TM 9-2320-289-34

5-9.

REAR SERVO ASSEMBLY MAINTENANCE (Con’t).

b.

BAND APPLY PIN SELECTION CHECK

1.

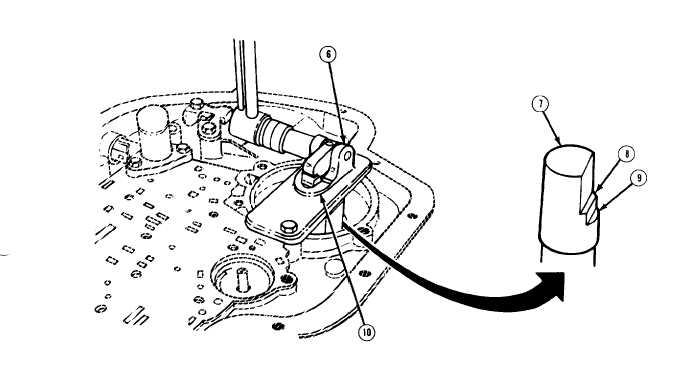

Install pin selector gage (6) over rear servo bore with smaller diameter of gage pin (7) in servo

pin bore and secure with two 5/16 -18 x 1 in. screws tightened to 216 lb.-in. (24 N.m). Ensure

that gage pin is free to move up and down in both pin selector gage and servo pin bore and

that steps (8 and 9) of gage pin and machined surface (10) of pin selector gage are facing

front of transmission case.

2.

Apply 25 Ib.-ft. (34 N.m) to hex nut on side of pin selector gage (6).

NOTE

Identification rings are located on top of servo pin (4).

3 .

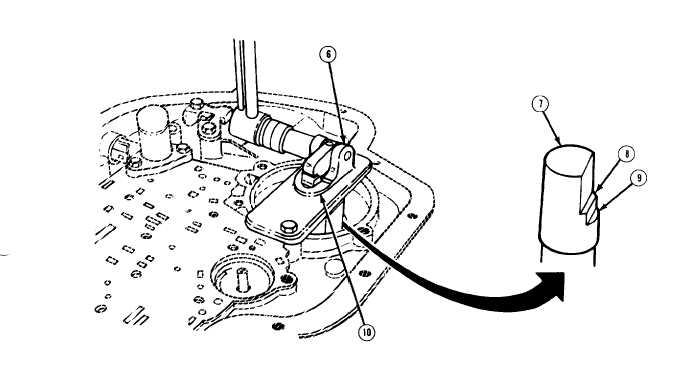

Note relation of steps (8 and 9) on gage pin (7) with machined surface (10) on top of pin

selector gage (6) and determine proper size servo pin (4) as follows:

(a) If machined surface (10) on top of pin selector gage (6) is even with or above upper step

(8) of gage pin (7), long servo pin (3 rings) is required.

(b) If machined surface (10) on top of pin selector gage (6) is between upper step (8) and

lower step (9) of gage pin (7), medium servo pin (2 rings) is required.

(c) If machined surface (10) on top of pin selector gage (6) is even with or below lower step

(9) on gage pin (7), short servo pin (1 ring) is required.

4 .

If new servo pin (4) is required, make note of size. Remove pin selector gage (6) and gage pin

(7) from transmission,

TA50232

5-45