TM 9-2320-280-34

21 - 4. FRAME INSPECTION AND REPAIR (Cont' )

d

(b)

Horizontal (bowing) Measurement.

(1)

Select a smooth level surface and drive the vehicle into position from a 12 ft (3.7 m)

straight line of travel. Apply parking brake gently to bring vehicle to a stop. Chock

wheels (TM 9-2320-280-10) and release parking brake.

(2)

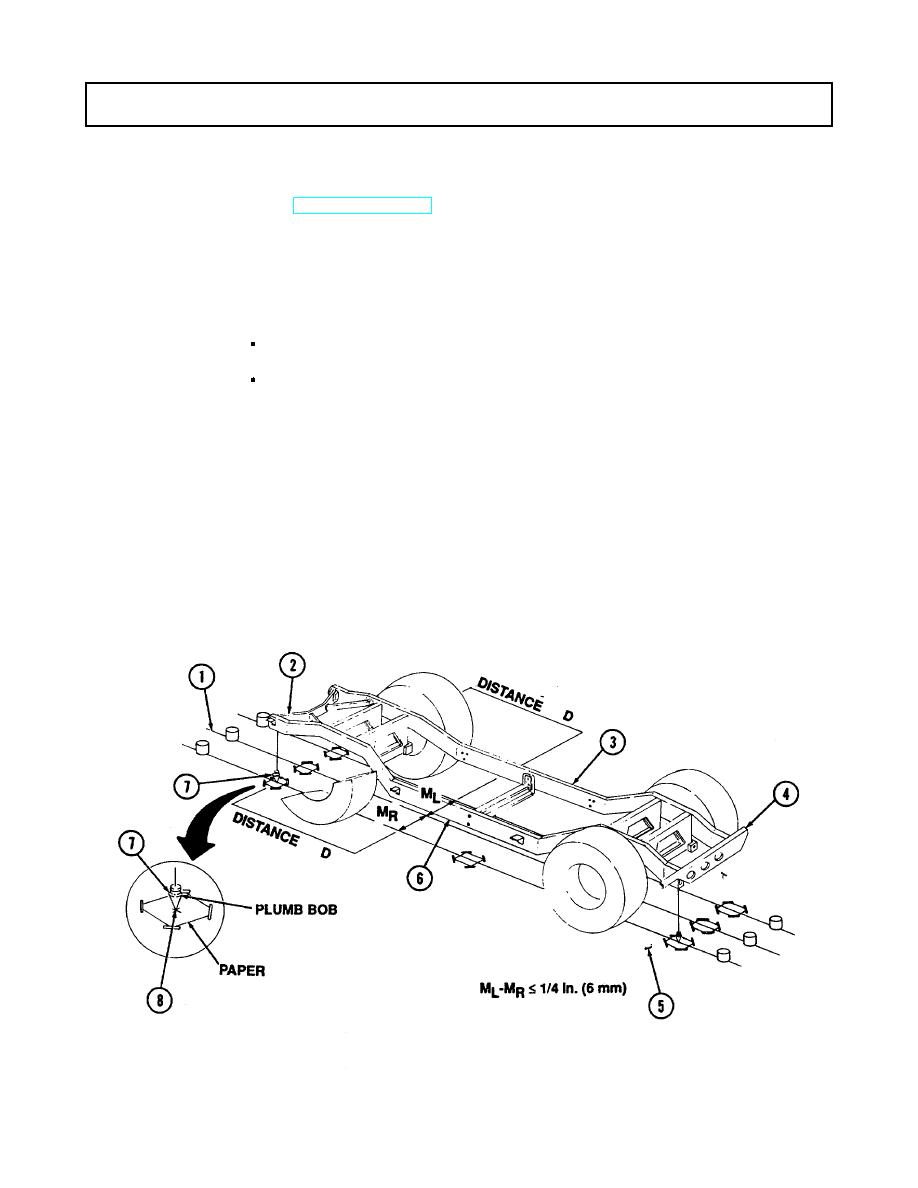

Measure height of frame rails (3) and (6) at each end near center of crossmembers (2)

and(4). If heights vary by more than 1/8-5/16 in. (3-8 mm), jack-up and install

jackstands to bring frame to leveling tolerance (step 2a (1) and (2)).

(3)

Hold a string with plumb bob (7), as shown, along frame rail (6) at intersection of

crossmember (2). Mark location (8) where plumb bob (7) stops moving. Do this for all

four corners of frame.

NOTE

Strings used for horizontal bow measurement will remain in

place until procedure (c), frame skew, is completed.

To ensure measurements are precise, string must be pulled

tight and secured.

(4)

Stretch string tightly on floor (5) between front and rear plumb bob (7) marks under each

frame rail (3) and (6).

(5)

Measure front and rearmost crossmembers (2) and (4) to determine center point. Drop

a plumb bob (7) from these points to the ground. Mark location where plumb bob (7)

stops moving.

(6)

Stretch string tightly on floor (5) between front and rear plumb bob (7) marks under

crossmembers (2) and (4) to determine centerline (1).

(7)

Measure an equal distance along right and left strings to select measure points and

measure from these right and left points to center string. Mark these points on string.

The distance from right and left points to center string should be within 1/4 in. (6 mm) of

being equal. If not, one frame rail is bowed. Repeat this procedure for several other

points along frame. Record deviations.