TM 9-2320-280-34

e. Hole Countersinking.

NOTE

Some rivet installations in the body require that rivet head be

flush with the material surface, in these instances, countersunk

or flush head rivets are used.

1.

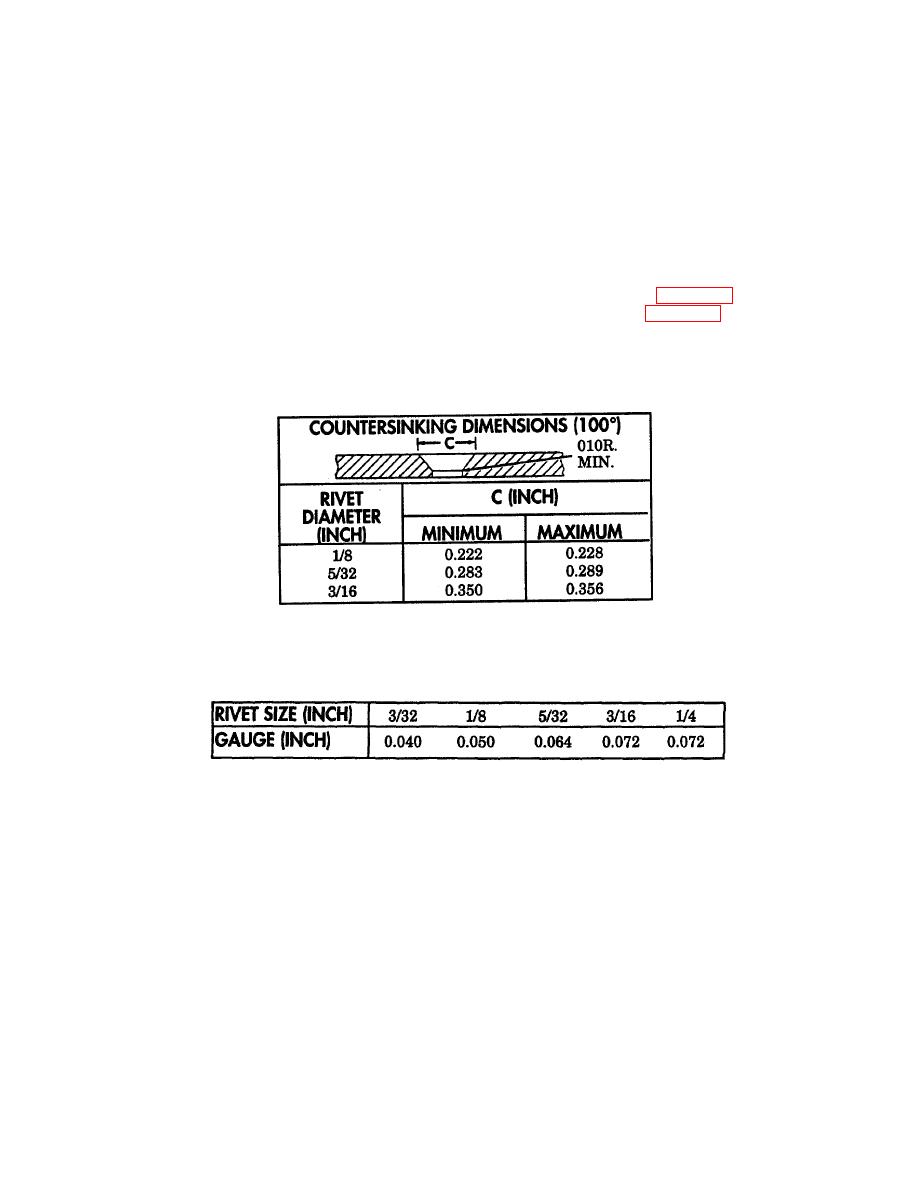

When using countersunk rivets, rivet holes must be countersunk with a tool having a 100taper so rivet

head will fit flush with surface.

2.

When using a hand-operated countersink, the hole must be tried with a rivet so the recess will not be

too deep or too shallow. It is best to use a countersink with a stop on it so depth of countersink can be

controlled. Typical countersinking dimensions for blind rivets are shown in table 22-3. The minimum

sheet thickness that can be machined for 100countersink rivets is given in table 22-4.

3. Do not remove edge of hole on blind side of joint.

100Countersunk Blind Rivets

010R.

MIN.

f. Blind Rivet Driving Practices and Precautions.

1.

Rivets should be inspected for proper installation. The grip length of each rivet is marked on top of its

head to provide positive identification. Use of proper grip length will produce a rivet installation where

locking collar is flush with top surface of rivet head. Tolerance limit on flushness is 0.020 in. (0.5 mm).

2.

For proper rivet installation, it is imperative that holes be properly prepared, tools be in good working

order, and rivets properly applied. When problems occur, the source of trouble could be in any of these

areas.

22-9