TM 9-2320-289-34

7-4.

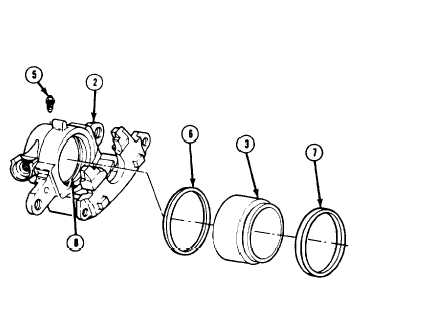

CALlPER REPAIR (Con’t).

CAUTION

DO NOT use metal tool to remove piston seal (6), Be careful not to scratch

caliper bore (8) when removing dust boot (7). Failure to follow this caution

may result in damage to caliper bore.

2 .

Remove dust boot (7) and piston seal (6) from caliper bore (8). Discard dust boot and piston

seal. Remove bleeder valve (5).

b.

CLEANING AND INSPECTION

WARNING

l

l

Alcohol used in this procedure is highly flammable and poisonous.

Drinking of this alcohol can cause blindness and death. Avoid inhaling

its fumes. Keep away from open flame.

Compressed air used for cleaning purposes should never exceed 30 psi

(207” kPa), Use only effective chip guarding and personal protective

equipment (goggles/shield, gloves, etc.), Failure to follow this warning

may result in injury to personnel.

CAUTION

DO NOT use emery cloth or any other form of abrasive. If crocus cloth is

used on caliper bore (8), ensure that caliper (2) is thoroughly cleaned

before assembly, Failure to follow this caution may result in damage to

caliper assembly.

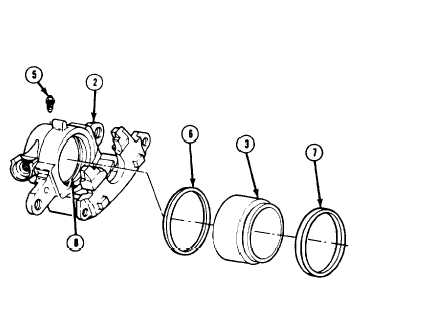

1 .

Clean exterior of caliper (2) with

clean soapy water.

2.

Clean caliper bore (8), caliper

passages,

and

piston

(3)

with

denatured alcohol. Using dry, filtered,

compressed air, dry parts and blow

out all passages in caliper (2) and

bleeder valve (5).

3.

Inspect sliding surfaces of caliper (2)

and caliper bore (8) for scoring,

pitting, or corrosion, Replace caliper

if surface defects cannot be cleaned

with crocus cloth,

4.

Inspect piston (3) and for scoring,

nicks,

corrosion,

and

w o r n or

damaged plating. Replace piston if

any defects are found.

5 .

Using crocus cloth, clean caliper

mounting surfaces on truck and

remove any defects or corrosion.

TA50387

7-17