TM 9-2320-289-34

3-18.

CRANKSHAFT, MAIN BEARINGS, AND FLYWHEEL INSTALLATION (Con’t).

4.

Install rear main seal. (See paragraph 3-34)

CAUTION

Ensure that main bearing caps (2) are fully seated before installing bolts (3

and 4). Failure to follow this caution may result in damage to main bearing

caps.

5.

Coat inner surface of lower main bearing (5) with lubricating oil and install in main bearing cap

(2) as marked. Using soft-faced hammer, tap main bearing cap into place and install with 2

inner bolts (4) and 2 outer bolts (3). Repeat this step for each main bearing cap that was

removed.

NOTE

l Bearing cap #3 bolts should not be tightened to full specifications yet,

l Inner bolts (4) are longer than outer bolts (3),

6.

Tighten inner bolts (4) and outer bolts (3) to 40 Ib. -ft. (54 N.m). Evenly tighten inner bolts

again to 110 Ib. -ft. (149 N.m). Evenly tighten outer bolts again to 100 Ib.-ft. (136 N.m).

7.

Tighten bearing cap #3 inner bolts (4) and outer bolts (3) to 10 Ib. -ft, (14 N.m). Using

soft-faced hammer, tap end of crankshaft (6) rearward, then forward, to line up #3 main

bearing (5) with crankshaft thrust surface. Perform step 6 for bearing cap #3.

8.

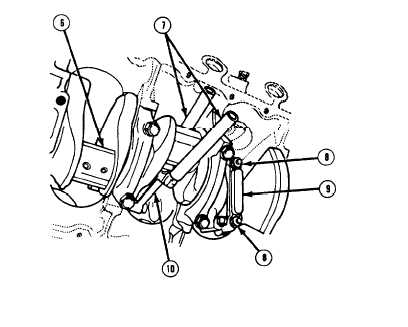

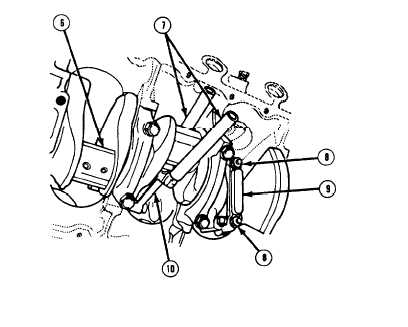

Coat surface of connecting rod

bearings with lubricating oil. Push

pistons down to engage connecting

rods on connecting rod journals.

Remove short pieces of 3/8 in. I.D.

hose (7) from threads of connecting

rod (1 O) bolts immediately before

installing connecting rod caps (9).

Install 8 connecting rod caps on

crankshaft (6) journals as marked

with 16 new nuts (8). Evenly tighten

nuts to 45-50 Ib.-ft. (61-68 N.m).

TA50668

3 - 5 9