TM 9-2320-280-34

This task covers:

a. Disassembly

d. Assembly

b. Cleaning

e. Direct Clutch Piston Movement Measurement

c. Inspection

INITIAL SETUP:

Applicable Models

Materials/Parts

M997A2, M1025A2, M1035A2,

Direct clutch seal (Appendix E, Item 211)

M1043A2, M1045A2, M1097A2, M1123

Inner piston seal (Appendix E, Item 216)

Outer piston seal (Appendix E, Item 217)

Tools

Transmission fluid (Appendix B, Item 24)

General mechanic's tool kit:

Equipment Condition

automotive (Appendix G, Item 1)

Transmission disassembled into subassemblies

Special Tools

Clutch spring compressor

General Safety Instructions

(Appendix G, Item 47)

Adapter (Appendix G, Item 48)

Air pressure must not exceed 80 psi (552 kPa)

Adapter (Appendix G, Item 45)

when air checking clutch piston.

Seal protectors (Appendix G, Item 46)

Maintenance Level

Manual References

General support

TM 9-2320-280-24P

NOTE

Work area should be well-ventilated, clean, and free from blowing

dirt and dust.

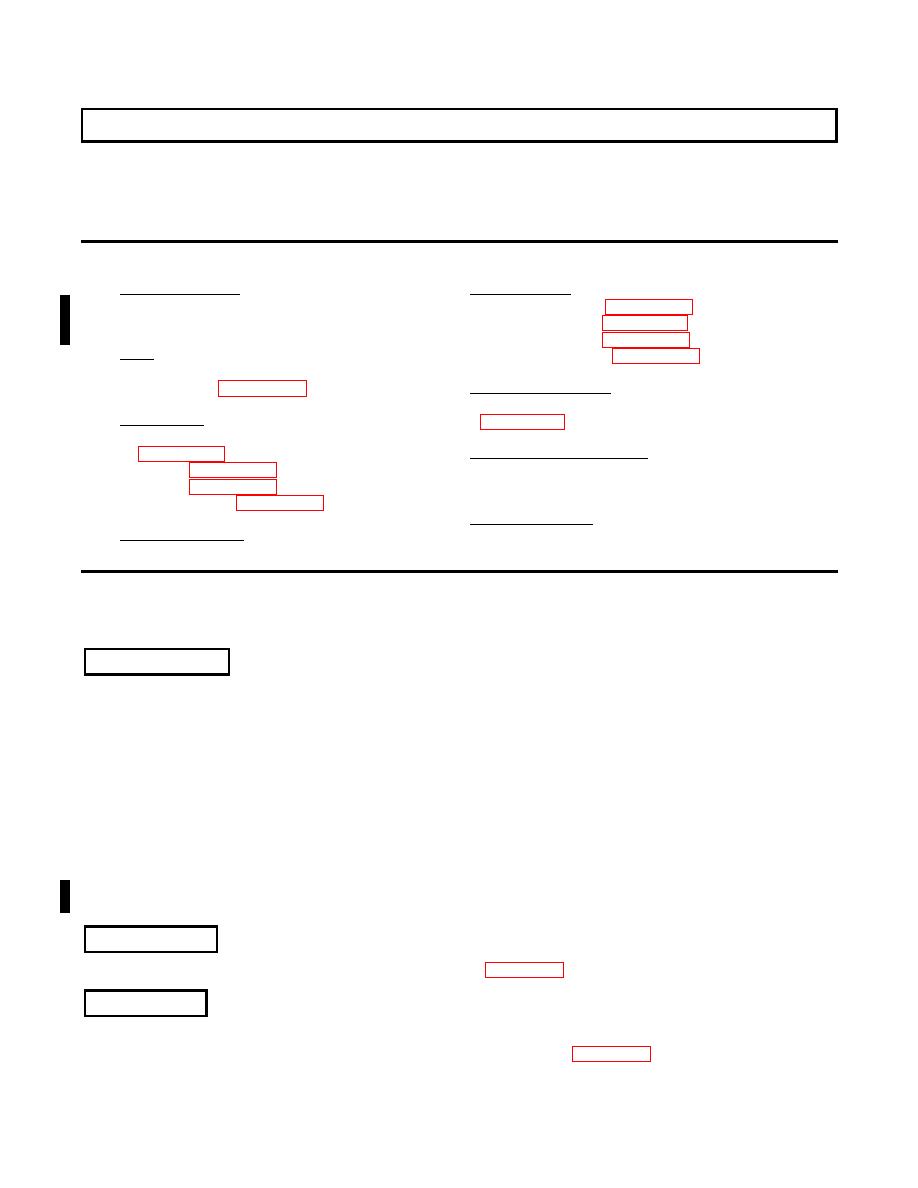

a. Disassembly

1.

Remove snapring (1), clutch retainer (2), and outer race (3) from direct clutch housing (5).

2.

Remove sprag assembly (4) from direct clutch housing (5).

3.

Remove snapring (6), backing plate (7), five clutch plate assemblies (8), clutch plates (10), and

dished plate (9) (1995-1996 transmission only) from direct clutch housing (5).

NOTE

Piston removed in step 4 is for 1995-1996 transmissions only.

4.

Using spring compressor, adapter, and clutch spring adapter, remove snapring (11), spring and

retainer assembly (12), and piston (13) from clutch housing (5).

NOTE

Perform step 5 for 1995-1996 transmissions only.

5.

Remove inner seal (14), outer seal (15), and direct clutch seal (16) from clutch housing (5).

Discard seals (14), (15), and (16).

b. Cleaning

Clean all direct clutch components in accordance with para. 2-13.

c. Inspection

NOTE

For general inspection instructions, refer to para. 2-14.

1.

Inspect backing plate (7), five clutch plates (10), and dished plate (9) (1995-1996 transmission only)

for signs of burning, scoring, or cracks. Replace any plate if burned, scored, or cracked.

Change 2