TM 9-2320-289-34

3-45.

FUEL INJECTOR PUMP CALIBRATION (Con’t).

c .

ADJUSTMENT

1 .

2 .

3 .

4 .

5 .

NOTE

Adjustment in step 1 should be made during applicable step, Adjustments

in steps 2-5 should be made after all calibration is completed, unless

otherwise stated,

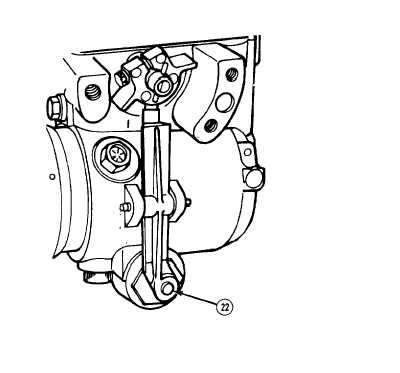

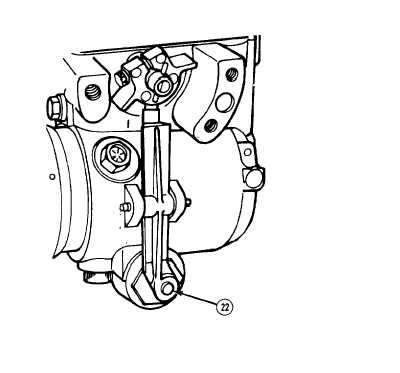

If any throttle advance gage (13)

reading is not correct, adjust position

of servo adjusting screw (22) to obtain

proper reading. After all testing is

complete, apply pipe sealant to servo

adjusting screw.

If any flowmeter reading is too low,

replace metering screw with a smaller

metering

screw.

(See paragraph

3-39)

If any flowmeter reading is too high,

replace metering screw with a larger

metering screw.

(See paragraph

3-39)

If any housing pressure reading is not

correct, test fuel injector pump. (See

paragraph 3-44) If no leaks are

detected, remove hydraulic head and

check for

incorrectly

assembled

components. (See paragraph 3-42)

If any transfer pump pressure reading

is not correct, remove transfer pump

blades and regulator and check for

incorrectly assembled components.

(See paragraph 3-41 )

d .

PRELIMINARY TESTING

1. Set test stand supply pump boost pressure at 4.5-5.5 psi (31-38 kpa).

NOTE

Test specifications refer to engine rpm. Most test stand tachometers

register fuel injector pump rpm, which is half of engine rpm. Ensure that

proper adjustments are made during calibration.

2.

Set rpm at 2000, with throttle lever (17) in wide open throttle position. Allow fuel injector pump to

run for 10 minutes to clear remaining air from system and bring fuel injector pump to operating

temperature.

3.

Set rpm at 2000, with throttle lever (17) in wide open throttle position. Set transfer pressure gage

(6) to indicate 58-64 psi (400-441 kPa). Flowmeter reading must be 225-375 cc, Perform

ADJUSTMENT if necessary.

T A 5 0 7 57

3-164

Change 2