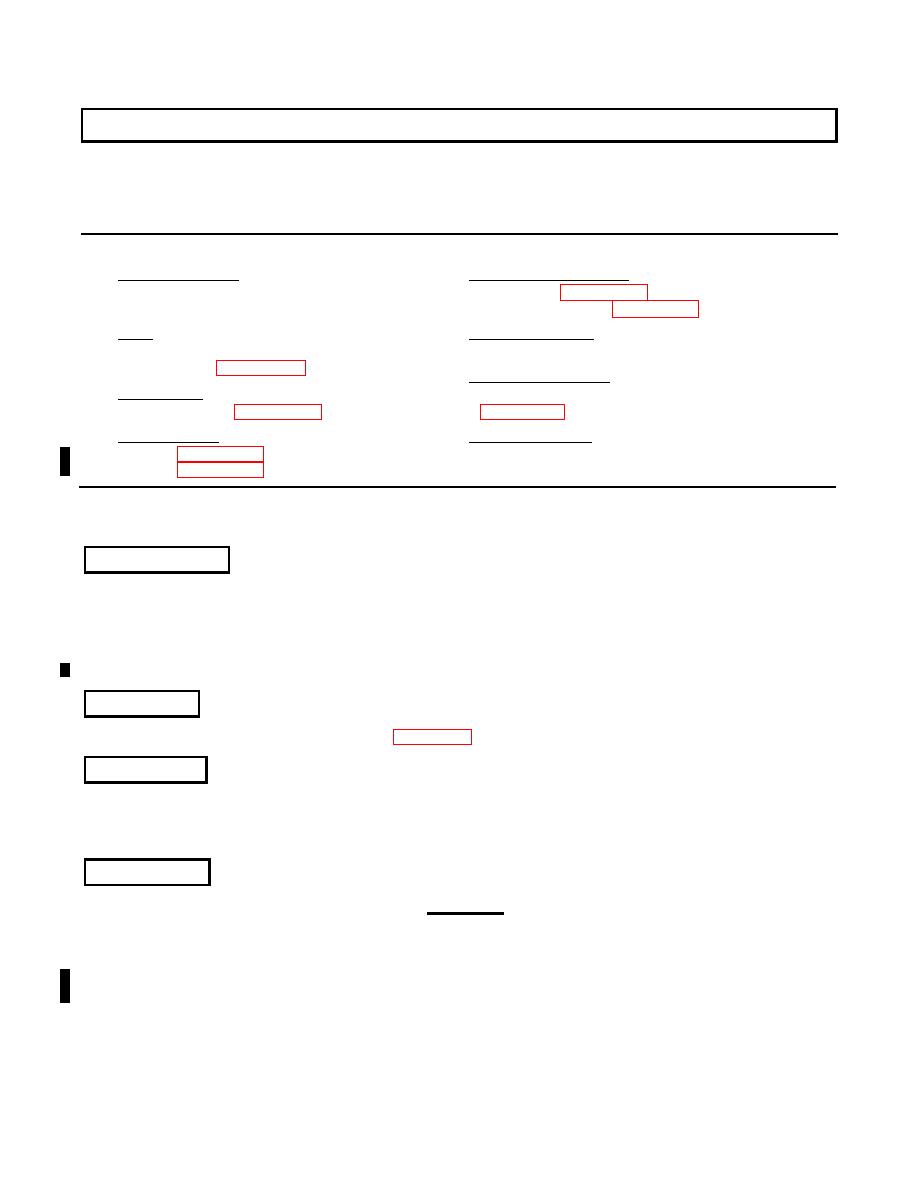

1.

Remove snapring (1), backing plate (11), four clutch plates (9), and clutch plate assemblies (10) from

clutch housing (4).

2.

Remove snapring (8) and spring and retainer assembly (7) from clutch housing (4).

3.

Remove piston (3) from clutch housing (4).

4.

Remove O-ring (2) from piston (3) and O-ring (6) from housing (4). Discard O-rings (2) and (6).

b. Cleaning

Clean all components in accordance with para. 2-13.

c. Inspection

1.

Inspect piston (3), backing plate (11), and clutch housing (4) for cracks, breaks, and damaged seal

ring grooves. Replace any that are cracked, broken, or damaged.

2.

Inspect plug (5). If missing, replace clutch housing (4).

d. Assembly

CAUTION

All transmission parts must be lubricated with clean transmission

fluid (Dexron III) before assembly. Foreign material will cause

transmission damage.

1.

Install O-ring (2) on piston (3), with lip facing toward spring and retainer assembly (7) side.

2.

Install O-ring (6) on housing (4), with lip facing away from spring and retainer assembly (7) side.

3.

Place inner seal protector J38731-1 on clutch housing (4).

4.

Place outer seal protector J38731-2 on piston (3).

5.

Position piston (3) on base J38731-3 with snapring groove of piston (3) up.

6.

Place housing (4) over piston (3) while holding inner seal protector in position.

Change 2