TM 9-2320-289-20

7-7.

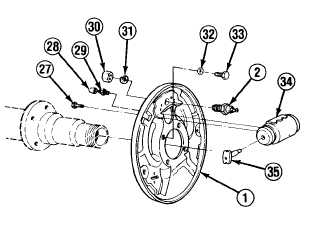

BRAKE SHOE AND WHEEL CYLINDER REPLACEMENT (Con’t).

2.

Install wheel cylinder (34) on backing plate (1) with 2 bolts (27). Tighten bolts to 15 Ib.-ft.

(20 N•m). Install 2 link rods (35), bleeder valve (29), and cap (28) if removed.

NOTE

M1009

DOES

NOT

use

a

Iockwasher (31) with anchor pin

(2).

3.

Install

anchor

pin

(2)

with

new

I o c k w a s h e r ( 3 1 ) a n d n u t ( 3 0 ) if

removed. Tighten nut to 230 Ib.-ft.

(312 N•m).

NOTE

Primary brake shoe (17) has a

shorter lining than the secondary

brake shoe (5), and is always

installed toward front of truck.

4.

5.

6.

7.

8.

9.

10.

11.

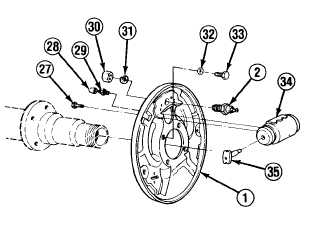

C o n n e c t p a r k i n g b r a k e c a b l e to

parking

brake

lever

(3)

if

disconnected.

Install washer (4) on parking brake lever (3) pin. Install secondary brake shoe (5) on parking

brake lever pin. Install clip (6) on secondary brake shoe.

Install pin (18) in backing plate (1) on secondary brake shoe (5) side. Position adjusting lever

(24), adjusting spring (22), and pivot (21) assembly, ensuring that pin (18) is through

secondary brake shoe and adjusting lever hole.

Install pivot (16), spring (15), and hold-down washer (14), turning hold-down washer to lock in

place on pin (18).

Position primary brake shoe (17) and install pin (18), pivot (16), spring (15), and hold-down

washer (14), turning hold-down washer to lock in place.

Install brake shoe guide (7) on anchor pin (2). Install actuating link (20) on pivot (21) and

anchor pin.

Hook adjusting spring (25) on secondary brake shoe (5) and primary brake shoe (17).

With primary brake shoe (17) moved forward, install strut spring (13) and parking brake strut

(8). Ensure that link rods (35) are engaged in secondary brake shoe (5) and primary brake

shoe notches.

TA49668

7-18