TM 9-2320-289-34

7-2.

DRUM AND ROTOR REPAIR (Con’t).

b .

ROTOR REPAIR

WARNING

DO NOT use a rotor that will not meet minimum wear specifications.

Failure to follow this warning may result in brake failure and serious injury

or

l

l

death to personnel.

NOTE

Light scoring of rotor surface not in excess of 0.015 in. (0.381 mm) in

depth is normal and will not affect brake operation.

Parallelism is the measurement of the thickness of rotor at 4 or more

points around circumference of rotor. All measurements must be

made at the same distance in from edge of rotor, Thickness must not

vary by more than 0,0005 in. (0,0127 mm) from point to point.

1.

Measure thickness of rotor at 4 points around circumference. If rotor measures less than

1.215- in. (30.86 mm) (M1009) or’ 1.465 in. (37.21 mm) (all except M1009), discard rotor.

2.

If rotor thickness varies over 0.0005 in. (0.0127 mm), refinish to Table 7-2 specifications.

Table 7-2. Rotor Thickness

M o d e l

Mminimum After Refinishing

Replacement/ Discard

M1009

1.230 in. (31.24 mm)

1,215 in. (30.86 mm)

All Except Ml 009

1.480 in. (37.59 mm)

1.465 in. (37.21 mm)

I

1

3.

Check lateral runout.

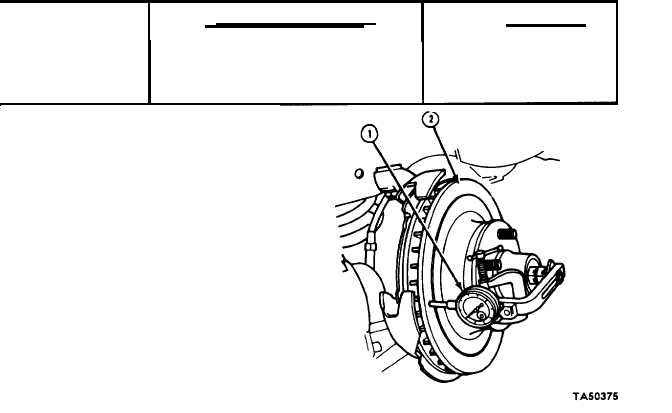

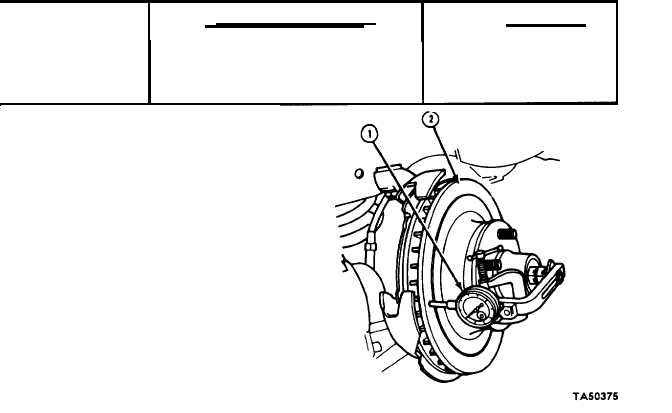

(a)

(b)

(c)

(d)

Install rotor. (See TM 9-2320-

289-20)

Tighten

wheel

bearings to

eliminate freeplay.

Attach dial indicator (1) to some

portion of suspension. Point of

plunger must contact rotor face

(2) about 1 in. (25 mm) from

rotor edge.

Move rotor 1 complete rotation.

Lateral runout should not exceed

0.004 in. (0.102 mm). If lateral

runout

exceeds

0.004 in.

(O. 102 mm), machine rotor.

7-3