TM 9-2320-280-34

14-27.2. AIR-CONDITIONING PRESSURE LINES REPLACEMENT (R-134a) (Cont'd)

6.

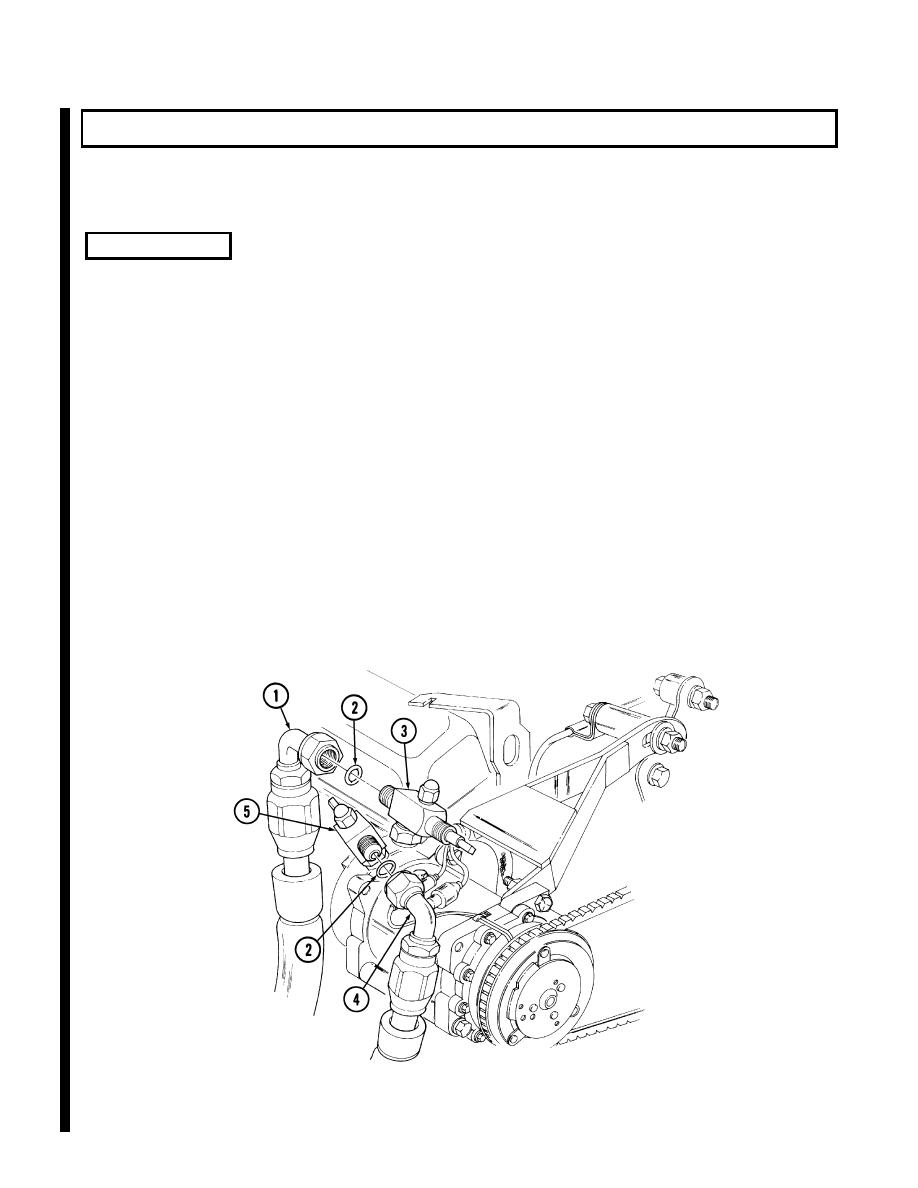

Disconnect suction hose (1) and discharge hose (4) from compressor service valve (3) and service

valve (5) and remove suction hose (1) and discharge hose (4) from vehicle. Remove and discard two

O-rings (2).

b. Installation

1.

Using old pressure lines as a positioning template, install insulation (12) to suction hose (1) and

discharge hose (4).

2.

Install suction hose (1) and discharge hose (4) through grommet (13) and into crew compartment

ensuring that insulation (12) is positioned to prevent chafing of hoses against grommet (13).

3.

Lubricate two O-rings (2) with lubricating oil and install O-rings (2) on suction hose (1) and

discharge hose (4) and connect to compression service valve (3) and service valve (5).

4.

Lubricate two O-rings (7) with lubricating oil and install O-rings (7) on fittings (6). Install and

tighten suction line (8) on fitting (6) to 33 lb-ft (45 Nm). Install and tighten discharge line (9) on

fitting (6) to 20 lb-ft (27 Nm).

Connect discharge line (9) to discharge hose (4) and tighten to 30 lb-ft (41 Nm). Connect suction

5.

line (8) to suction hose (1) and tighten to 45 lb-ft (61 Nm).

6.

Slide insulation (12) on discharge line (9) towards discharge hose (4) and install three tiedown

straps (11).

7.

Install clamp (20) on suction hose (1) and discharge hose (4) on underside of body (17) with

capscrew (14), washer (15), lockwasher (18), and nut (19). Secure suction hose (1) and discharge

hose (4) together with two tiedown straps (16).

8.

Install two clamps (21) and harness clamp (25) on suction line (8) and discharge line (9) on

body (10) with washers (24), lockwashers (23), and capscrews (22).

Change 2