TM 9-2320-289-34

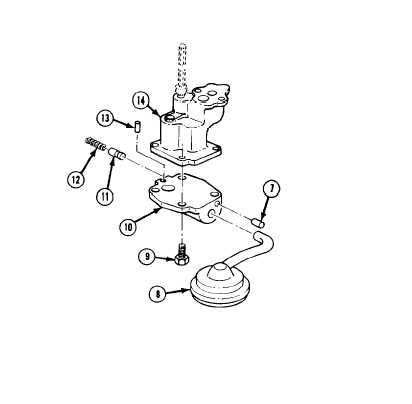

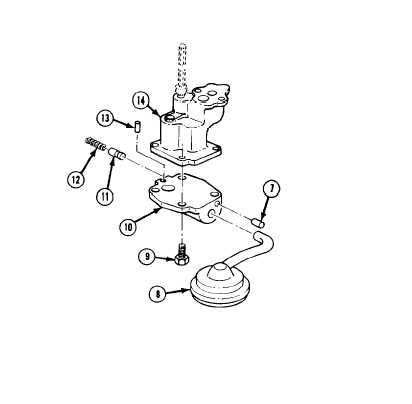

3-33. ENGINE OIL PUMP MAINTENANCE (Con’t).

3. Remove oil pump screen (8) from

cover (10) if damaged.

4. Remove 2 oil pump pins (2) from rear

main bearing cap if damaged.

c. CLEANING AND INSPECTION

WARNING

l Dry cleaning solvent P-D-680 is toxic and flammable. Always wear

protective goggles and gloves and use only in a well-ventilated area.

Avoid contact with skin, eyes, and clothes and DO NOT breathe vapors.

DO NOT use near open flame or excessive heat. The solvent’s flash

point is 100°F-138°F (38°C-59°C). If you become dizzy while using

cleaning solvent, immediately get fresh air and medical help. If solvent

contacts eyes, immediately wash your eyes with water and get medical

aid.

• Compressed air used for cleaning purposes should never exceed 30 psi

(207 kPa). Use only effective chip guarding and personnel protective

equipment (goggles/shield, gloves, etc.). Failure to follow this warning

may result in serious injury to personnel.

1. Clean all components with dry cleaning solvent and dry with compressed air.

2. Inspect oil pump body (14) and cover (10) for cracks, Inspect cover for wear that would permit

oil to leak past ends of oil pump gears. If oil pump body is cracked, replace engine oil pump

(4) as an assembly. If cover is cracked or worn, replace.

TA50709

3-107