TM 9-2320-280-34

This task covers:

a. Alternator Output Testing

d. Cleaning

b. Disassembly

e. Assembly

c. Static Testing

INITIAL SETUP:

Applicable Models

Personnel Required

M996, M996A1, M997, M997A1

One mechanic

One assistant

Tools

Manual References

General mechanic's tool kit:

TM 9-2320-280-20

automotive (Appendix G, Item 1)

TM 9-2320-280-24P

Puller (Appendix G, Item 136)

TM 9-4910-663-12

Test Equipment

TM 9-4910-485-12

Multimeter (Appendix G, Item 120)

Equipment Condition

Test stand (Appendix G, Item 94)

Alternator removed (TM 9-2320-280-20).

Materials/Parts

General Safety Instructions

Nine locknuts (Appendix E, Item 76)

Always support alternator core and shaft

Locknut (Appendix E, Item 66)

assembly during removal and installation.

Six lockwashers (Appendix E, Item 90)

Nine locknuts (Appendix E, Item 68)

Maintenance Level

Four lockwashers (Appendix E, Item 109)

Direct support

Sealing compound (Appendix B, Item 51)

Sealing compound (Appendix B, Item 54)

Sealing compound (Appendix B, Item 55)

Sealant (Appendix B, Item 43)

a. Alternator Output Testing

1.

Mount pivot arm of 500 amp test stand to high-speed side and screw mounting flange adapter to

pivot arm, and connect pulley drive shaft to high-speed head. Screw pulley drive shaft to mounting

flange adapter.

2.

Mount alternator to starter/alternator mounting bracket on 500 amp test stand, and connect V-belt

from 500 amp test stand pulley to alternator pulley. Adjust belt tension.

3.

Connect cable from alternator ground terminal to 500 amp test stand G- terminal. Connect cable

from alternator "Bat" terminal to 500 amp test stand G+ terminal. Connect cable from alternator

regulator IGN to 500 amp test stand F terminal.

4.

Make a jumper wire with a ring terminal at both ends. Connect jumper wire on 500 amp test stand

from IGN SWITCH terminal to F-B terminal.

NOTE

Prior to operation of the test stand, ensure all switches and controls

are in the "initial" positions as referenced in Operator and

Maintenance Manual, TM 9-4910-663-12 (UMC Model GSAR-500), or

Operator and Maintenance Manual, TM 9-4910-485-12 (Sun Model

AGT-99A).

Model AGT-99A

5.

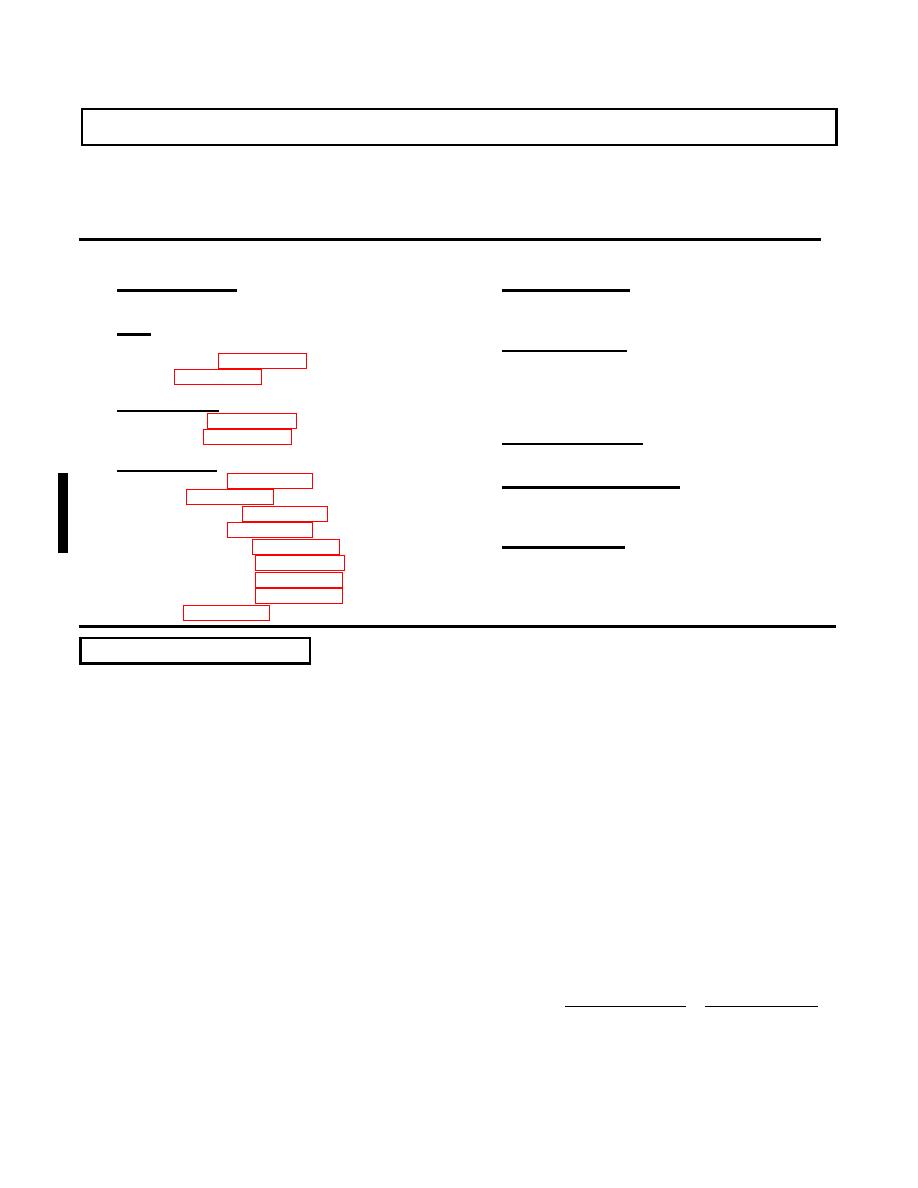

Set 500 amp test stand as follows:

Model GSAR-500

(a) DC ammeter load and starter selector

X10

500 amp

(b) DC ammeter field and battery charge selector

X1

5 amp

(c) Field circuit switch

Regulator

Regulator

(d) DC voltmeter circuit selector

RECT/GEN

RECT/GEN

Change 2