TM 9-2320-289-34

3-14.

CHECKING MAIN BEARING CLEARANCE (Con’t).

CAUTION

Ensure that main bearing caps (1) are fully seated before installing bolts (2

and 3). Failure to follow this caution may result in damage to main bearing

caps.

l

l

NOTE

Inner bolts (3) are longer than outer bolts (2).

Ensure that lubricating oil is applied to bolt (2 and 3) threads before

installation,

3.

Using soft-faced hammer, tap main bearing #3 cap (1) into place and install 2 inner bolts (3)

and 2 outer bolts (2). Tighten all bolts to 40 Ib. -ft. (54 N-m). Evenly tighten inner bolts again to

110 Ib.-ft. (149 N.m). Evenly tighten outer bolts again to 100 Ib.-ft. (136 N.m).

NOTE

Scale on envelope (7) of gaging plastic (6) should be used to measure

clearance.

DO NOT rotate crankshaft (5) while gaging plastic (6) is between main

bearing (4) and crankshaft.

This will result in an inaccurate

measurement.

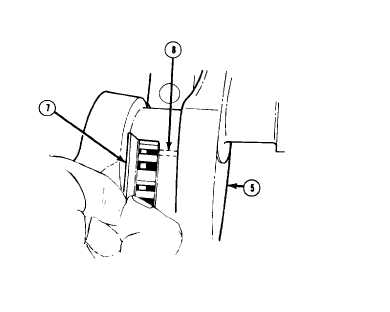

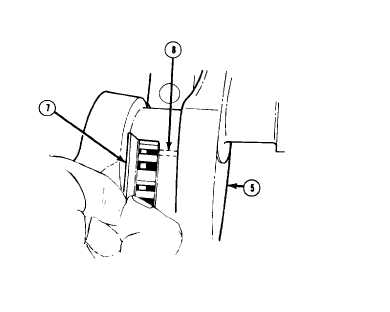

4.

Remove 2 inner bolts (3), 2 outer

bolts (2), and main bearing #3 cap

(1). Measure flattened gaging plastic

(8) at widest point to determine main

bearing clearance. Preferred main

bearing

clearance

is 0.0018 in.

(0.0457 mm) for main bearings #1-4

and 0.0033 (0.0838 mm) for main

bearing #5. Clearance should be no

more than 0.005 in. (0.127 mm).

5.

Measure flattened gaging plastic (8)

at

each

end

and

middle,

and

compare

readings.

Maximum

difference between ends and middle

(taper)

should

be

0.001 in.

(0.025 mm). If there is taper,

measure

crankshaft (5) journal.

Replace

crankshaft if

there

is

excessive taper. (See paragraph

3-1 5) Discard gaging plastic.

6.

If measurements in steps 4 and 5 are not correct, replace main bearing (4) (see

paragraph 3-1 5) and repeat steps 2-5. If still not within specifications, use undersized main

bearing. If smallest undersized bearing has been used, replace crankshaft (5). (See

paragraph 3-1 5)

TA50656

3 - 4 5