TM 9-2320-280-34

6-5.1. 200 AMPERE DUAL VOLTAGE ALTERNATOR (12447109) TESTING AND REPAIR (Cont'd)

NOTE

When tachometer reaches 3000 rpm, green lamp should go off,

indicating proper charging from alternator.

Normal voltage range is 26-30 VDC. High amperage is +10 percent

over the rated alternator output of 162 amps at 5000 rpm.

9.

Perform full-load test. Ensure all load switches are in ON position on 500 amp test stand, and

increase alternator speed to 5000 rpm. Set load to 81 amps/min; record results. Refer to table 6-E,

Full-Load Test, for diagnosis.

10.

For alternator speed and current output tracking values, refer to table 6-F.

11.

Perform regulator bypass test. Prepare alternator as in full-load test.

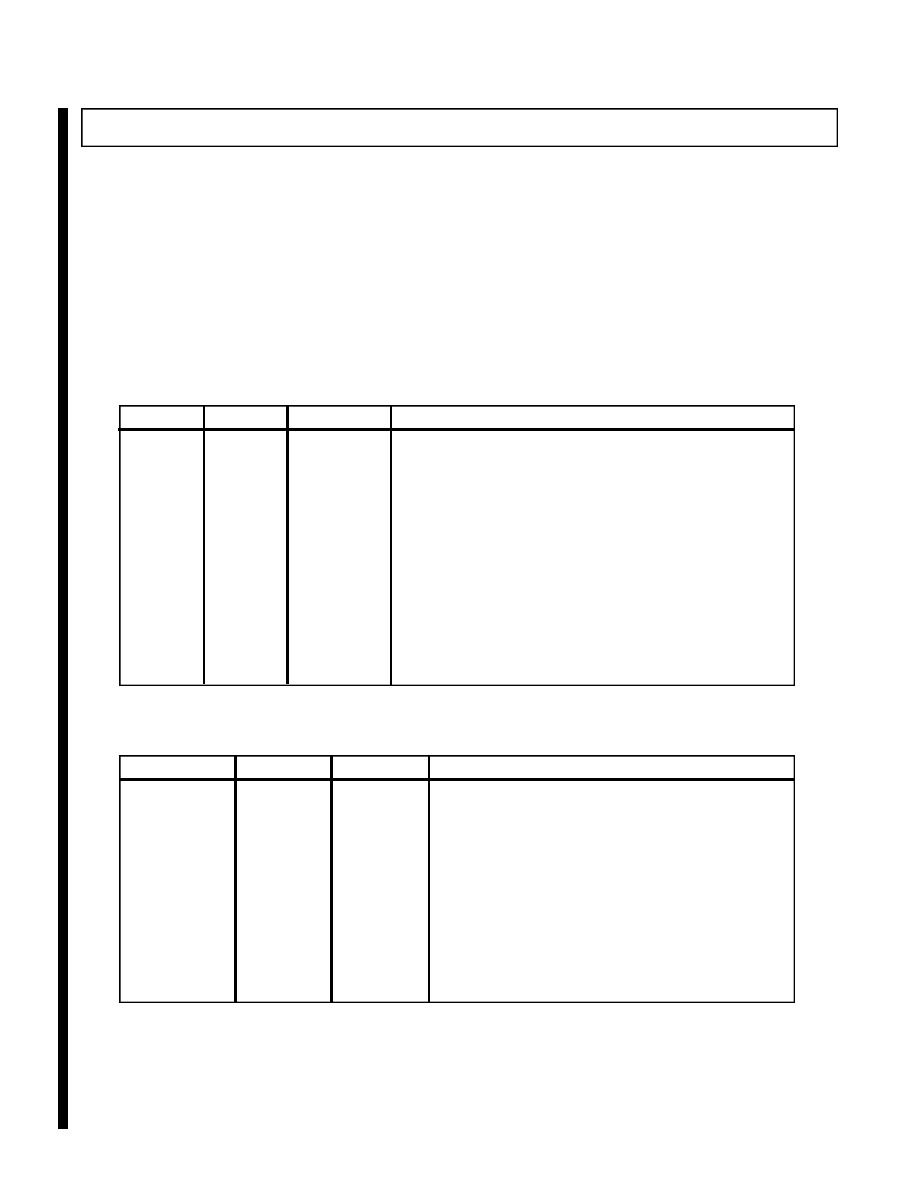

Table 6-D. No-Load Test.

AMPS

28VDC

14VDC

DIAGNOSIS

162-200

21-25

10.5-12.5

Test bench battery is discharged (or defective). Allow

to charge (or replace).

162-200

26-30

13-15

Give time to stabilize while monitoring VOLTS. If

VOLTS rise above normal range (26-30 volts),

regulator and/or tube assembly must be replaced. If

AMPS fall, charging system is OK.

162-200

31-35

15.5-17.5

STOP TEST. Regulator and/or tube assembly must be

replaced. Refer to static testing, task c.

80-118

21-25

10.5-12.5

Alternator and/or regulator must be repaired or

replaced. Refer to table 6-F.

80-118

26-30

13-15

Regulator OK. Refer to table 6-E.

80-118

31-35

15.5-17.5

STOP TEST. Test bench malfunction or wiring error.

Table 6-E. Full-Load Test.

AMPS

28VDC

14VDC

DIAGNOSIS

162-200

21-25

10.5-12.5

Test bench battery is discharged (or defective).

Allow to charge (or replace).

162-200

26-30

13-15

Charging system OK.

162-200

31-35

15.5-17.5

STOP TEST. Regulator and/or tube assembly

must be replaced. Refer to static testing, task c.

80-118

21-25

10.5-12.5

Alternator and/or regulator must be replaced.

Refer to table 6-G.

80-118

26-30

13-15

Increase load.

80-118

31-35

15.5-17.5

STOP TEST. Test bench malfunction or wiring

error.

6-44.4

Change 1