TM 9-2320-280-34

This task covers:

a. Disassembly

c. Inspection

b. Cleaning

d. Assembly

INITIAL SETUP:

Applicable Models

Manual References

All vehicles except: M997A2, M1025A2,

TM 9-2320-280-24P

M1035A2, M1043A2, M1045A2, M1097A2,

Equipment Condition

M1123

Transmission disassembled into

Tools

subassemblies (para. 17-3).

General mechanic's tool kit:

General Safety Instructions

automotive (Appendix G, Item 1)

Air pressure must not exceed 15 psi (103 kPa)

Special Tools

when air check clutch piston.

Driver handle (Appendix G, Item 34)

Bushing service set (Appendix G, Item 33)

Maintenance Level

Materials/Parts

General support

Preformed packing (Appendix E, Item 180)

Preformed packing (Appendix E, Item 182)

Four packing retainers (Appendix E, Item 188)

Transmission fluid (Appendix B, Item 23)

NOTE

Work area should be well ventilated, clean, and free from blowing

dirt and dust.

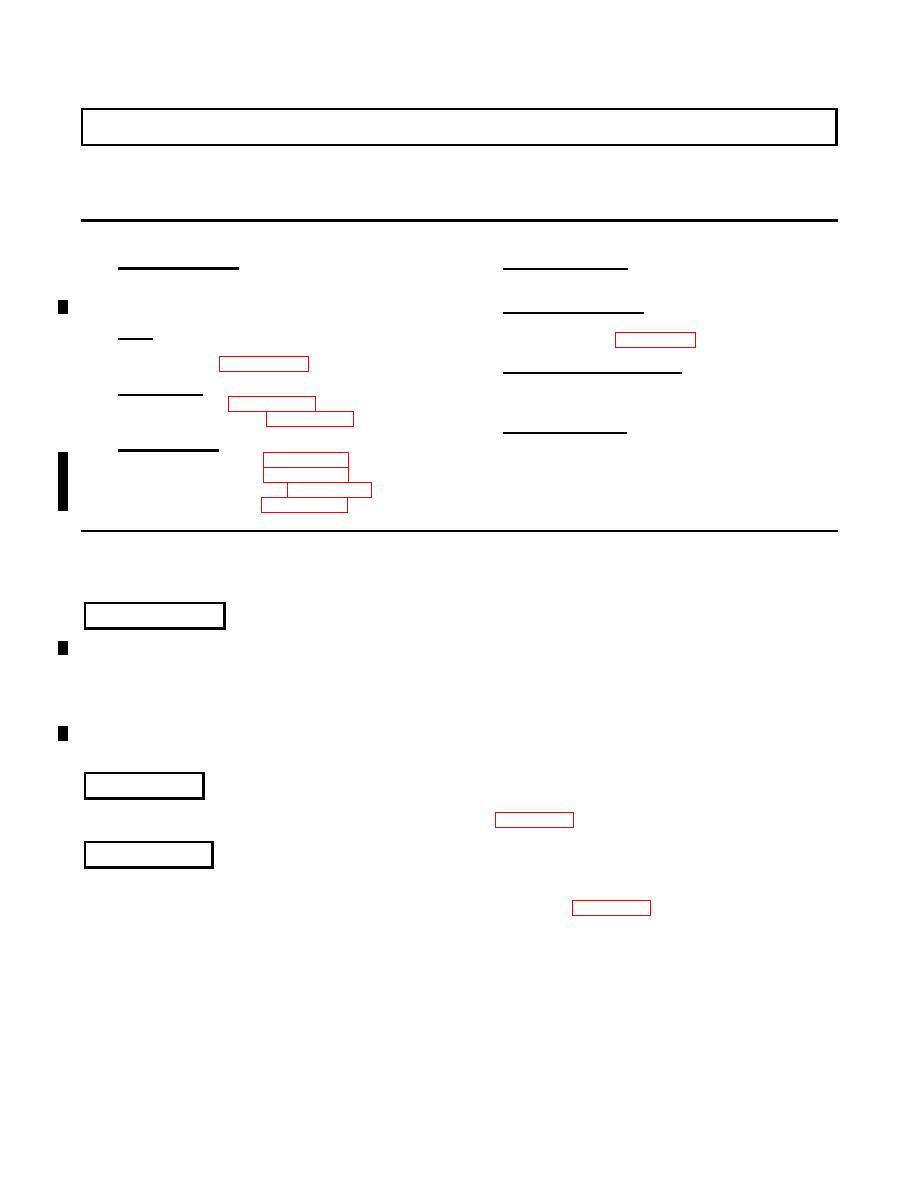

a. Disassembly

1.

Remove four packing retainers (1) from center support (2). Discard packing retainers (1).

2.

Compress spring retainer (11), and remove snapring (5) and spring retainer (11) from center

support (2).

3.

Remove three release springs (10), spring guide (9), and clutch piston (6) from center support (2).

4.

Remove preformed packings (7) and (8) from clutch piston (6). Discard preformed

packings (7) and (8).

b. Cleaning

Clean all center support components in accordance with para. 2-13.

c. Inspection

NOTE

For general inspection instructions, refer to para. 2-14.

1.

Inspect roller clutch inner race (3) for damage. Replace center support (2) if damaged.

2.

Inspect oil ring grooves (4) in center support (2) for roughness or damage. Replace center

support (2) if damaged.

3.

Inspect center support (2) for damage. Replace if damaged.

4.

Check all oil passages in center support (2) for blockage.

5.

Inspect release springs (10) for signs of distortion or collapsed coils. Replace all springs (10) if any

have distorted or collapsed coils.

6.

Inspect clutch piston (6), spring guide (9), spring retainer (11), and snapring (5) for damage or

distortion. Replace any part if damaged or distorted.

Change 2