TM 9-2320-289-34

5-15.

TRANSMISSION OIL PUMP MAINTENANCE.

This task covers:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection

INITIAL SETUP:

Equipment Condition

Materials/Parts

l Transmission mounted in holding fixture,

l

(See paragraph 5-1 3)

l

l

ToolslTest Equipment

l

l Annular bearing inserter, J-21465-1

l

l Torque wrench

l

l

l Two slide hammers

l

One oil pump seal

One “O“ ring seal

One pump cover gasket

Two oil seal rings

Six rubber-coated washers

Hydraulic fluid (Item 40, Appendix B)

Petrolatum (Item 50, Appendix B)

RTV sealant (Item 57, Appendix B)

General Safety Instructions

l Dry cleaning solvent is flammable and must not be used near open flame. Use only in a

well-ventilated area,

l Wear goggles and use caution during removal and installation of regulator boost valve spring.

• Compressed air used for cleaning purposes should never exceed 30 psi (207 kPa).

a.

REMOVAL 1

NOTE

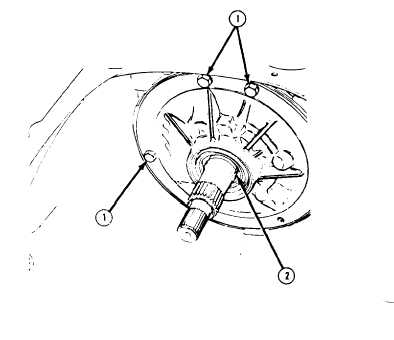

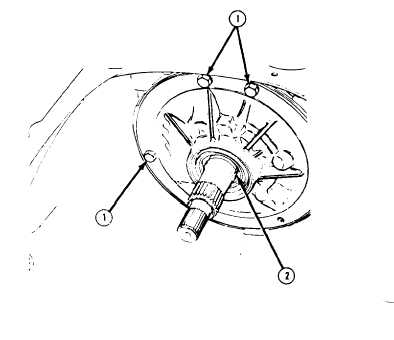

If removing oil pump seal (2), perform step 1.

1.

Remove oil pump seal (2) from oil

pump assembly (3) and discard.

2.

R e m o v e 6

bolts

(1)

and

rubber-coated

washers.

Discard

rubber-coated washers. Install 2 slide

hammers (4) in the 10 o’clock and

5 o’clock positions.

TA60253

5-72