TM 9-2320-289-34

10-24. AIR CONDITIONER COMPRESSOR MAINTENANCE (M1010) (Con’t).

12.

13.

14.

1 5.

16.

Gently tap pulley (23) with pulley bearing (22) into place until it seats. Check pulley to ensure

that it rotates freely. Install pulley snapring (20).

NOTE

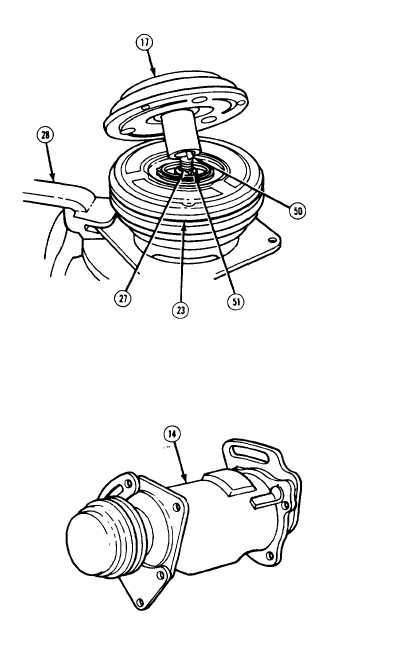

Key (50) has a slight curve for interference fit with keyway of clutch (17).

Insert key (50) into keyway of clutch

(1 7), Allow key to project 3/16 in.

(4.8 mm) out of keyway. Aline key

with shaft keyway (51) and position

clutch on shaft (27).

Hold clutch (17) in place with clutch

hub holder. Using hub and drive puller

and installer, install clutch until there

is about 3/32 in. (2.4 mm) clearance

between clutch and pulley (23).

Ensure that key (50) stays in place.

Install clutch snapring (19). Install

new locknut (18). Tighten locknut to

25 Ib.-ft. (34 N.m).

Check to ensure that there is

0.022-0.057 in.

(0.6-0.14 mm)

clearance between clutch (17) and

pulley (23).

If clearance is not

correct, check for mispositioned key

(50) or shaft (27).

e.

INSTALLATION

1 .

2 .

3 .

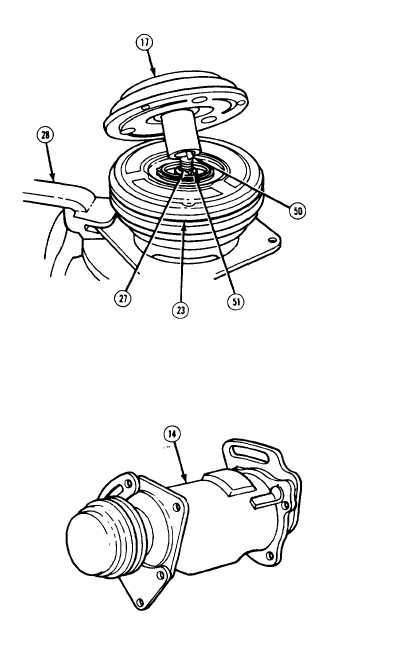

If there are no signs of refrigerant

leakage in air conditioning system,

add refrigerant oil to compressor (14)

equal to the amount drained from

compressor, plus 1 oz. (0.059 1).

If there are signs of refrigerant oil

leakage in air conditioning system,

remove

receiver-dehydrator (see

paragraph 10-27), and drain and

measure

refrigerant

oil.

Add

refrigerant oil to compressor (14)

equal to this amount plus amount

drained from compressor. Install

receiver-dehydrator. (See paragraph

10-27)

Install drain screw and new gasket on

compressor assembly (14).

TA50460

10-97