TM 9-2320-280-34

This task covers:

a. Preliminary Inspection and Cleaning

c. Inspection

b. Disassembly

d. Assembly

INITIAL SETUP:

Applicable Models

Manual References

M997, M997A1

TM 9-2320-280-24P

Tools

Equipment Condition

General mechanic's tool kit:

Air-conditioning compressor removed

automotive (Appendix G, Item 1)

Test Equipment

General Safety Instructions

Multimeter (Appendix G, Item 120)

Compressed air for cleaning purposes will

not exceed 30 psi (207 kPa).

Special Tools

Compressor cylinder block may be

Compressor tool kit (Appendix G, Item 102)

pressurized.

Materials/Parts

Maintenance Level

O-ring (Appendix E, Item 130)

Direct support

Seal kit (Appendix E, Item 48)

Gasket kit (Appendix E, Item 39)

Direct clutch parts kit (Appendix E, Item 154)

Lubricating oil (Appendix B, Item 35)

NOTE

The following procedure applies to vehicles with R-12 refrigerant

only. Refer to para. 14-27.1 for vehicles with R-134a refrigerant.

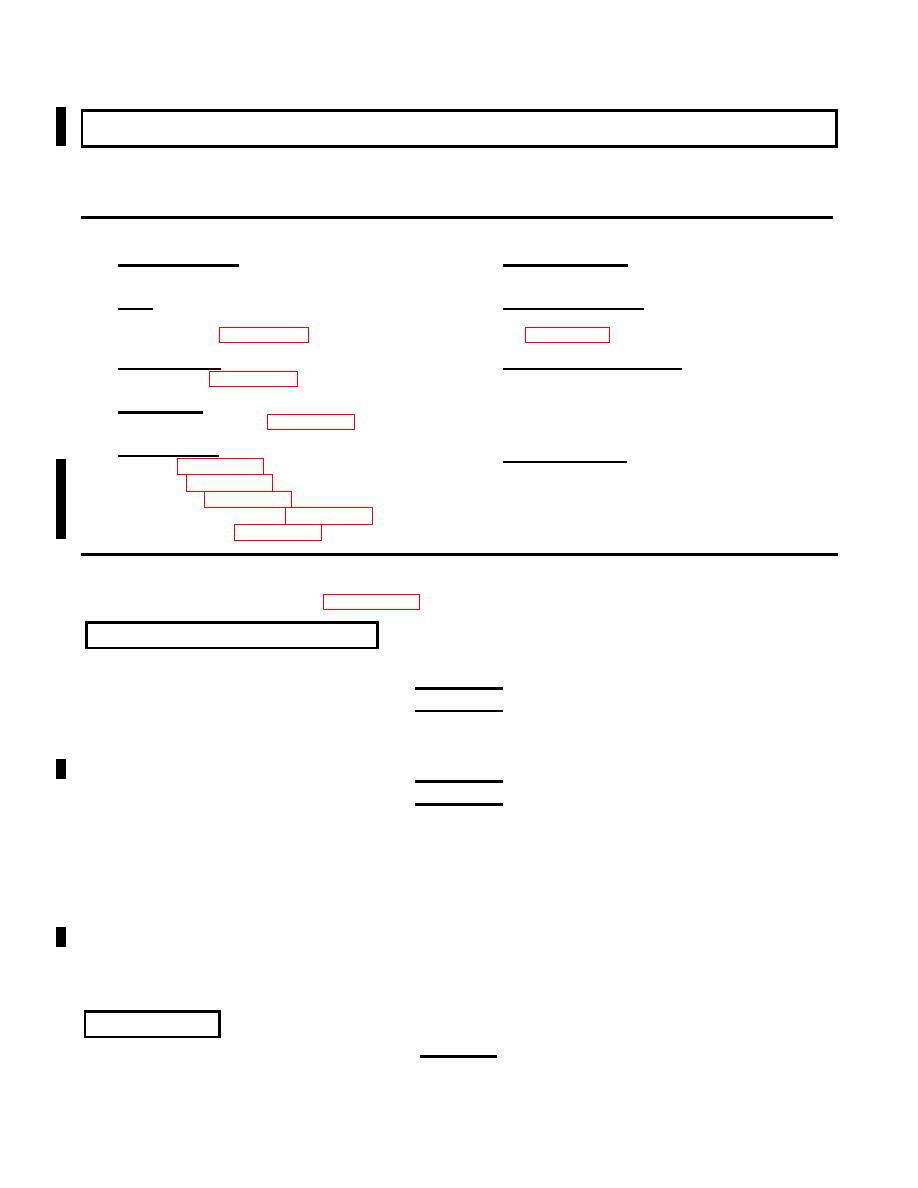

a. Preliminary Inspection and Cleaning

1.

Inspect front of compressor shaft (6) for oil leakage. If oil leakage is evident, replace compressor

shaft seal.

WARNING

Compressed air for cleaning purposes will not exceed 30 psi

(207 kPa). Use only with effective chip guarding and personal

protective equipment (goggles/shield, gloves, etc.).

2.

Clean compressor assembly with lubricating oil and dry with compressed air.

WARNING

Compressor cylinder block may be pressurized. Loosen oil filler

plug slowly. If sound of escaping gas is heard, do not continue

loosening plug until all pressure is released.

3.

Loosen oil fill plug (3) to relieve any pressure buildup in compressor cylinder block (1).

4.

Rotate compressor shaft (6) with ratchet and socket on compressor shaft nut (5). If severe rough

spots or catches are felt while rotating shaft (6), replace compressor assembly.

5.

Remove oil fill plug (3) and O-ring (4) from compressor cylinder block (1) and drain oil from cylinder

block (1) into measuring container. Discard O-ring (4). Record amount of oil in measuring container.

6.

Install O-ring (4) and fill plug (3) in cylinder block (1) and tighten fill plug (3) finger tight.

7.

Inspect oil for chips, metal shavings, and metal particles. Replace compressor assembly if chips,

metal shavings, or metal particles are present in oil.

b. Disassembly

CAUTION

Do not clamp compressor body in vise. Clamp or support only at

mounting ears, with blocks of wood, to prevent damage to

compressor body.

Change 2